|

|

Forum Index : Windmills : Wind Grid tie inverter 30-540VDC input

| Author | Message | ||||

| DaveP68 Senior Member Joined: 25/11/2014 Location: New ZealandPosts: 292 |

Came across this Wind Grid Tie Inverter with a 30-540 VDC input range which is designed for Wind Turbines. Their are 2 kW and 3 kW versions. Wind Power Grid Tie Inverter With new sophisticated, programmable control and fast responding (MPPT) algorithms, the wind turbine versions out perform any other non dedicated inverters. This makes them suited for most types of PMA's and in my opinion perfect match for F&P stators which also won't require any difficult rewiring. Quick and easy to install, in according with AS4777 standards. There are realities if you do not accept, will lead to frustration because you will be spending time on wrong assumptions and the results cannot follow! The Dunning Kruger Effect :) |

||||

| brucedownunder2 Guru Joined: 14/09/2005 Location: AustraliaPosts: 1548 |

Very interesting ,Dave. I wonder if our electrically smart members will be able to delve inside and one day convert the many junked inverters that appear in our metal scrap yards these days ? I have 3 working inverters(PV) that are just waiting for conversion ,,or pv use ,,whatever comes first.. Thanks Dave Bushboy |

||||

| DaveP68 Senior Member Joined: 25/11/2014 Location: New ZealandPosts: 292 |

Hi Bruce I'm sure 1 or more of our electrically smart members may crack how these types of inverters really work inside. I know Warpspeed has an understanding of the what not to do and a few ideas on a possible working system. I do have an electrical/electronics back ground but most of the time has been spent if the Radio Frequency field. Have no experience on inverters but now plan to gain more understanding of them through what I've learnt so far. Cheers David There are realities if you do not accept, will lead to frustration because you will be spending time on wrong assumptions and the results cannot follow! The Dunning Kruger Effect :) |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

Its not particularly difficult to do, it just requires someone that has the need and the cash and the motivation to do it. There would be two parts to this. The first would be a boost converter to step up whatever incoming dc voltage is available to a fixed (and quite high) output dc voltage. Then followed either a standard "normal" free running inverter, or a grid tie inverter. The clever part would be drawing just enough power from the wind turbine to stay just below blade stall, under wide and constantly varying wind conditions. I don't think any type of feedback system would respond rapidly enough to be useful in gusty conditions, although it might work to very slowly self adjust for a constant steady on shore breeze. Most of us live well away from the ocean, and have to deal with local turbulence caused by trees, buildings and local topography. And it would be very difficult for a feedback system to track without the machine constantly going into blade stall and then having to slowly recover. Much better would be a feed forward system (instead of feedback). What that would do is use an independent anemometer to measure instant real time wind speed, and very rapidly adjust the electrical loading on the wind turbine to suit. For that you need to have a lookup table or some means of programming so that the system knows EXACTLY how much to electrically load the machine for every wind speed from zero to safe maximum. In its simplest form it could be a row of potentiometers you get to tune manually. Or it could be a lookup table in PROM that needs to be set up initially. Or even some kind of very gradual self learning algorithm. Think of it like the engine management system in your car. That has no feedback, but it "knows" exactly how much fuel and how much ignition timing to give under widely varying engine speed, load, and temperature. You can race up through the gears with operating conditions changing incredibly quickly, and there is no delay or possibility for instability, because every possible combination of inputs (rpm, throttle opening, airflow, water temperature, air temperature) has been very carefully pre mapped to give the correct outputs for fuel and ignition. With our wind turbine we are lucky, we have ONLY ONE input variable, wind speed. And one output variable, machine power loading. All we need to do is provide "something" so that our electrical loading tracks the wind speed with the correct and exact relationship. It will be very fast acting and have total stability without any possibility of surging or going into blade stall. A PWM boost converter could then step up the available voltage to something usable and fairly constant so it can contribute power to an existing power source. That existing power source could be the grid, a battery, or another alternative energy source such as solar or hydro. Or a mixed combination. Cheers, Tony. |

||||

| brucedownunder2 Guru Joined: 14/09/2005 Location: AustraliaPosts: 1548 |

So, Tony(Warpspeed and others) ,,, that really is what we have now --`A Battery' 48 volts in my case. I just had a quick look at my couple of windyboy inverters --they accept dc voltage from around 150 -400 volts , I think .. so what would be within the dc input window would have to be just that ,,,so ,this is where the battery comes in ,maybe, ? it's a constant source of "Bank" that the inverter would operate to ? But, how do we get an inverter ,like we are talking about , to work at 48 volts or very close to it ? thats the problem. heaps of backup in the "Bank" just getting the inverter to be happy to work at around that "bank" voltage of 48 v. clear as mud,Eh? Bruce Bushboy |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

