|

|

Forum Index : Electronics : Relays: Carbon contact refurbish

| Page 1 of 3 |

|||||

| Author | Message | ||||

Chopperp Guru Joined: 03/01/2018 Location: AustraliaPosts: 1057 |

Hi all I'm working on a couple of old GE voltage / current regulators out of diesel-electric locos. The regulating relays fixed contacts (4 in total) are carbon tipped & most are badly worn (see photo). Does anyone know if they can be refurbished or not? Mr Google or Mr Bing haven't been much help. Thanks.  ChopperP |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

What you want are carbon contacts, not carbon brushes, but the two are sort of related. Many shapes and sizes, many different grades (hardness) of carbon. Remember the old "Scope" soldering irons with a push to heat carbon heating element ? Try Googling carbon brushes... There are many companies that specialize in making replacement carbon brushes for all kinds of motors and generators, and related things such as carbon contacts. I am sure they might either have something suitable, or can make something up for you, or at the very least give you some excellent advise. Cheers, Tony. |

||||

Revlac Guru Joined: 31/12/2016 Location: AustraliaPosts: 1024 |

I used to go to most of the QR Railway Auctions, pick up some goodies at times, last one I went to they had a large box/vat full of used and or unwanted motor & generator brushes and possibly some of those in there as well, all went for scrap. Looks like that brass bolt has a recess turned in and the carbon sits in a little then the brass might be rolled around the top, just enough to grip the carbon insert? I could well be wrong but thats all I could guess. It would have to be good quality carbon too, unlike the stuff they have in cheap power tools. Is there still a Loco sitting under cover at Bell?  I still have an old scope soldering iron, still works.  Cheers Aaron Off The Grid |

||||

Chopperp Guru Joined: 03/01/2018 Location: AustraliaPosts: 1057 |

@ Warpspeed Tony I've got someone looking into it at the moment. Thanks for the suggestion I too have an old Scope which still gets used. Haven't checked the element for ages. Not game  At Revlac. Drilled into the carbon bit. goes down about half way or ~3mm A lot of stuff gets chucked out sometimes.  Is this the one?  Now at DownsSteam @ Drayton, Toowoomba ChopperP |

||||

| johnmc Senior Member Joined: 21/01/2011 Location: AustraliaPosts: 282 |

Have you tried the EDM carbon ,which is a special hardness used for EDM sinking machines It is relatively hard and easily machined, if you cannot get some locally I think there is still some round bar in the shed that you are welcome too. cheers john johnmc |

||||

Chopperp Guru Joined: 03/01/2018 Location: AustraliaPosts: 1057 |

Hi John, Thanks for that info. Didn't know about this stuff. Found this. At 10mm, it's ~0.5mm bigger than what I want (0.375" or 9.525mm). Cheap enough to try. You mentioned that it was easily machined so I assume it be turned down & cut to length in a lathe? EDM Rod ChopperP |

||||

| johnmc Senior Member Joined: 21/01/2011 Location: AustraliaPosts: 282 |

Yes you can machine with a lathe or a milling machine(beware that it puts carbon dust every where) It is a especially fine grained And a very good conductor, it usually machined the male shape, then a controlled current, sparks the metal away electron by electron to form the female shape for injection molding. cheers john johnmc |

||||

| johnmc Senior Member Joined: 21/01/2011 Location: AustraliaPosts: 282 |

I forgot to say that there a lot of carbon rod about that is soft and not very machinable, I do not now what the chinese carbon is ( it may be alright) but the edm carbon is hard ,so that it maintains it shape john johnmc |

||||

Chopperp Guru Joined: 03/01/2018 Location: AustraliaPosts: 1057 |

Would this stuff be better? A more expensive, longer, but the right diameter. More Rods ChopperP |

||||

| johnmc Senior Member Joined: 21/01/2011 Location: AustraliaPosts: 282 |

I am not sure about the expensive carbon either , years ago, when we some times had to make automotive brushes there was a few grades, with the softer grade used in generators and the harder grades used in starter motor,s ,it depended on the current density. What is the current density and is it continuous contact with a moving surfaces? If the carbon brushes are easy to replace I would try the cheap carbon. Thirty odd years ago there used to be a French company in Melbourne that supplied all types of carbon cannot, remember the name of the company cheers john johnmc |

||||

Revlac Guru Joined: 31/12/2016 Location: AustraliaPosts: 1024 |

@ ChopperP Yes that Loco is looking nice, long time since I was out that way, I see it was moved by a truck. Had a good look over the website, very nice.  And I'm also guilty of building a railway around the yard.  I helped a friend restore a fairmont railcar some time ago, I always like this railway gear.  Had some carbon skids used on Trams i think. Cheers Aaron Off The Grid |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

