|

|

Forum Index : Electronics : Newbie to the but not power electronics...

| Page 1 of 3 |

|||||

| Author | Message | ||||

| teapot Newbie Joined: 22/08/2021 Location: United KingdomPosts: 22 |

Hi, Let me introduce myself. My name is Paul, I live in the east of England. I've been experimenting with off-grid solar power (and auto switching between grid an off-grid for some circuits in the house for at least 3 years now. All leaning tme... I started off with a secondhand (2013 model v3 powerjack 8000 chinese watt inverter, 4 220Ah truck batteries (didn't last long), four 60 cell panels and an epever 4210AN charge controller. It didnt take me long to find the shortcomings of all these components. Ironically, despite PJ's reputation for inverter failures, that is the one component that has stood the test of time (with minor mods to the cooling system and the well documented mod to the resistor ladder to increase the output to about 248V AC. In terms of performance, it's now as good as running on-grid here. No clipping of the sine wave until about 2.5kW load, unlike the newer PJ inverter I purchased in December 2020 which has a single transformer with total iron mass much less than the two transformers in the older PJ. I also tried 2000w 'Pro Mariner' but this proved woefully inadequate, cutting out even with a 2000w induction hob. I've now upgraded to 8x 60-cell panels, and 6x 200Ah gel 'solar' batterie in a 2S4P configuration with 15A fuses per string, So far all has been well except for the need to return to grid power during extended overcast periods which are common here in the UK. My only gripe about the old pJ inverter is its idle current, which is a stubborn 2.5A at 24V. I have tried adding an inductor as suggested on this an other forums but although it reduces the idle current it gets hot and creates a nasty spike/dip on the rising edge of the sine wave. So I have opted to omit it for now. With regards to the newer PJ, I have obtained a nice transformer with a 21x80x80 core (52cm2 CSA) onto which I am using formulae published by 'oztules' tto rewind to my requirements and all being well replace the undersized transformer in the new PJ, as well as keeping idle current sensible. I will keep you posted as to my progress... Edited 2021-08-24 08:18 by teapot |

||||

| Godoh Guru Joined: 26/09/2020 Location: AustraliaPosts: 458 |

Hi Paul, sounds like you are having fun. I have used powerjacks for quite a few years too, I have blown one up twice now but that was caused by my circular saw and a dip in supply voltage trying to start it. I have a 24 volt system with 660 amp hour VRLA batteries. I recently added a 500 Farad capacitor bank in parallel with the batteries, they are doing a great job of preventing voltage dips and supplying starting currents. My compressor now just kicks into life with no problems at all, before the capacitor bank it struggled a bit when starting. The capacitors I have are rated at 1900 amps max, they should theoretically extend the life of the batteries a bit, as they won't be so stressed by starting loads. Our place is totally off grid so I have around 5kw of panels, we don't need anything like that in sunny weather but live in the mountains where fog and clouds are common. So far I have not needed to use a generator since upping the solar panel size. It will be good to hear how you go with the transformer wind. Pete |

||||

| teapot Newbie Joined: 22/08/2021 Location: United KingdomPosts: 22 |

Well this will be my first ever transformer wind, so I'm expecting a bit of experimentation as the theoretical values never match reality. But I have a complete spare set of PJ 8K boards which I recently boutght a complete spare set of PJ 8K boards in case I really mess up. But that's like insurance - I won't need them! In which case I will build another inverter and take to our 2nd home in Uganda one all this covid BS calms down. I like the idea of adding a capacitor bank, sounds like a good idea especially if starting large motor loads (e.g. a well pump). In my case it's just a hobby as we live in a suburban area and have reliable (an currently affordable) grid power and mains water/sewerage. But if the former becomes unreliable or expensive, at least we have a fallback. |

||||

Revlac Guru Joined: 31/12/2016 Location: AustraliaPosts: 1024 |

It would be good to test the transformer with grid power(soft start don't blow something up) or a small generator to see what the idle current really is. Have wound a 52cm2 core and tested idel current of 7w at 235VAC, so running as a 48v inverter that would be about 21w plus a little more for electronics if the choke is doing its job. Edited 2021-08-24 09:10 by Revlac Cheers Aaron Off The Grid |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