The thing is you need a PWM dc to dc converter that can change the loading on the wind turbine and convert the wind machine output to the battery voltage. Now a buck converter is not going to work, because it can only reduce the voltage. And a boost converter is better, but it can only increase the voltage. Once the wind machine output increases up to the battery voltage, you are screwed with a boost converter, because it can only increase voltage and not reduce it, so you lose control. So a boost converter is the simplest to implement, but the battery voltage needs to be made higher than the highest voltage the wind machine can ever reach, which is not always convenient. There are other topologies that can both boost and reduce voltage, but those usually invert the output. In other words if the wind turbine generates a +ve voltage, your battery needs to be -ve with respect to ground. Or you can use a conventional +ve battery voltage with respect to ground, and convert your wind turbine for -ve output. Many ways to go about all this, but I suppose it depends on what you already have. Cheers, Tony. |

||||

| DaveP68 Senior Member Joined: 25/11/2014 Location: New ZealandPosts: 292 |

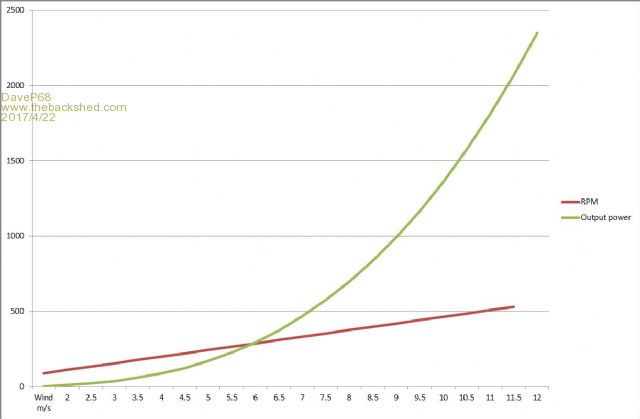

Hi Tony I have an idea along the lines of, what ever PMA is used they have very predictable electrical characteristics (When load matched). I other words if you let say an F&P stator operates as a constant current output device, then the voltage & RPM values will remain proportional as they go up & down. This is a big clue as to how these "Wind Power Grid Tie Inverters" are able remain in control over wide input voltage range (30 to 540 VDC in this case). The only variable left is the power curve of the wind turbine blades over their operating RPM range (cut in to peak RPM). Refer to the graph below of a projected power curve from 3 m diameter blades in 2 -12 m/s wind speed. The corresponding RPM range is 80 - 530 which will be proportional to the PMA output voltage.  This fits perfectly with an F&P stator(s) operating with an output voltage range of 80 to 530 VDC. Believe me I know the exact configuration that will match this voltage range very closely using 3 stators on 1 shaft to get up to 2.4 kW peak. The "Wind Power Grid Tie Inverters" have 40 point programmable, linearly extrapolated power curve, via inverter display, to match the output of a specific wind turbine. So you are correct in that a buck converter is not the device to use. David There are realities if you do not accept, will lead to frustration because you will be spending time on wrong assumptions and the results cannot follow! The Dunning Kruger Effect :) |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

David, You are quite right, the great unknown is the actual turbine (diameter, pitch, number of blades). That, and the characteristics of the PM alternator produce something with very fixed and repeatable curve, but an initially unknown curve, especially for a completely home brew combination. A "magic box" might be able to optimize loading similar to a solar perturb and observe algorithm. But if the wind is gusting, it really has no hope of following the action, and may go into a speed surging instability. That is the problem with any feedback system. It says oh sh*t !!! and then applies too much correction, then has to recover. Then repeats. A feed forward system says o/k we are seeing 4.35 m/sec at this instant and we will pull XX.X watts out of the machine at that exact wind speed, because that is what my lookup table says it can do. That may be slightly less than is possible, or the blades may slightly stall. But its going to be a stable condition. A small anemometer can accelerate and decelerate very quickly, much faster than the rpm of the main rotor. So the power output can be very rapidly modulated to follow fast gusts and lulls, without the main rotor rpm having to change. So you generate a table of numbers to match your green curve exactly. Wind speed versus output watts. And it can be made absolutely any shape, with as many correction points as you wish to have. Cheers, Tony. |

