|

|

Forum Index : Electronics : .75 Kw VEVOR VS 802-4. noisy and rough running

| Author | Message | ||||

| brucedownunder2 Guru Joined: 14/09/2005 Location: AustraliaPosts: 1548 |

I hope I'm in the correct section of the forum ?. I have a new electric motor to be fitted to my wind generator tower for up/down operation. I have been careful in connecting to the motor control terminals, but could be wrong ?(tried a couple of different connections ,but it still runs ONLY clockwise , AND very rough ,(because of this I just touch the switch to test it ,no longer than ,maybe, a second. I've lost contact with my work mates and so I'll see if we have any motor electricians lurking on the forum. Been absent from the forum for couple years, I'm crook with Kidney failure, so attend hospital three days per week for Kidney Dyalysis. for ever !! and they cancelled my drivers licence !. I feeling ok around the house and my workshop ,still busy building stuff, but can see the time coming when we have to move into some home smaller ,not happy . Anyhow , wish you all well, Bruce and Ilda Bushboy |

||||

| Godoh Guru Joined: 26/09/2020 Location: AustraliaPosts: 458 |

Hi Bruce, first question is this a single phase or three phase motor? Getting a single phase motor to reverse direction generally means changing the relationship between the starting winding and run winding. Three phase motors only require two of the phases to be swapped. It sounds like you have the connections wrong.' Single phase motors sound rough when starting because they don't have a rotating magnetic field like a three phase motor. They only have a pulsating field between the start and run winding. Get back with a bit more information if you can Pete |

||||

| brucedownunder2 Guru Joined: 14/09/2005 Location: AustraliaPosts: 1548 |

Yes,thanks Peter, First I have to get the motor windings and start relay connections . Then,see if I can manage to connect Forward. And. Reverse. Correctly designated terminal Sheet, where will I get this? I tried Vovor for this info.. no luck.,just did not know where to search. .? I,m marrying this motor to a DRUM switch.,the popular 10 terminal GS 60 . On e bay. Thanks for your assistance, Bruce Bushboy |

||||

| Godoh Guru Joined: 26/09/2020 Location: AustraliaPosts: 458 |

I am guessing that it is a single phase motor then if you are talking about a start relay. Is it possible for you to post a photo of the terminal block, so that i can see which wires are there? I just looked at photos of the GS60 drum switch, they appear to be for 3 phase motors. If you can attach a photo of the motor, terminal block and nameplate that will help Pete |

||||

| Godoh Guru Joined: 26/09/2020 Location: AustraliaPosts: 458 |

Hi Bruce, here is a manual on motor connection and terminal markings, hopefully this will help Pete Terminal_Markings_and_Motor_Connections.pdf |

||||

| brucedownunder2 Guru Joined: 14/09/2005 Location: AustraliaPosts: 1548 |

Hi Pete, I,ll attach some pics of my work bench and the new motor and new Drum switch . I,ve done extensive changes to the connections between motor and motor connection block ,but have not changed any factory wiring to the block ,just the brass links,which I have removed as the Drum switch Instructed. Off to Hospital for torture., at least the nurses are so kind and understanding, 4 hours of draining my blood and cleaning of toxins , I suffer from sever cramps during this procedure, and can,t move as I,m strapped in to prevent my tubes from disconnecting . I,m stumped, so without help. I really am stumbling in the dark. Thank you Bruce Pics can,t be loaded, I,ll have to send them to someone on the forum to load them for me ,, off to hospital Bruce Edited 2023-03-10 21:40 by brucedownunder2 Bushboy |

||||

| brucedownunder2 Guru Joined: 14/09/2005 Location: AustraliaPosts: 1548 |

Hello, I see to be trying to post pics taken from my I pad that are too large. In Pixels. Can someone show me how to get the IPad to resize them ? Thank you Bruce Bushboy |

||||

| Godoh Guru Joined: 26/09/2020 Location: AustraliaPosts: 458 |

Hi Bruce , I don't use an ipad but this video seems to say that it is pretty easy hope it helps Pete tch?v=Go6z2hXo2sU] sorry links don't seem to want to work so just copy and paste the text from HTTPS on. |