If you use Oztules formula, chances are you will see little or no improvement in idling current. The reason for that is he reverse engineered commercial transformer designs to come up with his rules of thumb regarding turns and voltage. Don't wish to take anything away from Oztules efforts, what he achieved is monumental, and he has earned for himself a very conspicuous place in home brew PWM inverter history. However time marches on, and we have made rapid strides since the early days in magnetics design. Inverter transformers are very different from normal commercial transformers that are made to be as low cost as possible using minimum iron and copper. By reducing the flux density from typically 1.5 to 1.7 Teslas, down to 1.0 Tesla, the idling current can be greatly reduced typically to one third or one quarter. People here are routinely building 5Kw inverters with about 30 watts of idling power. In the old days 80 to 100 watts idling power was regarded as being pretty normal at a similar power level. Aarons figures above are definitely achievable, 7 watts idling for the bare transformer plus whatever all the electronics requires in addition to that. I suggest you use the following flux calculator, or something similar, with the appropriate entered values as an example. https://www.daycounter.com/Calculators/Max-Flux-Density-Calculator.phtml Vrms 235 Freq .00005 Mhz (decimal point + four zeros) Turns 203 Ac 52 cm^2 Answer Bmax 10,028 Gauss, very close to our desired 10,000 Gauss (or 1.0 Tesla in metric). Of course you may decide on a different secondary voltage, and number of turns, but it will probably still end up around 200 turns on your 52Cm core. You can go lower than 1 Tesla and reduce idling current even further, but the extra turns take up more space. Eventually the law of diminishing returns kicks in, but 1.0 Tesla is a good starting point. That decides flux density. For current density in the wire, about 4 amps per square mm of copper would be about right. Overall transformer ratio probably about 16:1 for a 24v inverter and a lead battery. These design figures have been used successfully by a great many Forum members for many years with excellent results. 203 turns divided by 16 = 12.68 turns. Suggest 13 turn primary and 208 turn secondary on 52Cm ^2 core. Edited 2021-08-24 09:42 by Warpspeed Cheers, Tony. |

||||

| teapot Newbie Joined: 22/08/2021 Location: United KingdomPosts: 22 |

Here is the spreadsheet I made to do the calculations. It references Oztule's basic formula but I have added some extra stuff (e.g. to calculate approximate wire length/weight and recalculate turns for different flux density). |

||||

| teapot Newbie Joined: 22/08/2021 Location: United KingdomPosts: 22 |

transformer calculator v3.zip |

||||

| teapot Newbie Joined: 22/08/2021 Location: United KingdomPosts: 22 |

Yes I used that calculator to aim for about 10000 gauss. I decided to aim for 240V rather than 235V RMS as the grid here is typically 245-248V RMS and it confuses my wife timing the microwave if there is a significant difference in voltage between on and off grid (down to about 225V before modding the old PJ) - usually resulting in a soiled microwave when we do run on grid power! Plus the inverter lives in the garage, with a run of 45m of 4mm2 SWA back to the house so there is a few volts dropped there under heavy load. I'm happy with the old PJ outputting 248 volts as it only drops to 243V RMS at the house even with a ~2kW load. Edited 2021-08-24 19:27 by teapot |

||||

| Haxby Guru Joined: 07/07/2008 Location: AustraliaPosts: 423 |

Can I just get a clarification of the dimensions of the core. Is it a toroid? You mentioned: 21x80x80 core (52cm2 CSA) Is that 21mm high and 81mm diameter? What size hole? |

