|

|

Forum Index : Electronics : Induction motor part dead-help!

| Author | Message | ||||

| domwild Guru Joined: 16/12/2005 Location: AustraliaPosts: 873 |

Hi, 3/4 HP, 240VAC pedestal drill, cheap model. Belts used to slip when overloaded but this time I could not switch the drill off fast enough. Now motor either hums, or starts but can be stopped by hand, i.e., no power or turns when helped. Two caps: 50 uF motor start cap, 250VAC, other 12 uF 450VAC. Caps got hot. If the forum suggests the reason for not working is the cap or caps, then how do I test the cap/caps seeing that I am working with 240VAC? Or did I burn out the windings and can most likely throw away the motor? Thanks. Taxation as a means of achieving prosperity is like a man standing inside a bucket trying to lift himself up. Winston Churchill |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

Dont sound good

If you multimeter has a capacitance range, you could measure the caps to see if they are within spec, give or take. Taken out of circuit of course. But I would guess there is a short in the windings. Once they get a short, they are history usually, as the shorted turns overheat, and cause a breakdown in the insulation of other turns, then they overheat, etc. But, induction motors are plentiful, and you should pick up a old one pretty cheap. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

Downwind Guru Joined: 09/09/2009 Location: AustraliaPosts: 2333 |

Ok lets break it down, you have a start winding with a start cap and normally the smaller cap is on the start winding. (12uf ) Then you have a run winding with the larger cap. (50uf) As Glenn has implied you may have cooked the start winding, although it could be the start cap faulty, but not as likely as a winding fault. If you have another cap from a motor handy (12uf to 20uf) or several caps you can parallel together to give the uf, then you could try a start cap replacement test. It could also be worth removing the back of the motor and checking the primary start winding switch has not welded its contacts together, its a centrifugal switch that requires RPM to disengage the start winding once up to speed. One can only expect the motor was in a stall mode for some time to cause a problem, this is why i have a foot control pedal for my drill press, as there is times you can not let go of the work to have a free hand to switch the drill off, but you can always step off a pedal switch. Pete. Sometimes it just works |

||||

| domwild Guru Joined: 16/12/2005 Location: AustraliaPosts: 873 |

Thanks for help. Will check the centrifugal switch and caps and if U/S then I hope I can find a motor with the right shaft diameter, RPM (1400) and size to mount. Taxation as a means of achieving prosperity is like a man standing inside a bucket trying to lift himself up. Winston Churchill |

||||

| domwild Guru Joined: 16/12/2005 Location: AustraliaPosts: 873 |

So far checked the centrifugal switch and that appears to be OK. Next I shall by a meter with capacitance. From the little I saw of the windings, they look OK. Question: Looking at catalogues and they talk of "capacitor start" and CS/CR, which I guess means cap start/cap run. For a drill should I look for one or the other or should I just be happy that it has the horsepower, RPM and foot mount?? Taxation as a means of achieving prosperity is like a man standing inside a bucket trying to lift himself up. Winston Churchill |

||||

| Georgen Guru Joined: 13/09/2011 Location: AustraliaPosts: 462 |

There are few 'inexpensive' methods to roughly check mains voltage capacitor without the need to buy special Multimeter (unless you waited to buy one and needed legitimate excuse to do it :) ) One of the web pages talks about it in some detail here: http://www.electricaltechnology.org/2013/06/how-to-check-cap acitor-with-digital.html George |

||||

| kitestrings Senior Member Joined: 23/04/2014 Location: United StatesPosts: 102 |

