|

|

Forum Index : Electronics : DC Generator project

| Page 1 of 2 |

|||||

| Author | Message | ||||

| arthur8 Regular Member Joined: 08/05/2019 Location: BrazilPosts: 69 |

Hi friends. Sorry if this is the wrong place to post this. Didn't found any place to post about generators. I was looking to make myself a small generator to feed my solar system when the climate is rainy, wich is common on where i live. Since i plan to move to our farm on the future, it is very expensive to have energy from the grid so we will be using our solar system with this generator. It needed to be very robust, to work days and days without interruption in case of some failure on the solar system or anything goes bad by any reason. I was planning to use some Diesel Yanmar or Deutz (love those, but hard to find) motor running a big DC generator. The problem is to find a DC generator with at least 3kW @ 60V is almost impossible. So, with a lot of luck i've found this for dirt cheap and bought it:  The generator is made by Bambozzi (fantastic quality, made in Brazil) and weights 316 Kg and does something about 175A @ 90V DC.  The voltage output seems to be adjustable by an adjustable resistor connected to the generator exciter, also it can be adjustable by the RPM of the motor. It does feature a 1200cc VW industrial engine. Those motors can run almost forever with very little maintenance (oil changes). This engine have been retired decades ago and it almost brand new. I think it have no more than 200 hours on it. My plan is to run this bad boy to feed up (with DC) our battery bank, wich will be connected to my ozinverter. My current plans with this are: --> Install an Arduino to monitor those: - The output voltage (in DC); - Output current in Amps; - current RPM using a hall sensor; - current oil pressure; - current oil temperature; - engine block temperature; - since it is a boxer, individual cilinder temperature (one temp sensor per cylinder head), that way i can find any failed cylinder; - Electric fans control (i plan to close the chassis and use some heavy duty fans to help cooling down the engine). --> Arduino will also control ... - ... the RPM using a small servo motor, this servo motor will adjust the acceleration of the motor, controlling also the output voltage. The generator can work with 20v to 90v by just adjusting the RPM and the variable resistor on the generator exciter. - ... the startup and shutdown of the motor, it will need some control on engine choke valve also. I need to implement an eletronic startup on it, it will be easy using an arduino. - ... some security features, like turn off the engine if the temperature is very high or oil pressure is too low, oil change alarms, etc. For arduino and engine starter, i will use a small 30W solar panel and a 5A MPPT controller that will fed a small 12v capacitor bank (350F maxwell capacitors) and some lithium batteries. The system will be automatically turned on weekly, that way the engine can work fine for a long term basis. Diesel/Gasoline engines don't like to sit for much time without being turned on. I will be buying a GLP kit to convert the engine to run using GLP propane gas, connected by a p45 propane cylinder. Still don't know a way to monitor how much gas is left on the cylinder. Anyone have suggestions on this? The last owner painted the engine and i don't know yet how to remove this paint from the engine. Anyone have suggestions for this also? If anyone have some suggestion or any ideas, please let me know.  Edited 2019-11-19 06:22 by arthur8 |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

That sounds like a welding generator, which should make a very robust and reliable power source. Its an excellent idea and something I don't think anyone else among the off grid mob has ever thought of doing. Top marks for originality ! Throttle (voltage) control could be done with a low cost radio control model servo. These require a continuous pulse train at around 50Hz, and the on time (logic high) between around 1mS to 1.5mS controls the position of the output arm. Perfect for use with a microcontroller. How much gas is left in a cylinder is easy. Sit the cylinder on some bathroom scales. The cylinder will have stamped on it the weight empty, and the weight when full. If you want some kind of warning when the gas gets low, a mechanical scale could be pretty easily adapted to do that.  Edited 2019-11-19 06:58 by Warpspeed Cheers, Tony. |