I suppose it depends on your purpose. A genuine restoration probably should have the correct original carbon contacts, but its pretty old technology. Carbon used to be used for high voltage ac switching, but the more modern contact material for high voltage ac switching are solid tungsten contacts. If its DC being switched, which is very unlikely in this case, solid silver contacts would be the more usual contact material. Cheers, Tony. |

||||

Chopperp Guru Joined: 03/01/2018 Location: AustraliaPosts: 1057 |

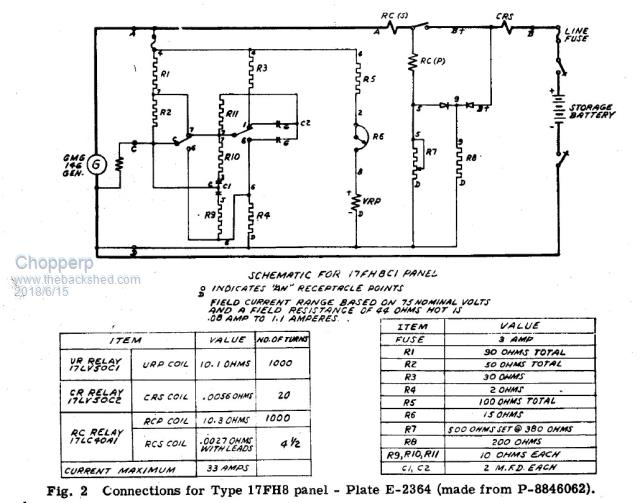

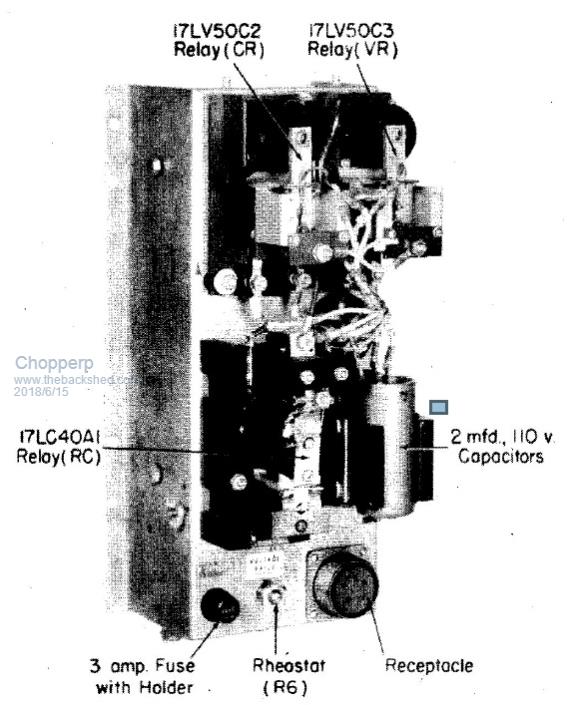

John, Circuit & unit image below. Hope it is clear enough.  The current relay CR, is on the far left of the circuit & VR, the voltage relay is on it's right. (The cutout is at the top). There are some suppression capacitors with series resistors across the contacts which make the drawing even more confusing (for me anyway). There's only about 0.5 - 1.3A switched on & off through the field coil by the relays when regulating but it operates at about 70V which can cause a bit of arcing if not set up correctly. The relays are quite finely balanced when limiting. The contacts themselves are a pain in the butt to replace & setting the unit back up again is even worse. (Require 70V+ for the volts & 33A+ for the current). The Loco is for a Heritage railway, so will not be in continuous operation so the cheaper ones may do for the time being. Regards Brian   ChopperP |

