|

|

Forum Index : Electronics : Switching DC with AC rated contactors?

| Author | Message | ||||

| Haxby Guru Joined: 07/07/2008 Location: AustraliaPosts: 423 |

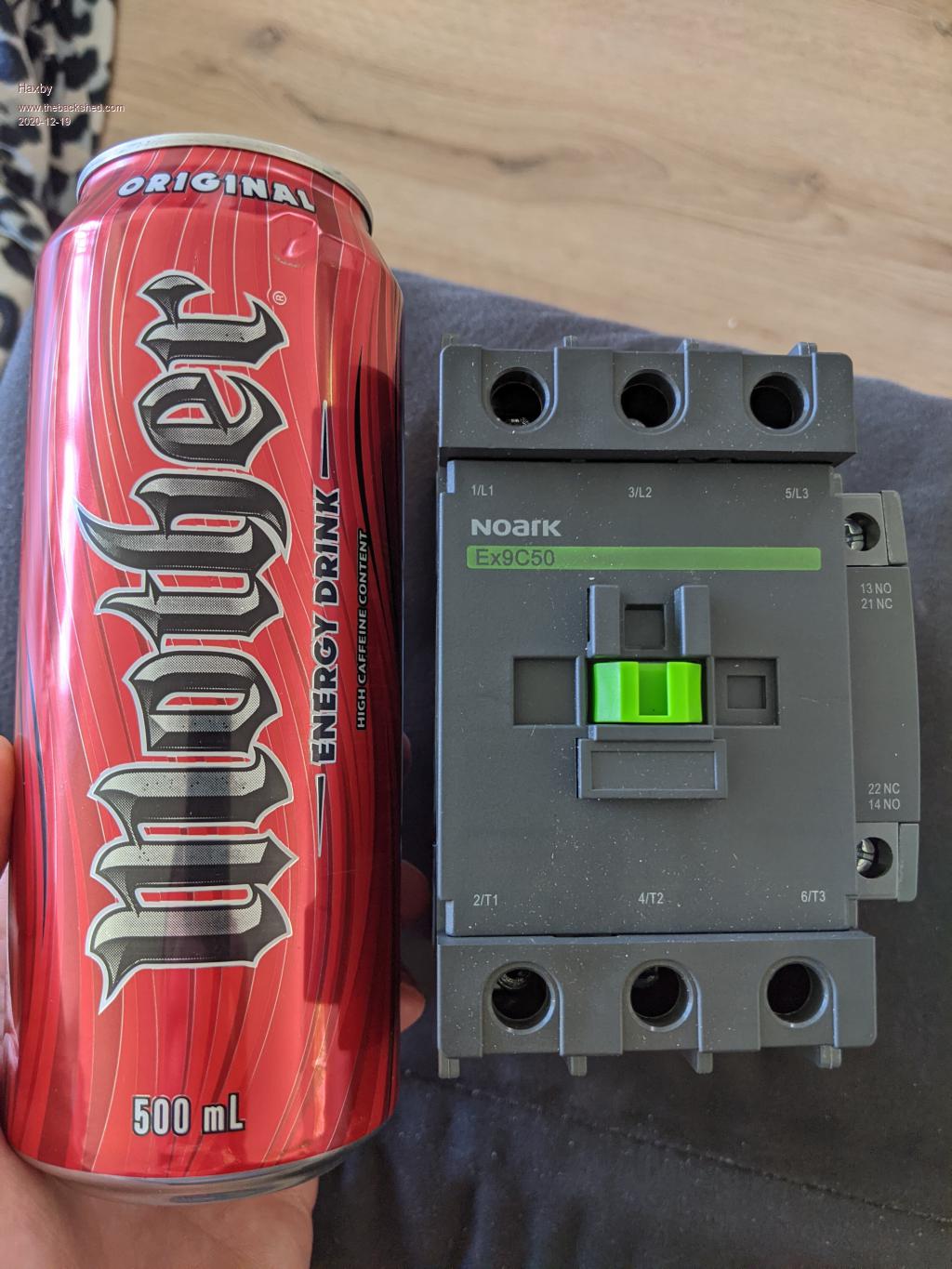

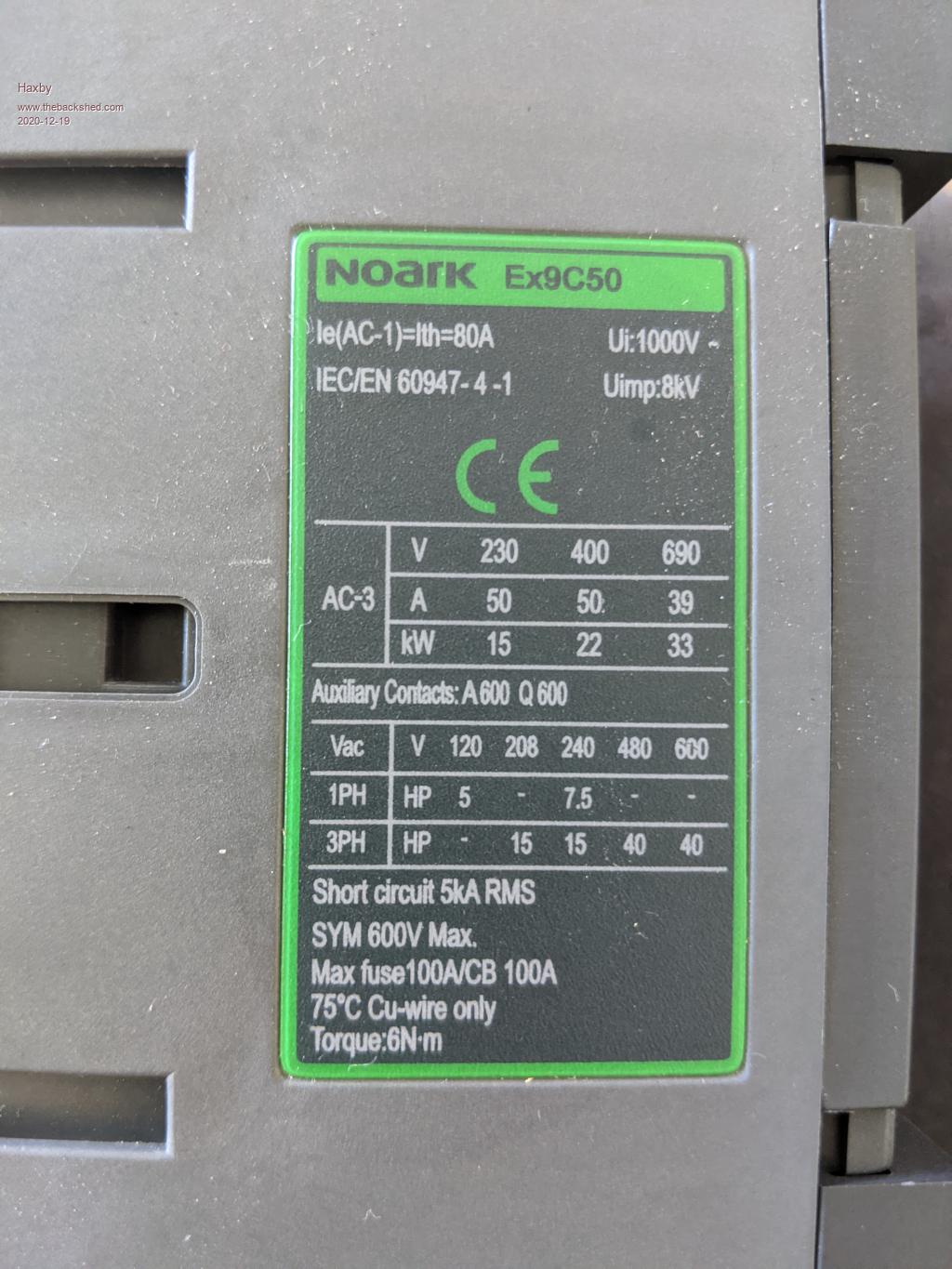

Hi all, I bought a few of these beefy 3 phase contactors for peanuts when rockby electronics were liquidating them. I don't have a specific purpose for them yet but was wondering if they would be ok to switch DC despite not being rated for DC. I'd imagine the distance between the open contacts would be the deciding factor to work out a derated DC voltage rating. Any other thoughts?   |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

I was taught the rule was a 240vac contactor was ok for 50vdc. It depends on the source and load. I've had 240vac rated relays vaporize the contacts when used on a 50v solar panel and a 50v water heater element. Closing the contacts isn't the problem, its opening them. It depends on the voltage across the contacts when opened. If its a solar panel charging a 50v battery bank, the open circuit voltage of the panel may be 70 volts, so you only have 20v across the contacts, which would be fine. But the same panel on a water heater element will see 70v across the opened contacts, enough to establish a arc. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| wiseguy Guru Joined: 21/06/2018 Location: AustraliaPosts: 1156 |

You could wire each of the 3 breaker lines in series and give it a whirl, then you have 3 times the gap and less likely for 3 arcs to start? I have seen a 30A 600VAC rated switch continue to pass current when it interrupted 10A at 120VDC (it would have been glowing in the dark) once the arc starts you have a little plasma fireball & they are hard to extinguish. If at first you dont succeed, I suggest you avoid sky diving.... Cheers Mike |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