||||

| arthur8 Regular Member Joined: 08/05/2019 Location: BrazilPosts: 69 |

Hi Warp. Yes, it is an old welding generator made by Bambozzi on the 70's, looks like. From what the seller told me, it was used by our army. Since it is very rainy now, i can't get outside and take more photos, but when we got a sunny day will take more photos. Any suggestion of features to be added, please let me know.  |

||||

| johnmc Senior Member Joined: 21/01/2011 Location: AustraliaPosts: 282 |

Check gas available, by weighing the cylinder . The engine also appears to have a mechanical governor fitted for speed control. cheers john johnmc |

||||

| arthur8 Regular Member Joined: 08/05/2019 Location: BrazilPosts: 69 |

Both very good ideas. I will try with this servo motor (already had it): https://www.ebay.com/itm/MG90S-Metal-Gear-High-Speed-Micro-Servo-Motor-for-RC-Car-Helicopter-Plane/183889883172?ssPageName=STRK%3AMEBIDX%3AIT&_trksid=p2057872.m2749.l2649 The mechanical scale idea is very good, i will try to find any cheap one. |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

I think you have struck pure gold with that welding generator. It will already have electric start and a 14v generator to recharge the starting battery. Its all already there complete, and ready to go. Being ex military, its probably had very little actual usage and will have been very well maintained. Cheers, Tony. |

||||

| arthur8 Regular Member Joined: 08/05/2019 Location: BrazilPosts: 69 |

Hey John. Actually, the mechanical governor (made by Bosch) is removed. It was not working at all. Actually, i will use an simple arduino servo motor to adjust the accelerator. I'm looking at a cheap & reliable way to weight it, and found this: https://www.ebay.com/itm/Weighing-Sensor-100kg-Electronic-Scale-Aluminium-Alloy-Load-Cell-Weight/323902168986?hash=item4b6a12df9a:g:zY0AAOSw5DddbOyc What you guys think? It will be easy to connect this sensor to arduino. But i don't know if this will be precise and last for a good time. But, it just appears to be a small resistance connected to aluminum, looks legit and robust. What do you guys think? |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

That model servo looks pretty much like the one I have, and plan to use on my own generator. They are amazingly fast acting and powerful and very easy to use. I found that it needs some flexibility or a spring in the throttle linkage, otherwise the servo is so powerful it will bend or break something if the amount of travel to the carburetor is not set up absolutely perfectly. Cheers, Tony. |

||||

| arthur8 Regular Member Joined: 08/05/2019 Location: BrazilPosts: 69 |

Thanks, warp. I was very lucky on this one. I hope this topic give ideas to everyone that wants to make a project like this, too. I'm actually waiting some things to came from china to start. I think they should be there only by January.  Starter is working fine and the engine starts easily, too. But looks like the generator is not charging the battery, will need to test it more to understand what is going on. Actually it won't need the generator, since it will have a small 30W solar panel connected to the battery/capacitor bank. But i want to fix the generator, so it will have more redundancy.  |

||||

| arthur8 Regular Member Joined: 08/05/2019 Location: BrazilPosts: 69 |

Thanks for the follow-up, Warp. That's really good news. Was afraid if this thing was slow. And thats a fantastic suggestion. Will use a little spring to avoid the carburetor being destroyed if the servo goes crazy. I plan to monitor the voltage with arduino, and if it detects any voltage drop it need to push fast the throttle to speed the engine up and the voltage gets back to its normal value, independent of the current load. I plan, also, to keep some big bypass relays, so i can weld with it when i want. Also, plan to add a DC output plug, and with arduino + potentiometer, i can configure to have an stable output from 20 to 90V, by just making arduino to speed up or down the throttle. And, maybe, a small ozinverter installed, so i can have 220v output for emergencies. So much features and they won't cost me almost anything, thats the good part.  |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

