|

|

Forum Index : Electronics : Oztules, some advice please..

| Author | Message | ||||

| grolly Regular Member Joined: 19/05/2007 Location: AustraliaPosts: 62 |

Hi, my cheap Peoples Republic wind gen has had a few hic ups lately, apart from throwing ONE of the plastic blade ends off in a bit of a blow we had, and before we could get it down, it threw another, and when I finally got it down, the third one was missing. needless to say that shimming the rear bearing carrier with the side of a coffee tin was not unexpected.. Then, a couple of months later after takeing 4 mt off the tower height,(so it made it easer to get down and up with only my partner and I),I finally got it running sweet, but the abuse that it had endured while trying to get it balanced, manifested its self at 3 30 am ( in a bit of a blow ) by deciding to shed all three blades, and if you are only 15 mt from it when it happens, it is one scary sound to wake up to, one blade buried its self within 1/2 mt from the house, and the other two were picked up some 40 mt from the wind gen, in diferent directions. so after cutting the blades, redrilling them and getting it balanced again it was back up and working fine,

bit more wind speed needed to get it going, but we have plenty of that here back to its 30 volt at 6 to 10 amps, and the 24 volt battery god was happy once more. Then, (in a bit of a blow) I was not quick enough to get it pulled out of the wind, and the regulator box decided to have a BBQ on its own, I wasnt invited till the chips were well dome fuses blown and relays fried

NOW, come on Ozie wake up, sorry I have been so long winded, this is my question... 1) would the bridge rectifiers be any good to remove and use to convert the 3 phase to dc 24 volt( it is or was a 24 volt unit, 500 W wind gen)

2) I have a 60 amp solar charge controller, could I feed the output from the bridge rectifiers straight into the charge controller, or do I need some other electronic wizardry between them? thanks Grolly I have bought the farm...now I AM powering it... |

||||

| GWatPE Senior Member Joined: 01/09/2006 Location: AustraliaPosts: 2127 |

Hi grolly, the solar charge controller will most likely control by opening the connection from the solar array. This is not desirable with a windmill. Gordon. become more energy aware |

||||

oztules Guru Joined: 26/07/2007 Location: AustraliaPosts: 1686 |

Sounds like fun for all the family. Yes you can use the bridges as rectifiers or spend a few dollars on some 35A 350v bridges. They are a little more solid than the dinky ones in your current controller. Use heat sinks (modest for your requirements, but still necessary. Either way connect up as they currently are, or like this (from windstuffnow.com)

That takes care of getting it charging. Now we need a diversion controller like this oatley controller and then a dump load for it to drive ... say 8 x 50w car headlights connected in series/parallel for 24v. Now that oatley one is for 12v but can no doubt be adapted to 24v use. Here is a long discussion I had with methanolcat in Texas regarding designing dump loads for any voltages with circuits, explanations etc etc. Someone here may know of a kit supplier for local 24v ones if it is not your cup of tea to build them cold. Ghurd on otherpower has some as well. If you want to get fancy, Gizmo has one here The solar controller shuts off the solar cells when charging is complete, the windmill must have a load at all times or it will shed it's blades in a runaway scenario. Thats why the solar controller will not suffice for this purpose. We need to load the mill at all times. So yes it is simple but requires a rectifier stage,to do the charging, and a diversion controller, and a dump load to do the battery controlling part. ....or fix the chinese thing. .........oztules Village idiot...or... just another hack out of his depth |

||||

| GWatPE Senior Member Joined: 01/09/2006 Location: AustraliaPosts: 2127 |

Hi grolly, the new chinese controllers apply shorting pulses to the windings to provide voltage regulation. These are potted units. I will use one on my F&P mill during testing. Placing shortened blades back onto the mill upsets the furling geometry. You should check out the balancing and assembly tips that eco-innovation use on these machines. Gordon. become more energy aware |

