|

|

Forum Index : Electronics : repeat cycle timer

| Author | Message | ||||

| yahoo2 Guru Joined: 05/04/2011 Location: AustraliaPosts: 1166 |

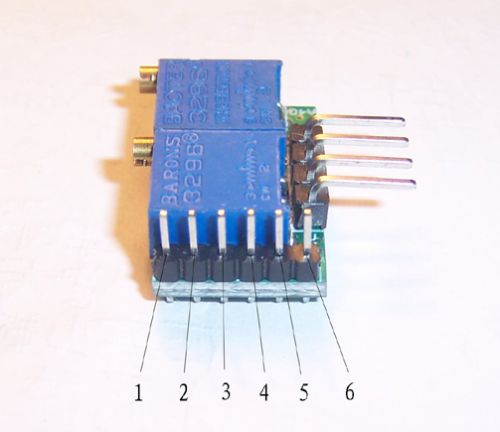

I am looking to drive a facet solid state fuel pump at zero pressure and maybe 5% of its maximum flow. the solution I have come up with is a repeat cycle timer something like this one from bellevue

this will give me a time down to 0.2 seconds and up to 45 seconds for both T1 and T2. I am using it to squirt pulses of fuel into a combustion chamber to run a furnace and perhaps a heater in the future. Eventually I would like to adjust the off time (or both on and off time) with some output from a thermocouple or temperature controller. I am just wondering if that is possible? I have trawled through most of the circuit schematics I can find and I haven't come across anything that will adjust a pulsed cycle. I'm confused, no wait... maybe I'm not... |

||||

| BobD Guru Joined: 07/12/2011 Location: AustraliaPosts: 935 |

That repeat cycle timer looks like it is adjustable only by the screw settings. If that's the case then it doesn't give you much capability of modifying the cycle based on external sensing. Rather than start off with one of those, I would set it up with a microprocessor driving a solid state relay. A Maximite has the capability to provide variable duty cycle pulsed outputs. These could be varied or shut off depending on time of day, temperature sensed, or your mother in law visiting for the day (turn the heat up).

Here is a solid state relay from Jaycar. I am sure that they can be had from fleabay and other suppliers. I suggested a Maximite because it is easier to update the firmware. A Micromite needs some extra equipment for firmware updating but overall it could be a cheaper solution. Any interest in this idea? |

||||

Downwind Guru Joined: 09/09/2009 Location: AustraliaPosts: 2333 |

If you have never used a micro processor i would suggest using a Picaxe chip as they are simple and well supported here and on other forums, a maximite or Micromite is just over kill for this application. Just because the Maxi/Micro is the latest flavor micro chip on the forum dont mean its the best choice for a micro chip beginner and a simple project. I would suggest using PWM to drive the pump as its a simple control with a picaxe, or even Pulsout as it can be a simple solution, or many other ways to code the required result. Pete. Sometimes it just works |

||||

| yahoo2 Guru Joined: 05/04/2011 Location: AustraliaPosts: 1166 |

Thanks BobD, yes the cycle timer is adjusted with two trimpots, I am only looking at using this for prototyping the control system and fully manual operation. Maximite could be a good solution, I have not tackled writing any code for one yet so it might be a tuff introduction. the other two ideas I had are a bit different, the first was to install two of these cycle timers and set one to a "run" setting and the other to an "idle" and use a PID controller to switch between the two. the other idea was to use a stepper motor with a reduction drive and a gear pump to give me the metered doses I am looking for. I'm confused, no wait... maybe I'm not... |

||||

| yahoo2 Guru Joined: 05/04/2011 Location: AustraliaPosts: 1166 |

Hi Pete, I have tried PWM and I struggle to get a pump to flow reliably at really low flow rates. not sure if it is the thickness of the oil or no pressure or running the pump to slow!!! anyway it has beaten me on that path so I am trying a different tack. if I try the gear pump I will give a motor speed control kit a try perhaps, im pretty sure that will work. I'm confused, no wait... maybe I'm not... |

||||

| BobD Guru Joined: 07/12/2011 Location: AustraliaPosts: 935 |

Don't know specifically about your Facet fuel pump but they are generally used to pump fuel with low viscosity, high pressure, and a constant flow rate. They bleed the surplus fuel not used by the injectors, back to the fuel tank via a constant pressure valve. Pumps of this type may not work too well at low pressures and higher viscosities (speculative thoughts). A geared oil pump could do the job. I would use a bleed, back to the tank, downstream of the pump just to keep a bit of oil flowing through the pump and then use an injector solenoid, under microprocessor control, to feed the furnace. |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

I would be using a peristalic pump for this. These come in a very wide flow range, and if driven from a dc motor are readily adjustable for speed and flow. http://en.wikipedia.org/wiki/Peristaltic_pump Check out e-bay, but select "lowest cost first" as some are very expensive, and others are below twenty dollars brand new. They are commonly used in medical and laboratory applications, and very small ones for chemical dosing in industrial applications. It would not be too difficult to make one yourself from a dc hobby motor and appropriate gearbox. They can provide massive pressure at very low flow, and a big one running fast can pump a surprising volume. By fitting various bore flexible silicon rubber tubing to it, you can alter the flow range, and of course speed (with a gearbox) could be one rev every 24 hours if that is what you want, up to several hundred rpm. A very flexible and reliable pump. Cheers, Tony. |

||||

Downwind Guru Joined: 09/09/2009 Location: AustraliaPosts: 2333 |

For example to how simple it is to create a short on time for the pump followed by a longer off time using a 8 pin picaxe chip. This would use 2 x 10K pots configured as voltage dividers to adjust the times, one for "on time" of between 0-1024 milliseconds (up to 17 seconds) and another pot to adjust the "off time" in seconds from 0-1024 seconds. With a solid state relay to do the switching for the pump on/off. The basic code required would be something like this. #picaxe 08m2 symbol time_on = w0 symbol Time_off = w1 symbol adc_on = C,1 symbol adc_off = C.2 symbol SS_Relay = C.4 Main: readadc10 adc_on, time_on readadc10 adc_off, time_off high SS_Relay pause time_on low SS_Relay wait time_off goto main This would run the pump for what time frame was set for time on and then wait the set time off period before repeating the time on function again. All for about $10.00 in parts. Edit... To add schematic Pete. Sometimes it just works |

||||

| yahoo2 Guru Joined: 05/04/2011 Location: AustraliaPosts: 1166 |

Thanks everyone, I will have a close look at what you have posted and a think about it tonight. I have been away on a solar install for a couple of days (beyond the interweb). Few things to catch up on at home before I can pull the workboots off and spend some time in front of the computer. I'm confused, no wait... maybe I'm not... |

||||