||||

| teapot Newbie Joined: 22/08/2021 Location: United KingdomPosts: 22 |

It is 21cm outer diameter, 8cm hole diameter, and 8cm high |

||||

| teapot Newbie Joined: 22/08/2021 Location: United KingdomPosts: 22 |

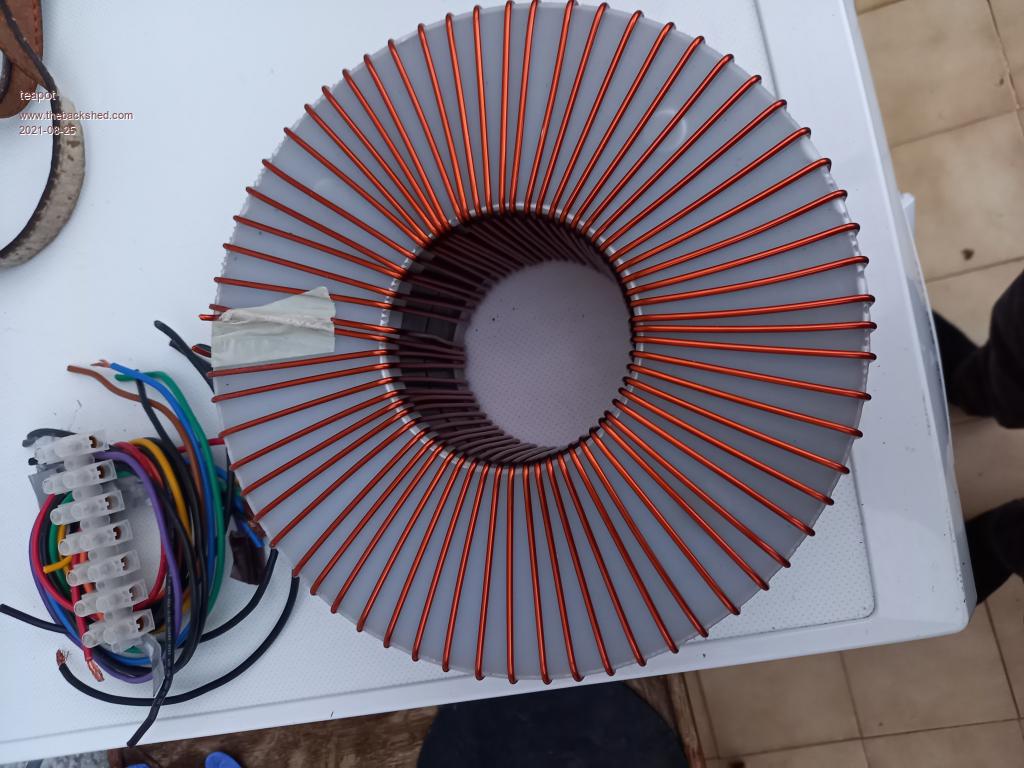

I had not finished removing old windings when I took this photo |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

I forgot to hit the notify button, and so missed the last few posts. The transformer design voltage is only an initial target to aim for, its not set in stone, the exact final ratio is more critical. Once its wound, you can tweak the actual final output voltage above or below that, to whatever you like. The grid is notorious for going up and down, and most things will work just fine over a pretty wide operating voltage range. O/k on the 80mm hole. Primary and secondary should in theory have equal copper areas through that hole. If we divide 80mm into two equal areas, the primary must fit within a hole that is 0.7071 of the original hole diameter. So after first putting on the secondary, the remaining hole left for the primary should end up being approximately 57mm in diameter. This gives us some basic mechanical limitations for the secondary winding. The allowable stacking of the secondary winding(s) must not be more than 80mm minus 57mm divided by two = 11.5mm. The smallest circumference of the final secondary layer will be 57mm x 3.142 = 179mm. The thickest wire we can use might be something like 179mm divided by the required turns, maybe 0.8mm wire? or perhaps 223 max turns fit theoretical. If we have 0.8mm wire that will have an area of 0.5mm sq. At four amps per mm sq we get 2 amps per secondary layer. Be generous, there may only be 210 turns or example, and theoretically 223 turns should fit in that available space leaving a 13 x 0.8mm = 10.4mm gap. The turns will never be up close and snug, and you need some extra space as there will be 240v across that gap. How many layers will fit without exceeding 11.5mm build thickness might be around ten, as a wild guess, allowing for insulation between layers and some lumpiness in the wire. Just keep adding layers until the final hole remaining shrinks down to 57mm. More than ten layers might fit, but don't be too surprised if you struggle to get even to ten layers. So with luck, and ten two amp layers, a 240v 20 amp secondary might be possible = 4.8Kw. Primary requires 13 turns and must fit through that 57mm remaining hole. We use the on line circles within circles calculator: https://www.engineeringtoolbox.com/smaller-circles-in-larger-circle-d_1849.html And we find that the largest wire that will fit 13 turns through a 57mm hole (or whatever it actually ends up as) will be 13.4mm outside diameter wire. You might be able to find some fine stranded welding cable, or something similar that is 13.4mm max diameter. The figures you finally end up with will almost certainly end up being different to the above. But just follow the general method, adjusting the figures to suit the materials you have. If you plan it all out ahead, it will all work out fine. Edited 2021-08-26 10:04 by Warpspeed Cheers, Tony. |

