|

|

Forum Index : Electronics : Building an inverter - toroid help...

| Author | Message | ||||

Grogster Admin Group Joined: 31/12/2012 Location: New ZealandPosts: 9308 |

Hi everyone.

There are a few threads hovering around the forums now, on re-winding inverter toroids to make a really juicy tranny for a home-bake inverter that really CAN deliver the 230v current - unlike many of the units found on eBay etc. I am probably going to use the module that oztules linked to in another thread - this module here.(the 48v/6kVa version) and a suitable custom wound toroid. Therefore, the battery bank will be a nominal 48v, so I need help or pointers as to the dimensions of the toroid I should be going for, and the number of windings on the primary and secondary, plus the guage of the windings. I seem to recall reading in the other threads of those who re-wound old inverters, that they tended to wind the secondary out of three-in-hand 2mm copper, and so that is probably the way I would also be doing it, unless someone thought that perhaps four-in-hand would be a better idea. The other gauge I saw being talked about was 1.6mm three-in-hand I think it was. The tranny would need to be able to deliver 6kW under full load without overheating, and I always prefer a little bit of over-engineering such that by sucking out 6kW, the tranny is not running at 100% capacity, but more like 80% or so. This way, the tranny should never ever overheat or burn out in an ideal world - even at full load, as there is a safety margin there in terms of the capacity of the tranny if you see what I am trying to say...... oztules seems to be our resident inverter guru, so I would love his input at this point, along with anyone else who has "Rolled their own". I don't suppose there are some formulas or something that can be used to calculate the required tranny size, winding wire gauge and turns is there? Then I could just plonk in the figures, and the formula will tell me what I need to build. Thanks for any replies. Smoke makes things work. When the smoke gets out, it stops! |

||||

| yahoo2 Guru Joined: 05/04/2011 Location: AustraliaPosts: 1166 |

hi grogster, it is going to depend what you can find. the base toroid in oz was 1.5kw inspire or cehe or a 1.5 or 2.5 aerosharp. there were several different versions of transformer in each brand so you are not going to know exactly how you will rewind it until you get one in your hands and test it. there is also a few overkill versions with a stacked pair. most of the inverters were recalled units that were auctioned in bulk and later turned up on ebay, etc. I guess you have read tinkers thread, what about oztules cleaned up transformer winding thread in his user journal? http://www.anotherpower.com/board/index.php/topic,1044.0.html some of the older threads are long and hard to decipher, there is a lot of shorthand talk, mostly because we have been banging on about this for 4 years now. I'm confused, no wait... maybe I'm not... |

||||

Grogster Admin Group Joined: 31/12/2012 Location: New ZealandPosts: 9308 |

Thanks, yahoo2, yeah, that was also my problem - several threads spanning several years and it all starts to become quite confusing as to which ended up being the best method etc, etc, etc...... I will see what I can find here for the toroid, and post back once I have something, and perhaps then the gurus can give me some winding hints.  There is also the option of getting a toroid professionally wound at a transformer factory. This is not horribly expensive considering the size and weight of the beast, but it will set you back the best part of a grand in New Zealand dollars. There is also the option of getting a toroid professionally wound at a transformer factory. This is not horribly expensive considering the size and weight of the beast, but it will set you back the best part of a grand in New Zealand dollars.

But simply not having to unwind and rewind bloody toroids is pretty much enough incentive for me to spend the cash and have a tranny factory wind up exactly what you want. Many of you will not agree with that I expect, as this is a very expensive way to get your toroid compared to "Rolling your own". The trade-off is much less stress!  Smoke makes things work. When the smoke gets out, it stops! |

