nickskethisniks

Guru

Joined: 17/10/2017

Location: BelgiumPosts: 458 |

| Posted: 09:48am 26 Feb 2021 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Hi all,

I need advice on battery packs.

Situation, I have about 3200 lifepo4 of the newer (orange color) 18650 type of valance cells to recombine as battery packs. They all measure ranging from 1250 to 1400mAh each, each are capacity tested.

I also own the older (blueish color) out of 2006 batteries, ready for another 5 to 6 packs, more then 1600 cells capacity tested, they are from 700-1300mAh. I know maybe not worth the effort. But they still hold charge for more then 2 years. I ruined a few original battery packs a couple of years ago, I fully charged them and put away for a long time, watching the self dicharge. Then they had a full capacity test. These I want to use for a home battery at my parents, because rules changed in Belgium, we will get 3-4,5ct/kwh for injecting and we will pay about 25ct/kWh for using. So a battery of about 5-6kWh can pay itself when no more then 100eu/kWh is payed, in about 3 years.

The plan there is to use a boost converter to pull up the battery voltage high enough for the solar inverter to accept, a buck converter (hv mppt controller) can first charge the battery before injecting in the solar inverter.

I'm (going) experimenting with their digital meter to extract all their data. Ordered all the bits.

I own 20 (+1 spare) original 12V 100Ah valance xp manufactured in 2006, I really love them, and they are performing verry well, they are top balanced, but some can't be drained to 0% anymore because of the internal capacity mismatch. The badest battery can be drained to 12V, the rest between 10,4 and 11V, that is 2,5V for the lowest cell. Not that there is a lot to get after 3V/cell. I'm verry curious how long (years) they will hold.

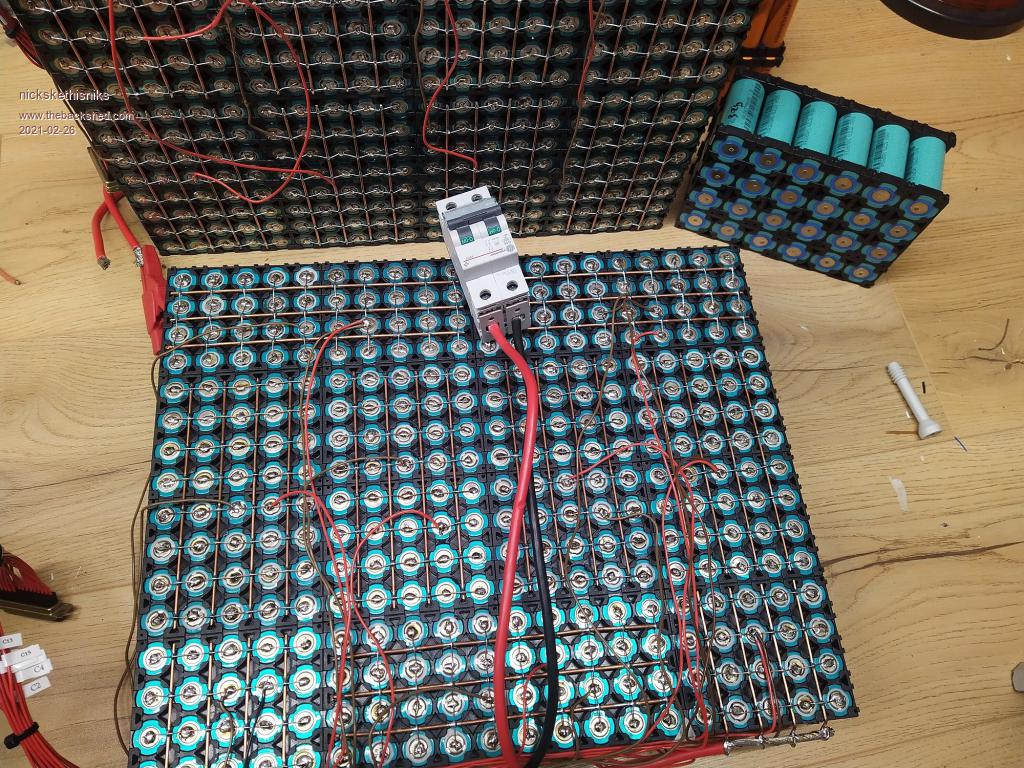

So my original plan was to use 320 cells (20p16s) for a 48V pack, each cell group with a passive top balancer. And this 10 times for the orange and at least 5 for the old ones, maybe I dismantle the worsed battery in my system. Each pack would have a cable with all the balancing cables, for measuring each cell voltage and maybe interconnect to the other packs with maybe some PTC fuses protection. All packs will have a breaker and/or internal fuse.