||||

Chopperp Guru Joined: 03/01/2018 Location: AustraliaPosts: 1057 |

@Warpspeed. Spend ages trying to formulate a rely to John. Not ignoring you. It does switch DC as mentioned above & can switch quite rapidly. Yes, it is very old technology. I have designed & built a solid state version but further in situ testing is required for this. We will have 2 Locos shortly, so need at least one really good unit, even if for a spare. @Revlac Glad you liked the Loco. Still work to be done on it. There is a fair bit to see out at DownsSteam. Was it a Section Car you helped restore? We have a few members who are also keen on this sort of thing. A railway around the yard? Interesting. I have never really been interested in trains & didn't know DownsSteam existed until Jan last year when I was asked to look at an electronics job for the Loco by a mutual friend. Been in Toowoomba 25 years. Been helping out ever since & slowly learning about the in & outs of railways etc. I ramble  Regards Brian Edit: info on 1172 Loco Disposed by QR 1989 Transferred to Mt Morgan Shire 1991 Sold to Wambo Shire/Western Downs (Bell) 1998 Loaned to Downssteam 2010-now. ChopperP |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

I am not a train nut either, but I did work at Westinghouse Brake and Signal for several years in R&D so have a very vague idea about Locomotives and those terrifyingly large high voltage locomotive batteries. If its dc and the replacement carbon contacts don't work out for you, solid silver contacts are the go for heavy dc applications. Silver has excellent thermal and electrical conductivity and is the recommended material for heavy duty direct current switching. Many years ago I bought some silver bullion bars from a company called SBA Amalgamated. They reprocess and refine silver scrap and produce all kinds of silver products, silver wire, silver rods, silver sheets, silver foils, and more importantly solid silver electrical contacts. E-mail address is sba@sbaamal.com.au They are located in Bayswater Victoria. Cheers, Tony. |

||||

Chopperp Guru Joined: 03/01/2018 Location: AustraliaPosts: 1057 |

Thanks Warpspeed. Yes, got to be careful with them batteries  . . The only real heavy switching is with the cut-out & that is just one-off event & that has solid contacts. Cost is a factor in whet we do here. The cheaper the better. Will check out the silver ones though. Off to play trains Brian ChopperP |

||||

bigmik Guru Joined: 20/06/2011 Location: AustraliaPosts: 2914 |

GDay Chopper, It looks to me like you need 3/8" Dia Graphite rod.. is 10mm too big in practice? The way I would go about replacing those is to use a lathe and bore into the head of the Brass screw a few mm.. The bore needs to be probably about 1-2 thou (0.001-0.002") smaller in dia than the carbon rod.. Heat the screw up in an oven (Or blow torch) the rod should be able to be pressed home and when the screw cools down the rod should be held fast without glue etc.. Just machine the face to size and resurface smooth (I have never machined graphite rod so I am not sure of the best methods here). You would then end up with nice `original' looking replacement contactors.. It has been 33 years since my `toolmaker days' but that seems a pretty simple task for a machine shop to perform. Tell them you are a hobbyist restoring historic trains and they might do a cheap cash job for you. I assume the carbon was to prevent pitting of the contacts..? Kind Regards, Mick Mick's uMite Stuff can be found >>> HERE (Kindly hosted by Dontronics) <<< |

||||

bigmik Guru Joined: 20/06/2011 Location: AustraliaPosts: 2914 |

Hi Chopper, This Company advertise small sizes and qty for Hobbyist.. It might be worth giving them a call Kind Regards, Mick Mick's uMite Stuff can be found >>> HERE (Kindly hosted by Dontronics) <<< |

||||

Chopperp Guru Joined: 03/01/2018 Location: AustraliaPosts: 1057 |

Hi Bigmik, I measured the existing contact at 0.375" (3/8"). I think it goes into the bolt head about 3mm. 10mm is only about 0.5mm bigger. The idea of heating it up is a good one. I don't particularly want to experiment with one that still has a bit of life in it but I will have to. I think carbon is used because the contacts can be switching quite rapidly and the actual contact force can be quite low. The alloy armature contact faces still pit quite a bit. I found that company yesterday while searching. Didn't look too "friendly" to me so I didn't look very hard but I will have another look. We do have a lathe so machining shouldn't be a problem. Thanks for the comments. Brian ChopperP |

||||

| johnmc Senior Member Joined: 21/01/2011 Location: AustraliaPosts: 282 |

The carbon to bolt head attachment in your initial picture , looks to me that it has been rolled over the carbon , which is easy to do with a roller wheel instead off a tool. maybe the bolt end of the carbon has a step a little larger to roll the metal over the carbon end. just a idea john johnmc |

||||

| Page 1 of 3 |

|||||