||||

Revlac Guru Joined: 31/12/2016 Location: AustraliaPosts: 1024 |

Bruce, you can send me the pictures if you like, I can resize them or post them.  Cheers Aaron Off The Grid |

||||

| Murphy's friend Guru Joined: 04/10/2019 Location: AustraliaPosts: 648 |

Both links work fine here but I did not watch whatever that dog was up to. I use a free program called Irfanview. This lets me reduce pictures to whatever size I want (600 x xxx for this forum uploads) and then save them in the preferred format (jpeg). Renaming and save as to desktop lets me find it easily to upload. |

||||

Revlac Guru Joined: 31/12/2016 Location: AustraliaPosts: 1024 |

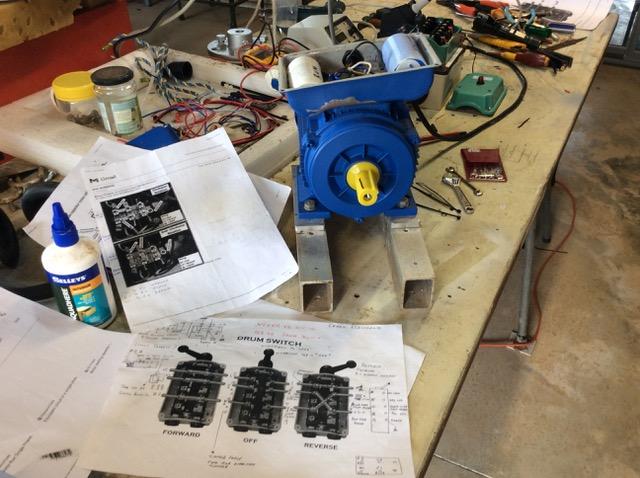

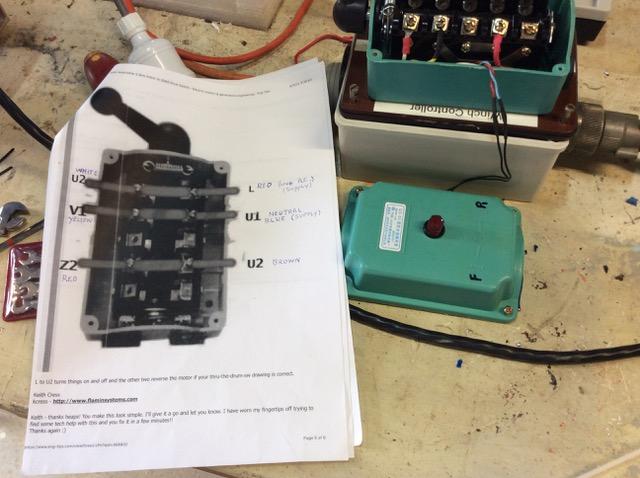

This is the Drum switch and some idea of connecting it to the terminations on the motor . The motor requires a cross-over of active and neutral , so this arrangement ,plus a couple of extra links , are required on this drum switch top termination hardware- There being ,in my case, raise - off. - lower . I added a neon to show Power is on ., on the lid cover ,the green cover.  Here I show the new motor , a Vevor VS 802-4 , The Drum switch is a QS 60 , ( on the internet), most of my stuff is sourced from the searching the internet. The motor came from aliexpress. Plus the drum switch - unfortunately, I did not realise no circuits ,drawings, information at all , came with switch and motor, sad. Pic showing my 1 mtr length of 7 conductor trailer lighting cable to a couple of waterproof cannon military plugs to disconnect the switch unit from the motor for storage ,when wind generator tower is up or down and in use or stored for maintenance.  This pic is of the Capacitors ,start and run , and how they can be wired to this motor, they were wired from factory, plus links to run motor clockwise. I have searched the internet and think I have it running clock and anti-clock with no discernible noise coming from the running.   In the end, through frustration, and after trying many many combinations of connections , I broke my law and used a live power probe to get it running . Some very gentle touching of the active probe , prevented tripped breakers in my workshop. 50 years does teach you CARE. I have not finished the wiring as , hospital treatment is taking half my week, I’m finding it very hard to take , and besides it’s painful having tubes inserted every session day ,ten no moving for 4 hours ,you are velcro strapped in ,300 ml of your blood is at any time out of your body and being cleaned in the machine plumbed to your body. Anyhow , I’ll let the more talented look at my project and maybe agree with present progress or suggest alternate connections. I used to have a RPM meter, but some lucky mate, has forgotten who it belongs to , I guess.  This was a pic of when I first started on the project, things have been moved around a bit . I take a long time to get things done. Thanks to the backshed mates who came to my assistance a couple weeks back , I won’t forget. And , of course ,Aaron , a long time friend and wealth of knowledge, along with his Dad,Ron. Thank You. Bruce and my wonderful caring wife and forever driver, they took my licence off me, health reasons. Edit: Bruce, I may have some of the photos out of order, but should be ok. Some of The photos actually come through at 640 x 480, so a little small, I think anything up 1024 x 768 is ok.  Hope this helps Cheers Aaron. Edited 2023-03-17 19:10 by Revlac Cheers Aaron Off The Grid |