||||

| teapot Newbie Joined: 22/08/2021 Location: United KingdomPosts: 22 |

Doh! Unfortunately I had already wound the secondary yesterday before I saw the above message! I wound it for 210 turns of 2.0mm dia enamelled wire, spread over three layers (continuous i.e. series, not multiple layers of 210x thin wire in parallel as described in your example), with each layer being separated by glass-fibre tape to minimise the risk of shorted windings between layers should the enamel coating be damaged by rubbing or other mechanical stress. I hope this will work else I have made an almighty c0ckup! I'm wont to run the unit at maximum load (3.6kW) for more than a few minutes at a time (and have a 16A RCBO on the output anyway), so 2.0mm (3.1mm2) secondary should be fine. Any load lasting more than 5 minutes will be under 2.5kW. I wasn't concerned about adjacent turns on the same layer rubbing and shorting as at ~0.6 turns per volt, one shorted turn is insignificant in the real scheme of things, so I wound them as close together as I could to minimise the number of layers. I haven't yet measured the new inner hole diameter, but I will do when I start winding the primary after work this evening. It looks to be somewhere around 50mm though due to the thickness of the tape which is heavily overlapped in the centre area. Assuming an absolute maximum of 16A at 240V AC, and efficiency of 85%, I expect a maximum average current of about 180A in the primary at 24V. Therefore I'm going to wind the primary with 12 turns of either 1x 35mm2 semi-flexible cable or 2x 16mm2 depending on what fits and lays best through the centre. I will then tweak the primary turns and/or CSA after testing until I am happy with the performance under various loads. I will of course power up the PJ with both the old transformer still connected, and the new transformer AC side disconnected, plus LV side current-limited by a large metal-clad resistor and use my scope to make sure that the voltage is in the right ballpark and I get the AC phase the correct way around before I disconnect the old PJ toroid and connect up the new transformer. This should minimise the chance of accidentally letting the magic smoke out of the PJ boards! Edited 2021-08-26 23:19 by teapot |

||||

| teapot Newbie Joined: 22/08/2021 Location: United KingdomPosts: 22 |

With a secondary consisting of 210 turns of 2mm diameter enamelled copper wire over 3 layers, each separated with a layer of glass fibre tape:  I only managed to wind 11 turns of 2x 16mm2 semi-flexible cable for the primary. Was aiming for 12 turns. Will test tomorrow evening and see what happens:  |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

One single winding of 2mm wire will be 3.14mm sq as you say. At 4 amps per mm sq that will be about a 12.5 amp secondary rating. Say 3Kw. Primary wires size of 2x16mm sq will give a primary rating of 128 amps. 128 amps x 24v = 3 Kw. This will run fine all day at 3Kw, and will easily do multiples of 3Kw for short bursts. Eleven turns will be good as well. It just means the peak current through the mosfets and primary will be a few percent higher, but in the great scheme of things that does not matter. It may even be better, as it will allow for a lower final minimum battery voltage, especially as you are interested in achieving fairly high final ac output voltage. This is going to work wonderfully well for you. Well done ! Try connecting the secondary to the 240v grid, and measure the current, that will tell you the transformer no load idling power. This is a bit of a lucky dip, and depends mostly on the quality of the steel alloy used in the core, and its subsequent heat treatment. But it will be an interesting number to know all the same. Cheers, Tony. |