I think I will still solder the older ones, but a spotwelder is on the list, thinking for going for the Kweld.

I wanted a nice 19 inch case for each battery like the polygon 2,4kWh modules but that won't make this system very cost effective at about 50eu for each battery.

Another option were some second hand metal cases like the one of my ozzinverter is build with. But then I still need several and for the older cells it would not be a benefit to combine the cells. It's like I have 320 cells 700mAh, 320cells 800mAh, 320 cels 900 mAh and.... So then I would be mixing up a lot of different qualities. I don't know at wich point they will actually break internally, I think I read somewhere to get rid of them at 60% original capacity? Some are allready beond that point...

So to keep the price around 10eu/case, I could use some slowing down fire wooden panels like red mdf and for top and bottom Fermacell.

Maybe an old fridge can hold them all togheter and keep temperature constant, or an 19 inch patching server rack.

This is how 2 prototypes are looking at this stage:

What do you think, any suggestions are welcome.

Edited 2021-02-26 20:04 by nickskethisniks |

Revlac

Guru

Joined: 31/12/2016

Location: AustraliaPosts: 1024 |

| Posted: 10:05am 04 Mar 2021 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Hi Nicks,

Looks like a lot of nice work there, I haven't seen many of these in Lifepo4 apart from some of the A123 type, (I let the smoke out of one) but should work ok.

16 nice square bricks of 24 cells, I looked at all this a few times to be sure, the 3 wire bus bars joining each brick together should handle the power quite well, are they 2 or 3mm copper rod?

Doing it this way looks like it might be a lot to look after and keep balanced, but with all those balances it may well take care of it self,

I have noticed and others have said that lifepo4 cells tend to runaway when they get close to full charge or there about's, Where as the Lion type are not so fast or drastic around full charge, so the charge controller settings would have to be very strict.

I would have made them as parallel groups, would require less but bigger balance's, however the setup you have looks like it will perform better with that many separate balances, and you could also disconnect 1 brick (for service) while keeping the rest in place working.

looking forward to see how it performs

great work once again.

Cheers Aaron

Off The Grid |

nickskethisniks

Guru

Joined: 17/10/2017

Location: BelgiumPosts: 458 |

| Posted: 01:19pm 04 Mar 2021 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Hi, since these are old cells I want to use them for some long, low power, probably constant loads max 4-5A for the pack, about 1/5 C. So I used 2.5mm^2 and 4mm^2 wire, that's 10 to 12 mm^2 combined, so a bit overkill but this wires are leftovers from my home electricity.