An analog meter multi-meter can give you a pretty good idea if the start cap is spent. Good to short it first to discharge anything that might effect the meter in a not-so friendly way. Haven't looked at one in a while, but on a mid-range ohm scale (Rx10, Rx100) you will normally see the meter peg right (-0- ohms), then start to "bleed" toward left (infinite resistance). If you've ever used one of those inexpensive testers, they don't do much more. They have audible high to low pitch sound. I find this to be more helpful than a bunch of dancing number on a digital meter. Good luck, ~ks |

||||

| Pete Locke Senior Member Joined: 26/06/2013 Location: New ZealandPosts: 181 |

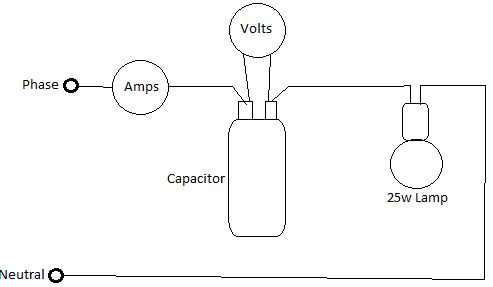

There is a fairly simple way to check mains rated caps. All you need is a 25watt lamp, a basic multimeter and a bit of a formula. 1/ Connect the circuit as shown with the capacitor in series with the lamp and a known AC voltage at the phase and neutral . Mains is good as itís a known voltage and frequency. 2/ Turn it on. The lamp should glow. This will at least tell you there is something for the electrickery to get through. 3/ Measure the AC voltage across the capacitor and note it down. 4/ Measure the current through the circuit and note that down as well. These are the only two numbers you need. Now to work out the value. 1/ Calculate the resistance as follows. Resistance = Voltage/Current. So if you have say 20volts measured across the capacitor and a circuit current of 0.1amp you will have a resistance of 200ohms. 2/ The capacitance can now be calculated using C=1/(2x PI x mains frequency x Resistance) So 2x3.1415x50x200=62830 1/62830=0.0000159 This is the answer in Farrads. If you move the decimal point to the right by 6 places, you will have the answer in Microfarads. In this case near as damn it 16uF.

|

||||

| domwild Guru Joined: 16/12/2005 Location: AustraliaPosts: 873 |

Thanks for help with the measurement of capacitance. Any idea if a motor for a drill has to be a cap start only or must be a cap start/cap run? The existing dead one is a CS/CR, i.e., two caps model. I might not be able to get the caps with the precise capacitance from Jaycar/Fleabay, is this a critical figure as far as torque is concerned?? Anyway, at the moment I am still optimistic that the motor is not dead and will concentrate on the cap/caps. Taxation as a means of achieving prosperity is like a man standing inside a bucket trying to lift himself up. Winston Churchill |

||||

| domwild Guru Joined: 16/12/2005 Location: AustraliaPosts: 873 |

Hi, Fixed! First bought a new multimeter as I could not measure AC Amps with my $10 one. The new meter has capacitance included. The 12uF one measured OK. The 50uF measured 3nF! The suggested schematic with lamp and the resulting calculations as suggested led to a weird 4000mF value and this is not an error in decimal places. Anyway, the dead 50uF start cap was replaced with two paralleled 20+30uF starter caps from Jaycar and the motor spins again! The original 50uF cap fitted into a small plastic tube alongside the motor, the two and big new caps will have to be safely tucked away somewhere. Thanks for help! Taxation as a means of achieving prosperity is like a man standing inside a bucket trying to lift himself up. Winston Churchill |

||||

| Pete Locke Senior Member Joined: 26/06/2013 Location: New ZealandPosts: 181 |

Great to see you have the hole making thing going again. Don't understand why the calculations didn't work though. The formulae does assume that you are dealing with sine waves as anything else can give incorrect readings on general meters. But you're back making spaces in bits of material which is the main thing :-) |

||||

| domwild Guru Joined: 16/12/2005 Location: AustraliaPosts: 873 |

Pete, I cannot understand that either and guess that a faulty cap may give erroneous readings. The formula of 1/2 * PI etc. reminds me of high school, where the physics teacher talked about pendulums and sine curves. Taxation as a means of achieving prosperity is like a man standing inside a bucket trying to lift himself up. Winston Churchill |

||||