||||

| phil99 Guru Joined: 11/02/2018 Location: AustraliaPosts: 2135 |

A cautionary note. Even a single shorted turn will dramatically increase losses and eventually cook the transformer. It is a short circuited secondary and the current circulating in it will be very high. That said the wire enamel is quite tough so damage during winding is rare. If you are concerned about vibration during operation wearing through the enamel give each layer a coat of varnish to lock the turns in place. Keeping the wire taut during winding usually prevents later movement without varnish. For thin insulation between layers I have used oven bags cut into strips a few cm wide. It can survive 150 C. |

||||

| teapot Newbie Joined: 22/08/2021 Location: United KingdomPosts: 22 |

Yep I'm not expecting any loads to exceed 3kW so as you say my choice of wires for both primary and secondary should be fine. In reality the largest load which will run for more than a few minutes is the washing machine which draws about 2.5kW whilst it is heating the water. My wife has learned to be careful about using multiple high-current devices at the same time so there is unlikely to be any over-current mishaps. Thanks for the reassuring comment about only having 11 primary turns instead of 12. My choice of 12 was based on an assumption of allowing a minimum of 20V at the transformer input. I chose this on the basis that I never allow the battery voltage to drop below 23.2V (the charge controller switches off the inverter via a relay if this threshold is reached and a contactor reverts the fed circuits to grid power), giving a generous 3.2V allowance for voltage drop in cable, boards and components. Having 11 turns effectively means the input to the transformer can drop to 18V before any clipping of the output sine wave occurs (I know that transformer efficiency will reduce with temperature and load, so actually 11 turns might prove to be optimal in reality!). My only concern about having less primary turns was an increase in idle current. But again I can only verify this by testing as has been stated. Regarding the comment about shorted turns, you are right I hadn't appreciated the severity of a single shorted turn. However I used new heavily enamelled wire, and the inverter sits on a bench in the garage so degradation due to vibration is extremely improbable. I hope to do all the tests tonight or tomorrow so will update you then :). |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

Idle current should not be effected by the turns ratio. The PWM duty cycle will adjust the output voltage, and essentially watts loss in the core will be a constant that does not change. I cannot recall anyone here ever having a transformer fail from a shorted turn, but its certainly possible. This has all turned out extremely well. A perfect balance of equal primary and secondary current densities and losses, and I expect it should run pretty much stone cold most of the time. Cheers, Tony. |