||||

oztules Guru Joined: 26/07/2007 Location: AustraliaPosts: 1686 |

Gordon, This has me curious "the new chinese controllers apply shorting pulses to the windings to provide voltage regulation." I am having difficulty working out why they may try to voltage regulate a battery regulated system.... unless you mean they were boosting, and then it has merit, or they were bucking and trying to extract some more current that way. If this is the case, then depending which way they are going, Grolly may have a few more problems than first thought. If they are Bucking, then his impedance will be too high...(may cause burn out or stall) but by how much?, or if they are boosting, then his impedance will be too low (late cutin or overspeed)... by how much. Grolly, if what Gordon is alluding to is true for your model, then a rewind or fixing the controller may be better ways to proceed. The fix I described in the above post, was for a "normally wound" turbine (which is what I think you think you have). If this one is significantly reliant on a continuous buck or boost mode, then the whole thing will be unbalanced by straight rectification. Gordon also mentioned that your shorter blades would upset your furl point, and he is correct, it also may be why it cooked the controller. It may have overpowered it in high winds.... which makes me feel that a buck circuit was used. Your photo's of the innards were blurry, but you seemed to have shown a cooked resistor (probably the load sense resistor) and some blurry diodes, and a cooked relay. Could you get a pic of the whole board and innards, maybe Gordon will recognise the topology and we can move forward from there. .........oztules Village idiot...or... just another hack out of his depth |

||||

| GWatPE Senior Member Joined: 01/09/2006 Location: AustraliaPosts: 2127 |

Hi oztules, the new design chinese regs are potted, so little can be seen from the outside. I do intend to check the conrtol mechanism with a CRO. My initial testing on a power supply confirmed the input shorting principle, prior to the rectifier. This is one of the methods I use on my mill. I do not actually regulate the input, but turn off the mill for a set time. This is the first stage unloaded protection method I use. The chinese reg attempts to limit the mill voltage by controlling rpm once the load voltage setting is reached. This system dissipates the power in the mill, and apparently saves on external dump resistors. These units are not expensive, so repairing may not be economically justified. We are in a throw away society. The new units cannot be repaired successfully either. The regs are not smart, with buck or boost ccts. Gordon. become more energy aware |

||||

oztules Guru Joined: 26/07/2007 Location: AustraliaPosts: 1686 |

Thanks for that Gordon. Good to see you are back on board. I will assume you had a good holiday.

Well if it is as you describe, then the simple rectifier and dump conversion load and diverter will work out well. Or he could go and get another chinese controller... which with his shorter blades will probably burn up again, and perhaps unfairly heat the stator up for no good purpose. I am guessing the relay was for braking purposes for when pulsing was not enough to control it. That only leaves the tuning of the furl point to overcome, which may or may not be critical... I don't know how much overhead these chinese things have. If he replaces the controller with another, this will certainly have to be addressed, as higher rpm before furl will probably overcome the "dump to stator" method they were using. .........oztules Village idiot...or... just another hack out of his depth |

||||

| GWatPE Senior Member Joined: 01/09/2006 Location: AustraliaPosts: 2127 |

Hi oztules, The newer controller would be less affected by shorter blades as there would be less torque to overcome by the stator shorting method. The new controller seems to be the chinese answer to restricting the power output to a maximum 200W for a 24V system. I think there is a problem with the furling mechanism as I have known a 24V chinese mill without controller that produced over 700W. Clearly the furling was inadequate. Gordon. become more energy aware |

||||

oztules Guru Joined: 26/07/2007 Location: AustraliaPosts: 1686 |

Gordon, That was my first thought too, but in stronger winds, the pushing force on the blade set will be a bit less for more rpm before enough torque is exerted on the furling to work.. that why I concluded we would actually get a higher emf in this situation... of course I may have muddled this up a bit, but that's what I think would happen in this instance. The efficiencies will change as we generate with a smaller faster blade set with an excess of wind. The other part of me says power is power and should exert the same forces regardless of diameter, but... seeking force (which I don't pretend to understand) can cause this to not be the case all the time. So I think of it as too much weight on the tail on a small machine... and with enough blade to runaway in high winds as he described. I'm fully prepared to be re-educated on this point though If it is an iron cored alt, then there is even more chance that inductive limiting will help the runaway (Would this help decrease the required torque on the blades for increased rpm?) The AWP here seems to top out at 1.5kw, and after that spins faster, but the output does not climb with it at the same rate as before. When we overdid the tail weight, this is what appeared to happen. The fact that he loses blades makes me think this may hold some water. This was supposed to make some sort of sense.... ......oztules Village idiot...or... just another hack out of his depth |