||||

Revlac Guru Joined: 31/12/2016 Location: AustraliaPosts: 1024 |

Been busy with things, had a look at a roller door motor and it is reversible by a pair of relays on a circuit board (and some other electronics) but has a run capacitor only. Bruce, The diagram Godoh posted, page 8 should be mostly the same as your motor with the start and run capacitors, should only need the wires for the start winding switched? If the motor is running rough, it might be the run capacitor not connected or working properly.....just a guess. I will have another look later. Cheers Aaron Off The Grid |

||||

| Godoh Guru Joined: 26/09/2020 Location: AustraliaPosts: 458 |

Hi Bruce , sounds like you have it running. The basics of a single phase cap start cap run motor are. The capacitors are in series with the starting winding, there is a starting switch that turns the starting capacitor off when the motor gets up to speed, leaving the run capacitor in circuit. To reverse the motor the easiest way is to find the run winding and change the two leads over. Leaving the start winding as it is. The switch will just change the relationship between the start and run winding. If the current flows one way through the winding it will rotate one direction, if you change the direction of current in the run winding leaving the start winding the same then the motor will run the other way. Basically your are making the start winding either lead or lag behind the run winding. The position of the windings and the capacitors cause the windings to simulate a rotating magnetic field. If one winding leads the other then the motor will turn, if the same winding lags the other winding then it turns the other way. Anyway it seems that you have it running, well done. Oh and well done on staying alive while doing it. Pete |

||||

| brucedownunder2 Guru Joined: 14/09/2005 Location: AustraliaPosts: 1548 |

Thank You Pete and all my friends that take the time to care. I'm having a rest from worrying about finishing the reversing drum switch, sort of small jobs around the property are consuming my couple of free days. But my dialysis sessions are improving weight and sleeping, along with lowering my fluid weight, which they say is causing my horrific leg cramps.. The motor is running smoothly,I think so , but I have not yet connected the reversal drum switch, to check for correct operation for connecting to my wind genny tower. Lots of 3/4 inch holes to drill in the steel work ,which I might source a magnetic drill for this task. ( any one got one that I can hire or loan). I get driven to and back from the hospital three days a week now , so I'm extremely thankful for my health care provider for this -Ilda,my wife ,used to do this horrible job and sit at the hospital five hours each day , far too long a time , but there was no other way. now she is free to enjoy time around the house and shopping. Ok, I'm happy tinkering around my place , if you are in the area and wish to visit ,Sunday and Monday are my free days. give me a call ,pick up Arron on the way, we'll put lunch on. Bruce and Ilda Bushboy |

||||

| Godoh Guru Joined: 26/09/2020 Location: AustraliaPosts: 458 |

Hi Bruce, I hope the treatment keeps on helping with your quality of life. Leg cramps may be helped by Epsom Salt baths or by rubbing magnesium oil onto your legs. I don't know much about kidney disease but I get knots in my calf muscles at night and the magnesium helps a lot. Good luck with the tinkering, it is a great activity that can bring lots of pleasure cheers Pete |

||||