||||

| teapot Newbie Joined: 22/08/2021 Location: United KingdomPosts: 22 |

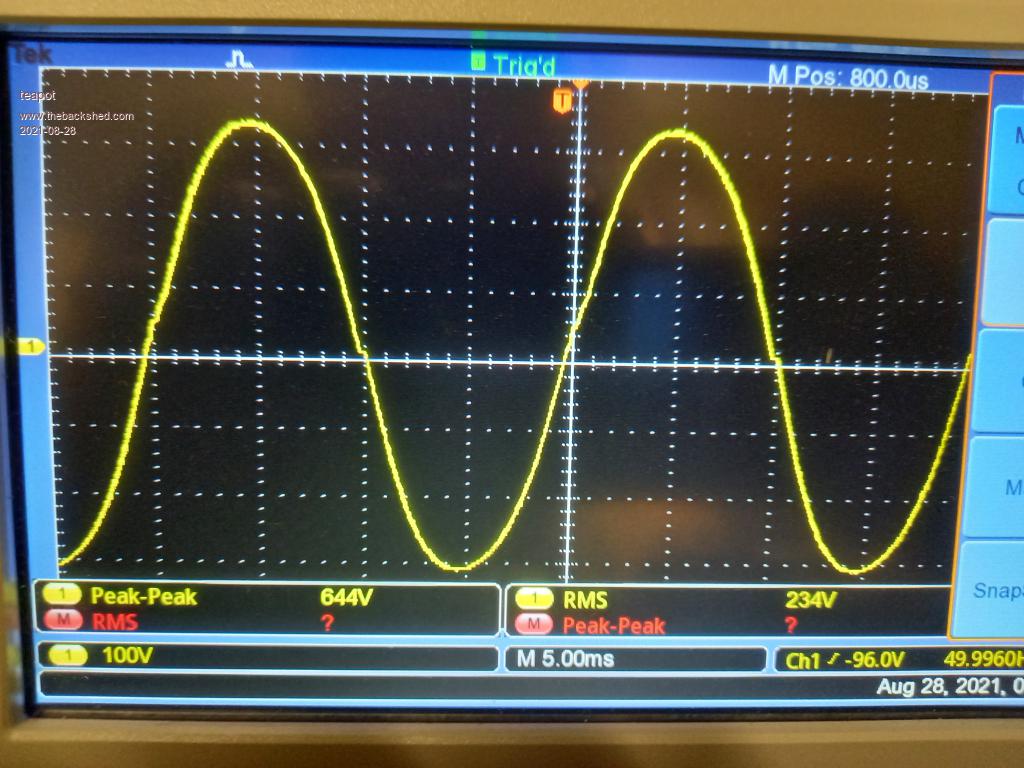

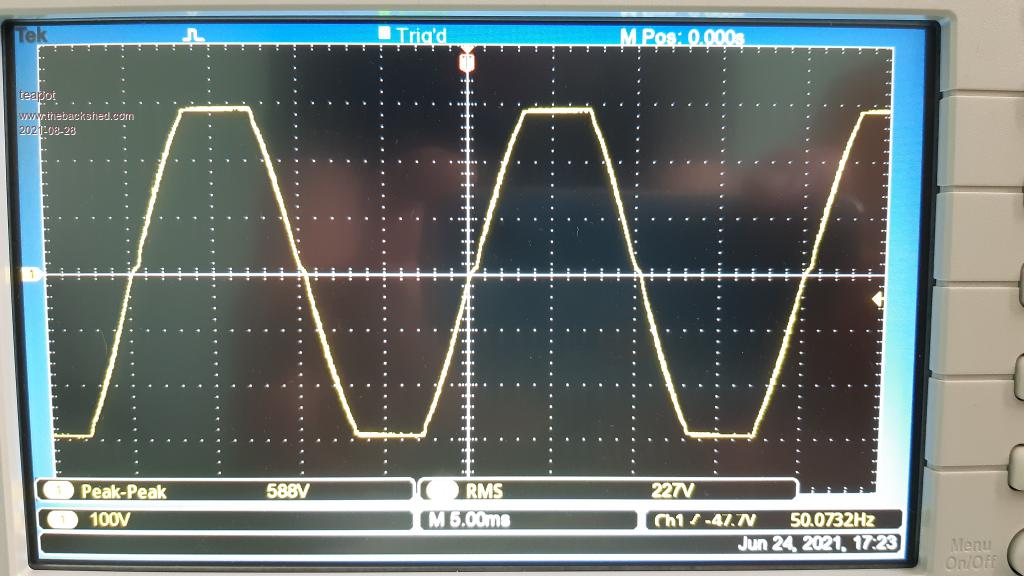

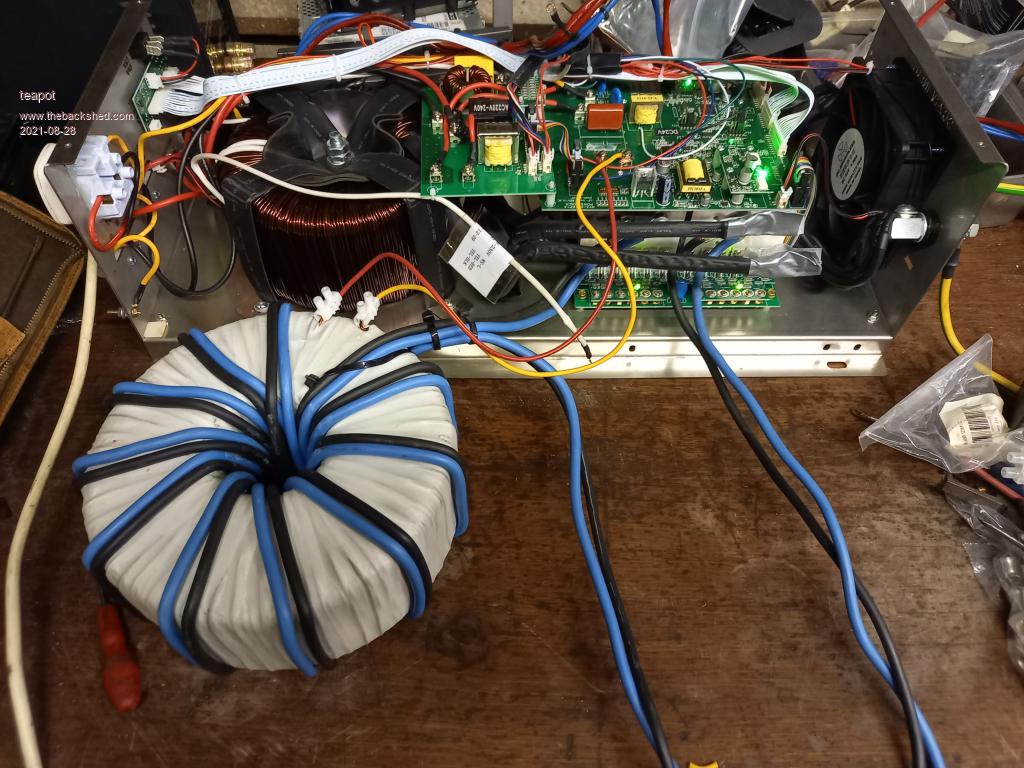

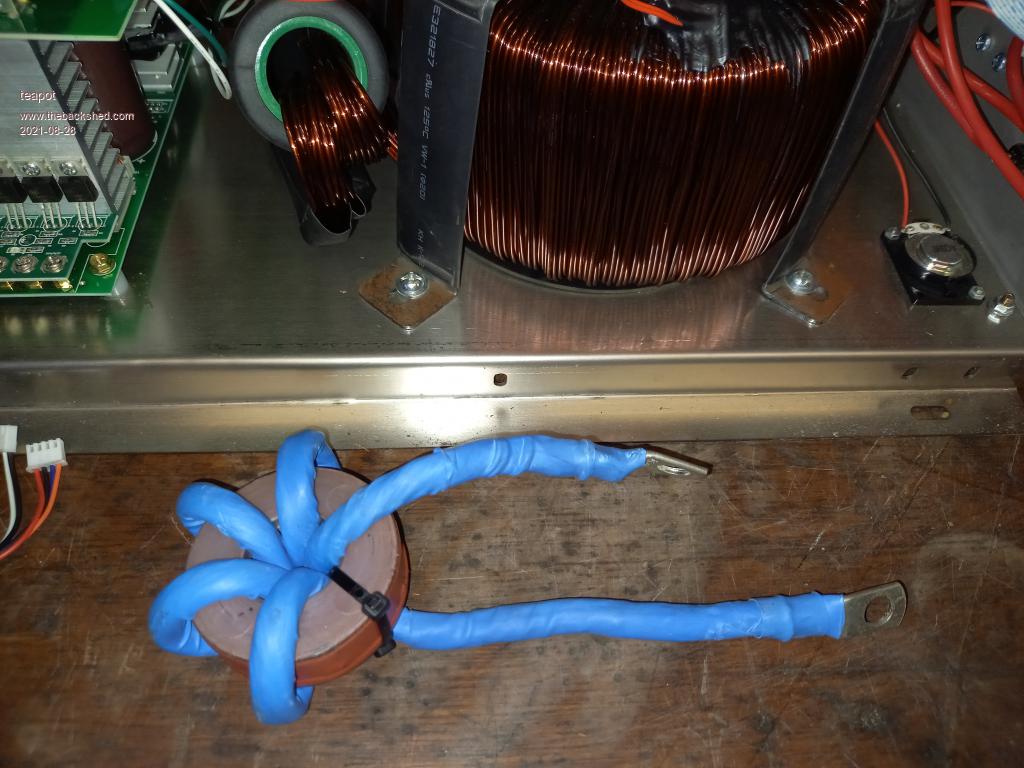

Well good news :) Tonight's test was successful! I couldn't work out which way to connect up the secondary wires to the PJ control board L/N terminals, so I took a chance, and powered it up using a bench PSU limited to 30A, to minimise the size of the fume event if I got it wrong! Thankfully it powered up and behaved as expected. I don't know if it actually matters which way the two secondary outputs are connected to the control board, but thankfully if it does, I got it the right way around! I did an extreme test - 3kW load with long undersized leads from my battery bank, which resulted in only 22.8V at the input to the inverter. Despite this, the output waveform was still near perfect as seen below. I have not done the resistor ladder mod yet, so it is still only about 230V.  It is a huge improvement over the severely clipped waveform seen here with a 2.5 kW load on PJ's own transformer:  I ran this for about 15 mins. The primary windings became very warm due to the high primary current. So some cooling will be required. But the core itself remained cool. Here is a photo of the bodge-up on my workbench:  However the downside is that my DC idle current is now up from 0.6A with the PJ transformer to now 2.5A. Which is as bad as my old 2013 PJ 8k. I also noted