|

|

Forum Index : Electronics : Time for a new Warpinverter build - #2

| Author | Message | ||||

| Murphy's friend Guru Joined: 04/10/2019 Location: AustraliaPosts: 648 |

OK Roger, this thread has gone a bit off the mark now but I'm still curious: Have you got that warpverter working yet?  |

||||

| solarsim Newbie Joined: 10/01/2021 Location: AustraliaPosts: 10 |

Had a small gremlin in the spreadsheet. Sorry for quick update, but i couldn't let a small error stay there. (I wouldnt want a bad eeprom file being used and causing a problem.) batch32_wholewave_mk3.ods.zip and here is the spice sim for the dc dc isolated converter. bose-mk2-ver1.asc.zip |

||||

| rogerdw Guru Joined: 22/10/2019 Location: AustraliaPosts: 852 |

Hi Klaus, I'm still muddling along sporadically. Finished off another transformer on the weekend. There's always something to drag me away!!!  Cheers, Roger |

||||

| Godoh Guru Joined: 26/09/2020 Location: AustraliaPosts: 458 |

Hi Roger, I am curious about what technique you are using to wind your transformers. I have seen plenty of them wound using a shuttle, but also somewhere seen people using a hoop of sorts. Just wondering what is easier, I have two cores that I want to wind soon. Cheers Pete |