That e-bay strain gauge sensor will only output a few millivolts, its going to require a strain gauge amplifier to amplify up that signal up to something usable with an Arduino. Another way to do it would be to hang the cylinder from a digital spring scale.  Cheers, Tony. |

||||

renewableMark Guru Joined: 09/12/2017 Location: AustraliaPosts: 1678 |

Awesome rig!!! Hell yeah, I'm jealous. Caveman method to tell the LP level, pour hot water down the side of the tank, then put your hand on the tank and feel for the cold spot, it will be really obvious. Once again, it's caveman style, not scientific, but it works. Cheers Caveman Mark Off grid eastern Melb |

||||

| BenandAmber Guru Joined: 16/02/2019 Location: United StatesPosts: 961 |

That is exactly what someone off grid needs That was smart thinking and a good find Hope you dont mind me stilling your idea I am definitely keeping my eye out for old gasoline or diesel welders I have seen a few here and there just didn't put one and one together Just awesome be warned i am good parrot but Dumber than a box of rocks |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

Just the bare welding generators sometimes turn up, either because the engine originally driving it was unrepairable, or the welding generator may have previously been used as an accessory on the power takeoff of a tractor. Auctions and machinery graveyards might be worth checking out. Cheers, Tony. |

||||

| SimpleSafeName Guru Joined: 28/07/2019 Location: United StatesPosts: 319 |

I took one look at it and said "That's a VW engine!" :) Nice find! A scale would work just fine for detecting a low cylinder. And I don't know if this applies to a gas generator (I imagine that it does), but they don't like to be run empty. You want to shut down your load and let the engine run for 15 minutes or so to cool down the genny. |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

The thing about a welding generator is they are always rated for intermittent operation. Nobody welds continuously, so the rating plate might say something like 150 amps 60% duty cycle. Should be no real problem running something like that continuously at 80 to 90 amps to charge a battery. Cheers, Tony. |

||||

| arthur8 Regular Member Joined: 08/05/2019 Location: BrazilPosts: 69 |

Hey Bernard, I'm glad to know this will help someone.  |

||||

| arthur8 Regular Member Joined: 08/05/2019 Location: BrazilPosts: 69 |

You are right. Was not sure about this value. The label on the generator says "Bambozzi 375". When looking for the 375 model, i've found this: http://www.bambozzi.com.br/website/soldas/produtos.php?produto=365 This page says this bad boy is capable to just not 150A, but 375A. The soldering cycle on those is 375@60% That means, 375 Amps per each 6 minutes. It should rest for cool down for 4 minutes and then it's ready for another 6 minutes of 375A. I think the 150A rating is for continuous usage. Impressive. That makes sense, the welding generator needs 30HP to run and the vw engine provides 32HP. Thats very good ratings. Will never use more than 100A anyway.  |

||||

| arthur8 Regular Member Joined: 08/05/2019 Location: BrazilPosts: 69 |

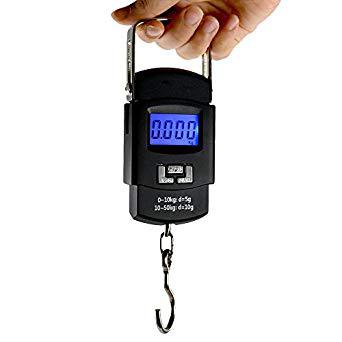

That's bad. Still don't know a cheap & reliable way to import the Kg value on Arduino. Maybe this?  I can put a small sensor on the gauge so i can have alarms when the GLP is low. The problem is that i think this things are not made to have this weight 100% of the time and can lost the precision over the time. Still looking, any suggestions, please let me know! You got very good ideas. Edited 2019-11-19 16:26 by arthur8 |

||||

| arthur8 Regular Member Joined: 08/05/2019 Location: BrazilPosts: 69 |

Hey Mark. :-) Sounds like a good idea, i like it and for sure will test this tomorrow. But, i would love to get some alarm when the gas is running low. Bad news is, i can't see any easy way to get the weight info on arduino. Just need some sensor that outputs any analog or digital value, so i can import it on arduino. The ebay sensor i've been looking before looks too complicated for me. Any suggestion on this? |

||||

| Page 1 of 2 |

|||||