Have to agree with Glenn. 50v dc should be fine, as long as there are no big inrush currents when closing, and opening should be fine too as long as there is negligible series inductance. It starts to get hairy around 100v, even with dc rated circuit breakers. If there is a big splat charging electrolytics on closing for example, welded contacts will almost certainly result. Maybe not the very first time, but it will happen. Anything higher can be really terrifying with mechanical contacts. Just bear in mind that continuous arc welders operate in the 15v to 45v range, dc and ac. Cheers, Tony. |

||||

| Davo99 Guru Joined: 03/06/2019 Location: AustraliaPosts: 1578 |

My " trick" for switching DC through AC rated breakers is to switch both poles at once. I get no more arcing d9oing this than I would AC. I have a 3.6 Kw Inverter up the back that has the solar input going through a couple of normal AC breakers, one on the pos side, one on the neg,and I must have switched that at least 20 Times at Full Load with No problem at all and over 50 times at different lesser power levels. I would suggest as these contactors you have are 3 phase, Wiring both sides, one with a single contact and one as suggested, in series. Alternatively use one contactor per side and wire each in series. I think you'd be safe as houses then. I have also switched DC loads with DPDT relays at near their current rating using one pole for each side of the DC and that has worked well too. The other thing I played with and had success was was using DPDT relays but not switching the power on and off but rather to a dummy load. For instance, If I wanted to switch off a solar DC input I wired a dummy load on the other contacts of the relay. The interesting thing was that to stop the arc, you don't have to have a dummy load to absorb the full power. If you switch to something that is 50% draw, there is no problem with the arc at all. I found a dummy load with 30% draw of the main input was successful on most but not all occasions. 50% I couldn't fail. I tend to think of DC based on my experiments as having " inertia" . It does not want to stop so it you give it another path to follow, it will as long as the path is wide enough even if it's not as wide as the original. If DC is switched to nothing it wants to keep going and jumps the gap creating an arc. If you switch it like train points, it is happy to leave the first line and go to the new one even if the line isn't as long. This technique probably isn't practical for a lot of things but it does work very well in my tests. The switching both sides at once which probably is the same as wiring a switch in series, has worked perfectly for me in switching up to 350V @ 10A many many times without a problem. |

||||

| InPhase Senior Member Joined: 15/12/2020 Location: United StatesPosts: 178 |

A general rule of thumb that has worked well for me over the years is that an AC switch can safely interrupt the rated switch current up to around 30 VDC. Beyond 30 volts, start de-rating. At 48 volts I'd trust a contact rated at 20 amps AC to handle 12 amps or so. With a 3 pole contractor, putting the poles in series I would trust it to do the full amp rating. The arc voltage will be 1/3, which puts each arc lower than the original rule of thumb voltage of 30 VDC. External RC snubbers also help a ton. Edited 2020-12-20 02:44 by InPhase |

||||

| Clockmanfr Guru Joined: 23/10/2015 Location: FrancePosts: 429 |

Many years ago, about 12, I directly contacted HAGER MCB research and development section. And got hold of a nice product engineer and we discussed using AC breakers for DC. He replied that there MBNB range could take up to 60vDC with no issue as long as the Amperage was de-rated by about 1/8 of the AC amperage rating on the AC MCB. 'Oztules' experimented and concurred. I use 12off Hager range for my 3off 3.7m diameter wind turbines, never let me down. Above 70 volts DC i use the high voltage DC Midnite or Outback MCB's, i understand they are made by the same manufactures in the Philippines. Between my batteries and my OzInverters i use and recommend the large 250 amp 125vDC Midnite breaker. I trust this helps. Edited 2020-12-20 05:01 by Clockmanfr Everything is possible, just give me time. 3 HughP's 3.7m Wind T's (14 years). 5kW PV on 3 Trackers, (10 yrs). 21kW PV AC coupled SH GTI's. OzInverter created Grid. 1300ah 48v. |

||||

| Haxby Guru Joined: 07/07/2008 Location: AustraliaPosts: 423 |

Thanks all. Good to know that they are not limited to just AC. I think they were $5 each, so I just couldn't pass them up. For now I will use one to regulate my 3.6kw resistive storage hot water system so it turns on with sunlight, in sync with the solar power output of the GTI- to minimise my power export. Thanks again for your thoughts! |

||||

| BenandAmber Guru Joined: 16/02/2019 Location: United StatesPosts: 961 |

wow good to know info i have a few motor starting boxes with big contactors in them along with bunch of caps and nice breakers Now the question now is can you use dc to engage the c0ntactors be warned i am good parrot but Dumber than a box of rocks |

||||

| InPhase Senior Member Joined: 15/12/2020 Location: United StatesPosts: 178 |

You could rewind the coils. If they are 12 or 24 VAC coils, you could PWM a DC voltage to maintain only the necessary holding current. |

||||

| BenandAmber Guru Joined: 16/02/2019 Location: United StatesPosts: 961 |

inphase thats a good idea i am not sure what voltage they are there is no tranny in the box just bunch of caps a big contactor a thing for lightning or surges so i think it works off one of the 3 phase voltages it may stay down by its self i dont know how the 3 phase motor starting boxes work they have a button on them be warned i am good parrot but Dumber than a box of rocks |

||||