||||

| Clockmanfr Guru Joined: 23/10/2015 Location: FrancePosts: 429 |

Hi Grogster, I have just posted elsewhere on this. I have been running a 6kW OzInverter from September of last year, it hasn't missed a beat, and does not get hot. It even sits in a covered cupboard on an exterior wall, so it got the -20c below and +30c, sun, wind, and rain. Testing of course, not advisable for normal mounting. I love it. Originally I purchased an expensive, what I thought was the Rolls Royce of Inverters, by a well known manufacturer, (I cant tell you who it was, as they have a gagging clause on me now, just so I could get my money back). Well, when it was back charging just a little bit the HZ would go stupidly high and domestic appliances would fail. The manufacturers comment, "Buy all are ancillary equipment to stop this". Basically a lock in. Just Nuts! So with Oztules help I have a Robust, Simple, and very importantly very cost effective World beating 48v dc to 230ac, 50HZ, pure sine wave Inverter. Please remember I have very little electronics abilities, and boy what a steep learning curve that is, but 'oztules' helped in giving a hands on empirical evidence. My 6kW OzInverter, used 2 off stacked toroid cores of 190mm outside diameter, 90mm diameter centre hole and 60mm high, and these two gave us 120mm high core, or a section through the core of 100mm x 120mm. 4off/4 in hand 118 turns of 1.8mm diameter enamelled copper wire as the secondary windings, and 14 turns of 50mm/2 insulated copper cable as the primary winding. For the BigOzInverter No2, I am using 2off cores, 230mm outside diameter, 100mm diameter centre hole and 70mm high. Stacked/joined together, gives us 140mm high core, or a section through the core of 130mm x 140mm. The windings will be, 5off/5 in hand 80 turns of 1.8mm diameter enamelled copper wire as the secondary windings, and 10 turns of 70mm/2 insulated copper cable as the primary winding. When finished, this larger toroid will be about 42kgs/91lbs in weight. For real working data & calculations on the core........ see. http://www.anotherpower.com/board/index.php/topic,1117.0.html?PHPSESSID=h7jd5l4edljl6k4ls18pgfj4i1 I think for clarity it should be remarked that the OzInverter should be seen in the whole.... Get the Toroid right and get everything else right.... Reasons for this design of Toroid. Why don’t we just buy a toroid transformer ready made? Ahh, that’s where this toroid design wins hands down. 1. We double, treble, quadruple stack the cores. Keeps the copper loss down, but increases the core mass so its cooler and can handle more. But, now’s here the sting, the core centre is now too small, because of its double stacked height, for a normal commercial toroid manufacturing winding machine to get in. So this design has to be hand wound. 2. After each secondary winding, we Epoxy the winding before putting the next layer of Mylar insulating tape on. Its not to heavy coating, but this stops the windings from vibrating, rubbing together and eventually failing, it also helps with cooling. 3. As this design is hand wound, the Primary small number of turns can be the full size big diameter cable. This also helps significantly with keeping the toroid cool as this winding is open, and air flow can easily circulate around and through the toroid. Get the Electronics, Control & Power Board right, but this must be thought out......Ease, simplicity, robustness of manufacture........ease of cooling the boards and keeping moisture away, so effective mounting is important. ......Cooling system is important, again Oz's cooling circuit works very well, my 4 fans, and its rare that i see them all on and working flat out. I have come away from PowerJack Boards, because of the Uncertainty of supply and serious QC issues. There is nothing wrong with the PJ 15kW boards, but like me Oz would rather be in total control of the manufacturing process and not beholden to any manufacture...... Again Oz has thought out all the parts for the Boards and that they are readily obtainable. At present my stumbling block is the GERBER files for the Manufacture of the New 6kw-15kW Power board. Individual manufacture as DIY job with Masks is now complete and I will post soon. The E choke is important and this brings down my idle power use to just 45watts, now, for a single winding that's pretty darn good. Internal Cabling, both DC & AC, EMC filters, and RCD for the 230vac output are all important and need to be approached in the correct way. In Conclusion...... Most of my life I have looked at Inverters and wondered. I made a little 200w toroid 30 years ago. But this OzInverter is a life changer, not just for folk like me, but this project gets a real working cheap Inverter out of the clutches of the Corporations and vested interests. And Boy do some not like this concept, yes I get weekly abuse about my Book, even the ISBN number has been with held because of complaints from the so called professionals. The detailed book/manual, 120 colour photos, 76 pages, is about my construction of a 6kW OzInverter, and the Big OzInverter, with chapters for each distinct construction stages. I have also added separate instructions and appropriate comments from ‘Oztules’, who’s jottings, 60,000 words, are open source on the World Wide Renewable Energy Forums … http://www.anotherpower.com/board/index.php …….. http://www.fieldlines.com/index.php , and http://www.thebackshed.com/forum/home.asp When I get the PCB boards back from the manufacturers, just 20, and tested I will put a link up on our site and hopefully, with permission of the Moderators, post a link here. Good luck 'grogster' and enjoy the voyage.... I certainly have........ Everything is possible, just give me time. 3 HughP's 3.7m Wind T's (14 years). 5kW PV on 3 Trackers, (10 yrs). 21kW PV AC coupled SH GTI's. OzInverter created Grid. 1300ah 48v. |

||||

Grogster Admin Group Joined: 31/12/2012 Location: New ZealandPosts: 9308 |

Wow - nice big post - thanks!