||||

| rogerdw Guru Joined: 22/10/2019 Location: AustraliaPosts: 852 |

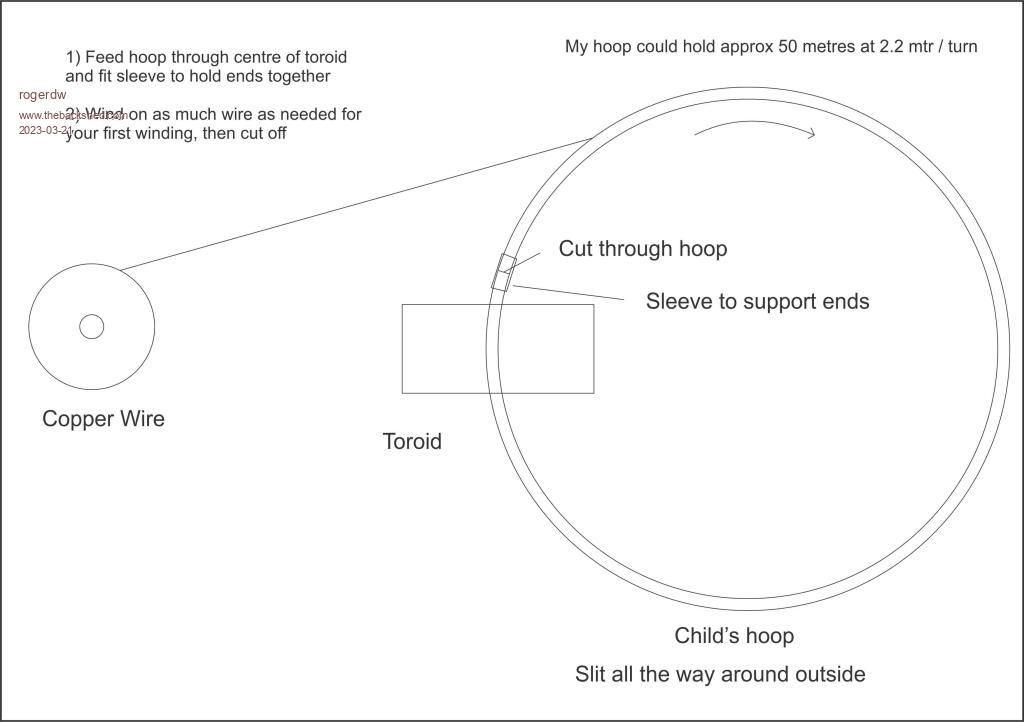

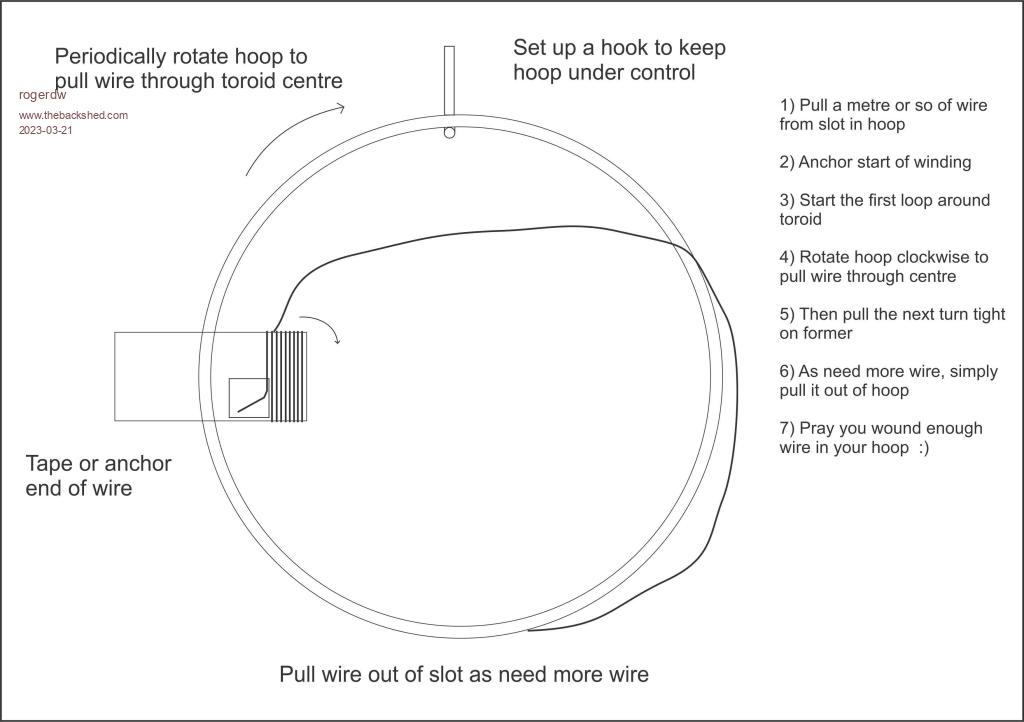

Hi Pete, I used the hoop method to wind the toroids. I found a child's hoop and cut a slot in the outer circumference using a Dremel, though a hacksaw would possibly have worked better. I then cut through the hoop so it can be fed through the hole in the toroid ... and made a sleeve to hold the ends together again, so it didn't flop around. Once the hoop was through the toroid centre, I wound the required length of wire onto the hoop. Then cut it off. Next step was to anchor the wire end to the toroid and start winding. It sounds complicated perhaps, but once you start it becomes a piece of cake. I created a hook to support the hoop so it didn't become difficult to handle. The hoop was quite stiff even with the slot in it ... so contained the wire well ... and it was easy to hold the wire in my left hand so it didn't come loose on the toroid ... and use my right hand to slide under the wire and round the hoop to pull a bit more out. When I needed a break, I would clamp the wire against the toroid with a large plastic spring clamp like an oversized clothes peg and it would remain nice and tight. Anyway, check out the diagram and pictures and if you have any more questions, yell out.    Cheers, Roger |

||||

| tinyt Guru Joined: 12/11/2017 Location: United StatesPosts: 438 |

Same concept as Roger's, but I used bicycle rim so I don't have to do the slitting. But sometimes the wire becomes loose on the rim and I have to put temporary masking tape so that it does not jump out of the rim. Edited 2023-03-21 23:06 by tinyt |

||||

| rogerdw Guru Joined: 22/10/2019 Location: AustraliaPosts: 852 |

I did try a bicycle rim first too tinyt but had the same problem with it coming all loose. In fact you can see it in the background of my photo above. I got my idea from Klaus (Murphy's friend) after he used some poly pipe I think it was ... and I kept thinking about the same concept ... but with stiffer plastic. Then I came across an old hoop upstairs in the shed and grabbed it.  Cheers, Roger |

||||

| Murphy's friend Guru Joined: 04/10/2019 Location: AustraliaPosts: 648 |

Excellent description and drawings there Roger. That should be clear enough for a first time toroid winder to grasp the technique. A stiff hula hoop type ring is best to trap the wire within but a slitted poly pipe (19mm) will do if hula hoops cannot be found. This will be very floppy until a few turns of wire are on it. With bicycle rims, being usually metal, there is the danger of the spoke holes scraping the wire already wound on the toroid, beside the open rim not trapping the wire on it securely. The main reason I chose this method over the spool or shuttle type is that it keeps your carefully straightened recycled wire straight. The more one straightens and then bends copper wire the stiffer it gets, the sharp turns of wire on a shuttle or (fit through toroid hole) spool negate any previous wire straightening and the result can be quite amateurish looking. |

||||

| Godoh Guru Joined: 26/09/2020 Location: AustraliaPosts: 458 |

Thankyou for the explanations, I like the look of what you did. Both methods look good, I will try the plastic hoop first. Thankyou for the photos and drawings, they will help a lot. As I said I have only seen shuttles used before, they looked pretty cumbersome. Cheers Pete |

||||