that there seems to be a 0.3A AC current on the secondary outputs even when no load. This is the same with my transformer or the PJ. I'm not sure why this is, as I would expect the DC input current to reflect this in the same way. It seems a bit mystic to me.  I don't know what PJ have done to get the idle current so low, as the only inductor on the primary is this tiddly little toroid with one turn. I made my own toroid inductor with more turns to try to reduce the idle current on the old 2013 PJ as can be seen in the foreground of this photo. Although it did halve the idle current, the core got very hot and made some severe deformations to the sine wave output, so I have not used it since and tolerated the high idle current on my old 2013 PJ.  I wish I could find a way to get the idle current back down to < 1A even with my new transformer, then I would have the perfect inverter for my needs. Edited 2021-08-28 05:51 by teapot |

||||

| wiseguy Guru Joined: 21/06/2018 Location: AustraliaPosts: 1156 |

There is a load on the secondary, usually a filter capacitor & because they use a small iron core transformer for the voltage sense circuitry. One has Xc reactance the other Xl and unfortunately unlikely to cancel each other..... There can be quite a phase shift between the voltage and the current so yes there may appear to be 300mA of circulating current but the peak current is a fair way from the peak voltage so the true true power is much smaller. You need to monitor the current against voltage in real time to determine the true power or use a true power meter if you have access to a sensitive one. I can't see a primary choke in your picture when you connected it to the inverter, it is important to have one, but don't use a high grade ferrite unless it has a good sized gap. A Powdered iron toroid or an iron cored inductor which you will find reference to elsewhere here is a must to reduce idling power. Using too many turns may ensure saturation occurs (depending on the core material - iron or iron powder is better) which can heat the core rapidly (and distort the AC output). Best to make up a saturation tester to assist in the choke design. If you used the clamp meter on its AC setting to measure the primary current to calculate transformer input power this is also very misleading, to measure the true power into the inverter use the meter in DC current mode on the cable connecting the inverter to the battery. An inverter can have high circulating currents in the primary yet be drawing a much smaller overall DC current. Lastly, when measuring the toroidal secondary current whilst connected to mains to determine idling power of the toroid, the current by itself is quite misleading. My Toroid was using ~10.5 watts of power going by separate true rms I & V readings but the true power was only around ~6W using an accurate watt meter - around 60% difference ! Edited 2021-08-28 08:20 by wiseguy If at first you dont succeed, I suggest you avoid sky diving.... Cheers Mike |

||||

| Page 1 of 3 |

|||||