||||

| GWatPE Senior Member Joined: 01/09/2006 Location: AustraliaPosts: 2127 |

Hi oztules, I think your description confirms things. My comment above relates to the newer type controller. The mill with smaller blades will have less chance of furling and hence the smaller blades could spin even faster. I think the main problem will still be problems with furling and the mill accepting too much power from the wind. The chinese design does not address the overpowering that can happen in strong winds. There are many related parameters in windmill design. The chinese design has pretty well fixed furling pivot points. A simple part fix could be to replace the heavy sheet metal fin with plywood. I see most problems stem from a greed for big power output numbers. I have found that it is better to be more conservative at the top end power levels. Better to have a machine furl than continually replacing things that break. It is better to limit to what happens 80% of the time, than hope things still hold together in a storm. I started out with a heavily conservative system and gradually increased output. Reliability is a high priority for a mill in a suburban residential location. The chinese windmills are probably OK in a paddock 100m away from any buildings. I have seem many broken. Usually following a storm. Gordon. become more energy aware |

||||

| grolly Regular Member Joined: 19/05/2007 Location: AustraliaPosts: 62 |

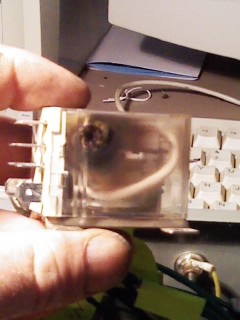

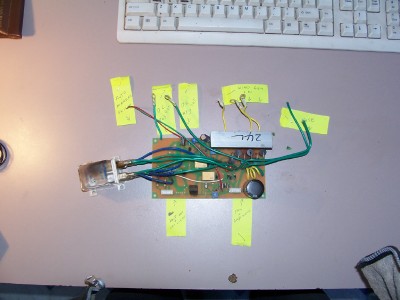

Hi Oztules and Gordon, here is a few clearer (I hope ) photos. I had a look at the Oatley ones and I think I could put one of them together... at a pinch.. the mill had " FD500" on the side of it

the square yellow things are "hrs1h-s-dc24v 1a 120vac 1a 24vdc" the big cap is "100v 2200uf(m)" the six round things are"6A10 hch" the small blue cap at the back is"35v 220 uf" the three rectifirers are"kbu808" the three transistors are" 2n 5551 b998" the front one has had it's face blown off the orange resistor is" 1uf j 63mkt" the front 3 leled thing is " .013 AN7824" the other 3 leged thing at the rear left is" nec 2p4m p92" I can't read anything on the large green resistor the relay is " asiaon jqx-12f 30A-AC power relay" and has dc24v on the coil inside if you need to know colors of resistors etc let me know. What is the concensus? can I run the oakley charge controller/dump on my mill,useing the Oatley rectifirer, if I address the furling weight,or would it be better to order a new set of blades for it and try and repair this BBQed one ? what do you think of the Air x 48 volt unit? Geoff I have bought the farm...now I AM powering it... |