Very useful information. Where can I buy a copy of your book? It may prove to be very useful. Perhaps it is better to use the custom-designed circuit that I have seen floating around the forums. I do like the idea that if something goes wrong, you can service and repair it yourself, rather then be stuck if a commercial module dies and you don't have a replacement... I would love opinions on that too, but it is probably a no brainer. I would love more information on the home-bake inverter driver controller thing I have seen around the forums, that use the eBay pure sine-wave driver PCB. Smoke makes things work. When the smoke gets out, it stops! |

||||

| Tinker Guru Joined: 07/11/2007 Location: AustraliaPosts: 1904 |

Hi Grogster, May I suggest you take this project one step at a time rather than worrying yourself about parts you need much later? This inverter building project hinges on acquiring and modifying a suitable toroid transformer. So, concentrate on that first. I used the toroid out of a 3KW AeroSharp inverter and found it very suitable. Look for a toroid that's big and heavy >10kg with a big hole in the center. You'll be taking some or all windings off and replace them with others. Clockman posted some core sizes but you can't measure that until you take off all the windings from an existing toroid transformer. Read my post (tinkers inverter project) or Gizmo's post on his inverter build for getting on the starting block. If you are a person who likes to know more technical info why it was rewound this way and not that way settle back with a cuppa or 3 and read oztule's entire loooong post on the other forums. You'll need a pad & pencil to note down the salient points that appear arbitrarily throughout this post. Its well worth the time and effort, at least it was for me as I like to know why I'm supposed to be doing things that way. Rewinding a toroid transformer takes quite some time and new ideas about the driver/ Cmos power boards may appear here during the time you do your toroid transformer. It may be possible to have one commercially wound, at least the secondary winding, but it may be noisier as they are unlikely to epoxy coat each layer before winding on the next. It will be a lot cheaper to rewind your own. Once you find what appears to be a suitable candidate post some pictures and measurements (mechanical & electrical) here and I'm sure you will be advised as to best proceed. Good luck with your search. Klaus |

||||

Grogster Admin Group Joined: 31/12/2012 Location: New ZealandPosts: 9308 |

Sounds like good advise.

Thanks. I will find myself a transformer first. Smoke makes things work. When the smoke gets out, it stops! |