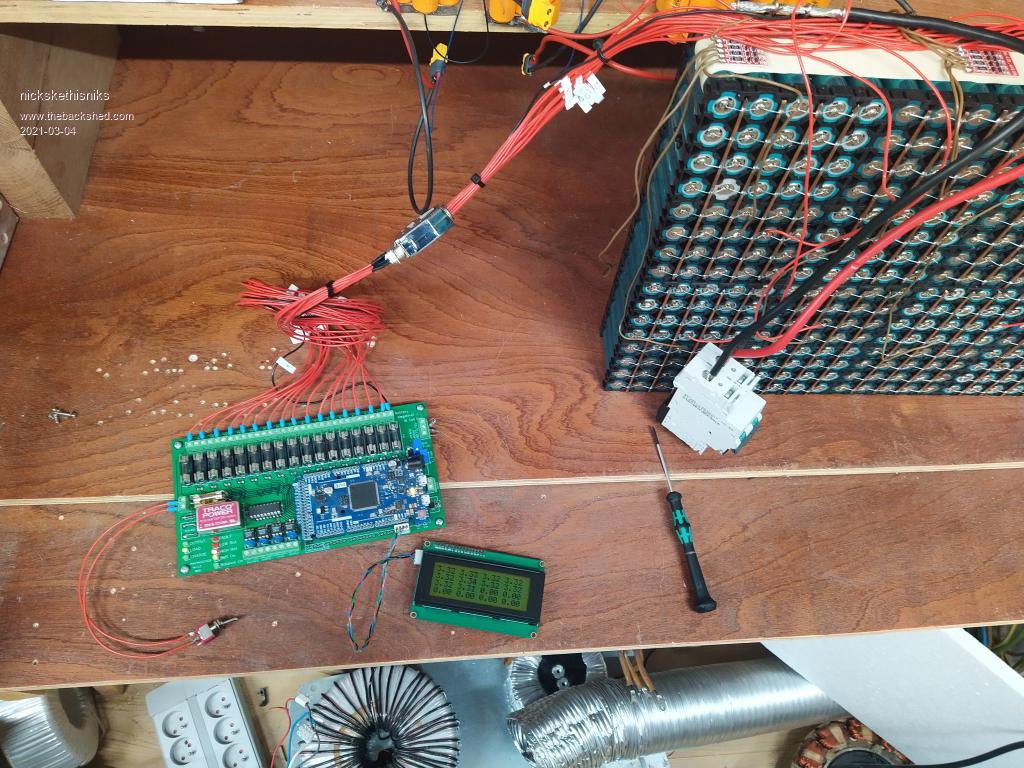

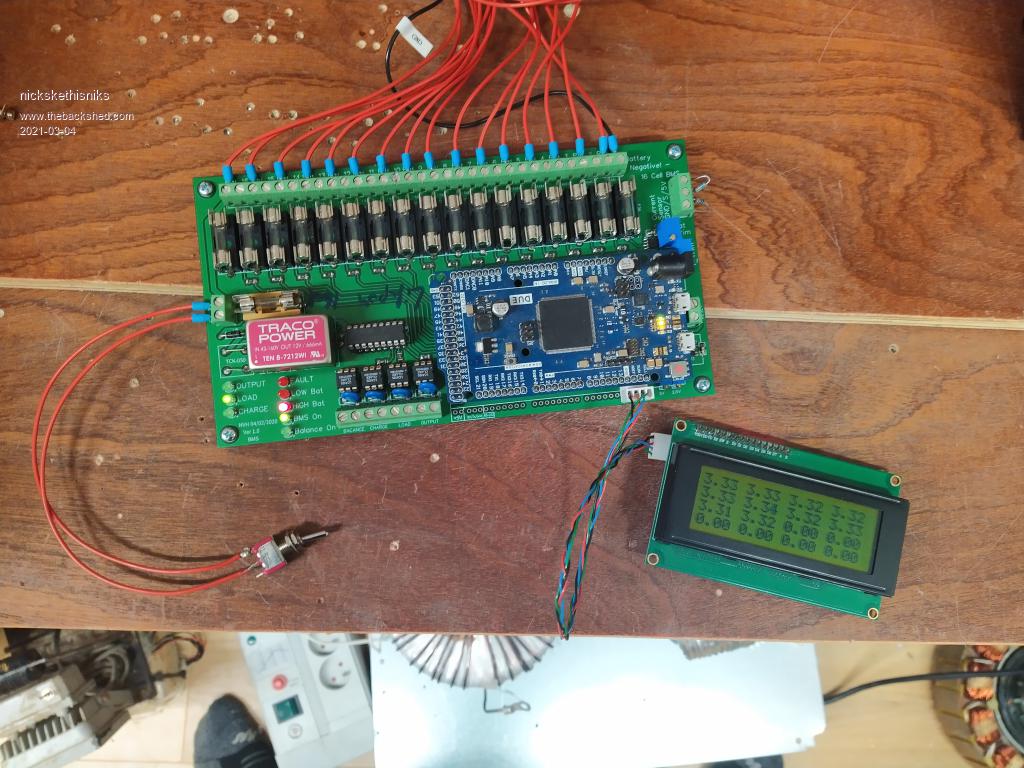

I did solder some extra measuring wires connected to a db25 connector, this way I can read the voltages of the parallel bricks. And maybe add some temperature sensors.

I did design a "universal" bms, this one is loaded with firmeware for a 10cell lto battery. Changing the dcdc makes it suitable for each battery with 4 to 16 cells.

Yes, the downside doing 48v bricks is, it makes the bms part more complicated.

The plan was to connect each measuring db25 connector parallel but with a PTC/fuse in series.

But it got me thinking to build a smaller "budget" bms to add to each pack and do communication with a central isolated uC.

I don't know yet.

Edited 2021-03-04 23:33 by nickskethisniks |