||||

oztules Guru Joined: 26/07/2007 Location: AustraliaPosts: 1686 |

The board if fixable. So far it looks to be a voltage regulator, perhaps some diodes (6a10's have been hot) a 160v npn tranny and damaged/dead load resistor that provides the power to the voltage regulator. There are no exotic parts on this thing. I would have a better idea how it worked if I could read those carefully done tags that show where the wires come and go to, but never mind. I would probably go for 2 or 3 of the big 35A rectifiers rather than the oatley 3 ph rectifier. Bit expensive for my taste. Like I say, you are only rectifying small currents (comparatively). If the bridges in the unit are ok, you can use them as is. Just get rid of the 6A10's, and you can hook up to the dc there to the batteries. (perhaps cut the track to the yellow 24v relay to isolate the whole lot... but new 35A 350-400v ones would still be better. For the dump converter, read this and see if you can do it. Ghurd sells them assembled I think, there may be others over here, The oatley one seems a little expensive and incorporates a backemf controller similar to the chinese one.... which got us into this mess in the first place. If you have a third party dump load car lights etc) it is very difficult to come undone. It means the fet (from the diverter) will be switching resistance only, which beats the hell out of trying to handle high inductive loads of an overworked windmill..... which I assume didn't help that relay any. (If I could read your tags, I would know what this relay actually did.. is it kill function, or part of the backemf dump system..). I wouldn't get another chinese one, as from what I can read on the net so far, failure is the norm rather than the abnormal.... but the mills seem ok (maybe iffy bearings) although you only hear about the ones that fail I guess. As for the blades, if they are sound, and you fiddle with the furling to bring it on a little sooner, it won't hurt, and with a seperate dump load, it should be fairly robust with less things to go wrong, and all of them you can fix easily. Decreasing the tail weight seems to be the simplest way to initiate earlier furling. As Gordon pointed out, we want to be working all the time with most of the wind, rather than some of the time with all of the wind. The airx seems to have it's own problems, and less easily overcome. .......oztules Village idiot...or... just another hack out of his depth |

||||

| grolly Regular Member Joined: 19/05/2007 Location: AustraliaPosts: 62 |

Thanks Oztules, Just for intrest sake, from the top left going clockwise the tags read...Auto/manual switch...dc out pos...dc out neg...wind gen in...fuse...fan and Amp meter...red and green leds and volt meter... The controller that Ghurd has seems within my capabilities to assemble...I think...and at that price I will get two just incase I stuff up one. Are the 35 A 350 V bridge rectifiers that are advertised on eBay suitable? (my nearest smithy dicks /randy /rat shack are 1 and 1/2 hours away, so to pop down to the shop for some bits kills half a day and about $40 of diesel)so anything I can get posted to me is a big saveing. Question.. am I right that Ghurd's unit regulates the chargeing of the batteries by putting a load on them( spotlights) when they reach float(27.4V)and the lights stay on till the bank reaches low point(24.6v), or the mill stops? The battery bank is 12 x 500w 2v sealed agm, load is 1 x 24v pressure pump. (when I can get the 24v 3000w inverter fixed,(ceased to function with a 1200w soldering iron plugged in to it) that will be on this bank too) The bearings in the mill are still in perfect order, it hammered out the bearing carrier, aluminium alloy, both front and back, the front one took the shimming well, but the back one was somewhat ovoid, 4 goes at getting it to run true. "The airx seems to have it's own problems, and less easily overcome." What are the problems with the Air-x? Thanks for all your help Geoff I have bought the farm...now I AM powering it... |

||||

oztules Guru Joined: 26/07/2007 Location: AustraliaPosts: 1686 |

The Air-x:.... Here is an owners report on the Air-x a bloke called Jerry from USA.... I own a SW-403. Let me be as gentle as I can. In terms of power output and startup IT SUCKs. In terms of noise IT SUCKs. In my road/truck wind test the most I could get was 325 watts from the 403 at 30 mph. It doesn't start charging till about 13 mph. At about 25 mph the noise is like a small jet. My neighbors 400 ft away didn't like it. You can build a far supperior machine and for less money. or a quote from Ed from Windstuffnow : "I'm with Jerry on the Air 403... you would get much more satisfaction donating the money to a charitable cause.." and of course from RonB (wdyasq) we have the following words of wisdom: "Before investing money in a wind device one needs to determine if the resource is there to run it. According to their information sheet and reports it takes a small hurricane to get any power out of many of small commercial turbines - Air-X included. In very light winds no turbine will produce usable power. Comparing 'homebuilt'-DanB/Otherpower style with 'Air-X', there is not much of a contest. For electrical production the 'DanB' type wins. For noise, I'll put money on the Air-X." However, if you live in a wind corridor, and are deaf, it is a survivable machine. Ghurds controller holds it at float voltage. Whilst ever it tries to go past the float, it turns on, as it comes under that float it turns off. This means it can pulse slowly if there is plenty of power coming in above float (more on than off), fully on if overload of power is coming in above float, or more off than on if little power is coming in above float. It should not discharge anything under float. Whenever the battery is below (I assume 27-28v) float, the dump is off. It is realy just a clipper, it clips off any voltage above float. It does not pretend to be a battery management system (equalising is your job from time to time), just a battery saving system to stop over charge... nothing more , nothing less, The bridges on ebay are fine. Even the 8A flat ones in your box will do if they are still ok. I would tell you to send the chinese thing here to fix (for nothing), but I see no point in fixing a bad idea. Anything similar to Gills pic will do. Have fun ........oztules Village idiot...or... just another hack out of his depth |