||||

| Clockmanfr Guru Joined: 23/10/2015 Location: FrancePosts: 429 |

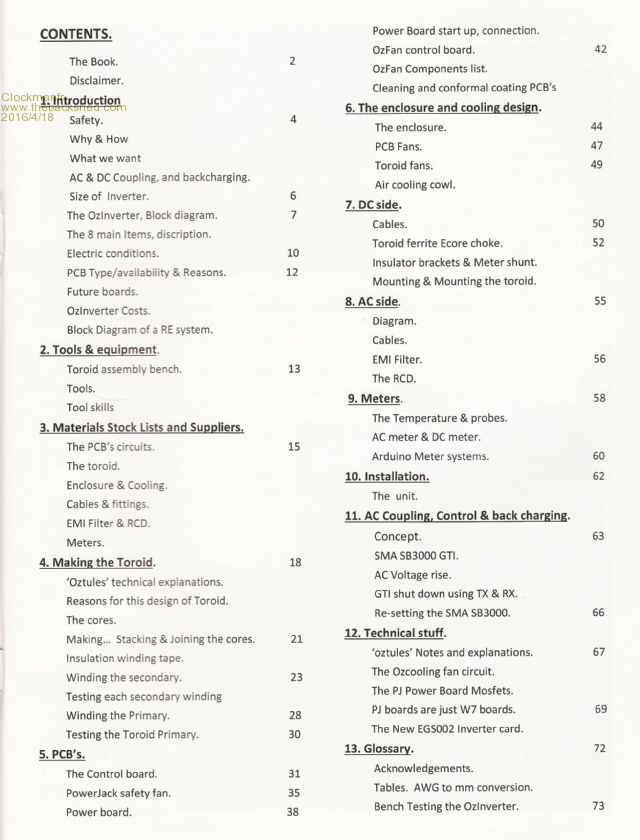

Hi Grogster, Yea I do go on...... The new 6kW-15kW Power board, 282mm x 174mm, 2 oz copper, I have put together is based on the single PCB PJ Power Board but modified with more & different components to match the new OzControl board. ie they are a matching pair. I have beefed up the Power Board in appropriate places, but really tried to keep things simple, robust and cost effective. (So any one on this Planet can put the things together without specialised gear). The book is printed, but I am awaiting the PCB's now so that I can add a addendum pull out. This will contain real size PCB masks, ready printed as a DIY for your own boards. These are slightly different and have no solder stop masks so they can be tinned and small straps soldered on, that's if the person can not readily obtain 2oz copper boards. However it would be real nice to point folk at a supplier of the ready made PCBs, 'Grogster'.??? Electronics is not my World, I do Microengineering, mechanical manipulation, 40mm to 5 micron. But the last 16 years I send the Mrs out to work, she can earn a lot more than me. I raise the 3 boys, and do the small farm here etc, and my Horological Projects. I was, still trying to do 20 boards each, promised 'oz' a couple for his wisdom, but boy the PCB manufacturing process is clunky, against my CAD designs, DXF etc. 'FranknFurter' is helping to get the files to a PCB manufacturer but..... There's a real Art in keeping things Simple, Robust and Cost Effective. PCB Software is Target 3001, about $180 single Commercial use, and can handle my engineering DXF files, a little tweeking in Target and they are Gerber Files. If you are willing to be a supplier of the matching boards, I will send the Gerber files to you. And make what you can from them. The masks have my Bryan MicroEngineering on them, but remove that and put the OzInverter 6kW-15kW PowerBoard, and the OzControl Board. I, we, are a not for profit on renewables stuff so just the printing, Post and Packing. Once the Pcb's are put together and tested, then I will ask 'Gizmo' here on this Forum for some links, and I will add a PayPal link on our web site, a bit like this.......'2kW PV Tracker booklet' we here have already produced. ......... http://www.echorenovate.com/new-book---make-a-solar-tracker.php And add a link for the PCB's. The Book Index....

Everything is possible, just give me time. 3 HughP's 3.7m Wind T's (14 years). 5kW PV on 3 Trackers, (10 yrs). 21kW PV AC coupled SH GTI's. OzInverter created Grid. 1300ah 48v. |

||||

| Clockmanfr Guru Joined: 23/10/2015 Location: FrancePosts: 429 |

Grogster, I have talked to the 3 most important World wide Forums Moderators and they understand where I am coming from and that this OzInverter should be published and OUT there. But I am not keen on downloading PDF as its easily hacked and sold on by the unscrupulous, and I do not have the necessary Police-ing facilities.

Everything is possible, just give me time. 3 HughP's 3.7m Wind T's (14 years). 5kW PV on 3 Trackers, (10 yrs). 21kW PV AC coupled SH GTI's. OzInverter created Grid. 1300ah 48v. |

||||

Grogster Admin Group Joined: 31/12/2012 Location: New ZealandPosts: 9308 |

Hi there.

Book loooks FANTASTIC!

Well done, you.

I know where you are coming from on the PDF, and I also think you should NOT offer that at this stage. To paraphrase you for a moment, it is really easy for anyone with a flatbed scanner to scan a printed copy and start selling off electronic copies of something they did not even write. Ill-gotten gain is what it is all about to some - it sucks, and I totally understand your reasons. I would like to purchase a copy of the book though, when you are ready to sell. As to the PCB supply, yes, I would be happy to get the boards made and supply them via my website. I can offer just the blank PCB, or a kit of parts with the PCB. It would be easier for us to communicate about that in emails, so I will PM you about this. Smoke makes things work. When the smoke gets out, it stops! |

||||

sparksandsmoke Newbie Joined: 14/05/2015 Location: IrelandPosts: 12 |

I follow this thread about inverters (and similar threads) with great interest, although I have little to contribute. Clockmanfr, I applaud you for your publishing efforts. I would like to buy a copy of your book when it's available. Your caution re the PDF route is well founded, I agree. As a long-time fan and supporter of Hugh Piggott's wind turbine work, I've seen his intellectual property ripped off and copied by unscrupulous individuals on many occasions over the years. *back to lurk mode* |

||||