||||

| grolly Regular Member Joined: 19/05/2007 Location: AustraliaPosts: 62 |

Hi Oztules I did what you said, and took out the yellow relay, and while the iron was hot, took the rest of the stuff off too,What should I have left in?

As is, it put out 30v and with a little more wind, went to 53v, no load. I will do some more testing tomorrow, ""Murphy's law No 231543, when you want to test a wind gen the wind will drop to nothing after the first test, just so you know it is working, but do not how good or bad the output is "" Grolly I have bought the farm...now I AM powering it... |

||||

oztules Guru Joined: 26/07/2007 Location: AustraliaPosts: 1686 |

Looks like you have a functioning bridge to drive the batteries. The batteries will pull it's voltage down to 24-30v depending on the state of charge. It will operate no differently than before until it gets up to a certain power level, before it probably tried to limit it, now it will go toward charging the batts and later to be dumped in your soon to be built dump load if over 29? volts... depends on your operating parameters you set on the Ghurd controller. At least you can put some amps into the batteries (if you manually look after them.) When charged up, short the mill in a lull in the breeze to kill it...until you decide to fire it up again... h Hopefully the Ghurds controller will turn up quickly. It will give you time to fashion a dump load anyway. The second Ghurd controller could probably be fashioned to make the generator start up at some per-determined voltage. and the dump load could turn it off. Possibly the intervening time could be used to get the furling to work properly and early enough to make this a reliable system. ........oztules Village idiot...or... just another hack out of his depth |

||||

| grolly Regular Member Joined: 19/05/2007 Location: AustraliaPosts: 62 |

Thanks for all the help oztules, where would I solder the dinkey little amp and volt meters onto the board so I can get some idea what is going on? Grolly I have bought the farm...now I AM powering it... |

||||

oztules Guru Joined: 26/07/2007 Location: AustraliaPosts: 1686 |

Grolly, Trying to look at your board, I have a suspicion that the amp meter has a shunt across it in the form of that yellow loop of wire. So, the dc pos going to the battery needs to be cut, and the meter put in series with this line with the yellow shunt directly "shorting" across the meter. The meter will read the tiny voltage drop across the yellow shunt (coil). At least that is how it appears. The volt meter just goes in parallel with the battery lines ie across the b+ b- . Will draw a diagram if this is not clear. An off the shelf amp meter would likely not need the shunt. Do not put your amp meter in series without the shunt as it will cook it in seconds... if it works as I suspect. Looking at the pics again, the skinny wires support this theory. ...........oztules Village idiot...or... just another hack out of his depth |

||||

| grolly Regular Member Joined: 19/05/2007 Location: AustraliaPosts: 62 |

Thankyou Oztules, the battery god has been appeased, the mill was going all day today, only slowly, not much wind, but did notice 30V and 4A on the meters, must have done it right. thanks again for putting up with the electronically challenged old fart. Will keep you informed as soon as I receive the controllers. I spent the day cementing the base pole for my next wind gen,( and 11x 6 ft permapine posts for the back fence) and tomorrow I will see if I can complete the VWT that I started a few months ago, been to busy lately to do much on it. Grolly I have bought the farm...now I AM powering it... |

||||

oztules Guru Joined: 26/07/2007 Location: AustraliaPosts: 1686 |

At least you will know whats in the box now. my pleasure .........oztules Village idiot...or... just another hack out of his depth |

||||