||||

| Clockmanfr Guru Joined: 23/10/2015 Location: FrancePosts: 429 |

Have a look at 'Hugh Piggott's' site, and 'Kitestrings' posts on Fieldines. Both have tamed the Midnite MPPT, and the Tristar MPPT, controllers for their particular Wind Turbines, and have given their MPPT points settings to us all for duplication. There settings are interesting and could be used on a self made arrangement, but boy it would need to be bullet proof.! Personally, after 9 years of flying 3 off Hugh Piggotts design of 3.7m diameter, and watching them do there stuff, yes, even in Hurricane winds, I am sticking to clamping them to a big battery bank, and diversion controller excess to 8kW of heater loads. Everything is possible, just give me time. 3 HughP's 3.7m Wind T's (14 years). 5kW PV on 3 Trackers, (10 yrs). 21kW PV AC coupled SH GTI's. OzInverter created Grid. 1300ah 48v. |

||||

| DaveP68 Senior Member Joined: 25/11/2014 Location: New ZealandPosts: 292 |

Hi Clockmanfr Thanks for your contribution. As for making these MPPT inverts bullet proof they still require a dynamic brake control that would cut in with very high winds when volts exceeds say 540 input level. A dynamic brake is easy to build and I currently have one that operates between 400 & 500 volts but current limited to 4 Amps. They clamp the voltage so any excess power is dissipated as heat via resistor bank, but the inverter remains connected producing power if say a Grid Tie version. Can you provide a link to Hugh Piggott's' site, and 'Kitestrings' posts on Fieldines? Did a search, but it brought up lots of results. There are realities if you do not accept, will lead to frustration because you will be spending time on wrong assumptions and the results cannot follow! The Dunning Kruger Effect :) |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

As these are specifically designed for wind turbines by having a very low cut in voltage of only 30v, I would be very surprised if there was not already provision for a high voltage dump load on the input side. Its also likely that the MPPT software is quite a bit different to a solar MPPT algorithm. All speculation on my part, but if building a grid tie specifically for a wind turbine application, all the rather different requirements have probably already been understood and met. Sounds like a very nice inverter. Cheers, Tony. |

||||

| DaveP68 Senior Member Joined: 25/11/2014 Location: New ZealandPosts: 292 |

Hi Tony I think you are correct that a form of dump load is probably on the input side. Just can't see any mention of it in the specifications. The MPPT algorithm will probably do a good job of keeping the turbine under control in high wind conditions without the need a dump load kicking in. There does still need to be some form of dump load action in the event of power failure with no grid connection available. Yes they do still look like a nice inverter. Cheers David There are realities if you do not accept, will lead to frustration because you will be spending time on wrong assumptions and the results cannot follow! The Dunning Kruger Effect :) |

||||

| Clockmanfr Guru Joined: 23/10/2015 Location: FrancePosts: 429 |

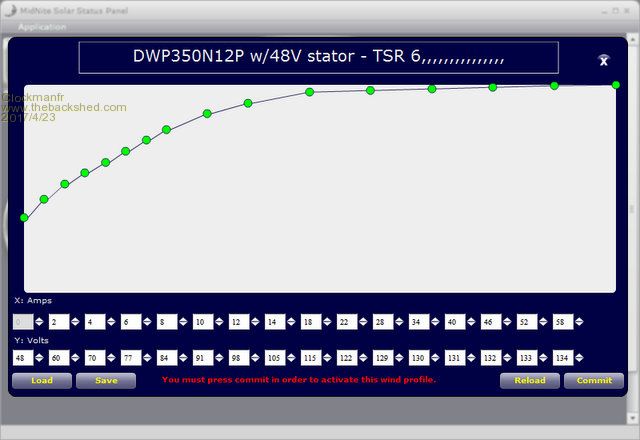

Hi DaveP68, Darnned if I can find Hugh Piggott's MPPT settings. I know it was on his last website, as Morningstar sent him a MPPT controller to test, and I feel sure Hugh published his settings for his big Wind Turbines, but where? Searching quickly on 'Fieldlines' on what I can recall.... Stuff from... 'Flux', 'Chris Olson' and 'Kitestrings'. http://www.fieldlines.com/index.php/topic,148468.msg1031191.html#msg1031191 http://www.fieldlines.com/index.php/topic,148063.msg1026343.html#msg1026343 http://www.fieldlines.com/index.php/topic,145104.msg984085.html#msg984085 The below is Chris Olsen post on the Midnite Classic settings. http://www.fieldlines.com/index.php/topic,147278.msg1016449.html#msg1016449  Sadly 'Flux' died last November, so his original MPPT stuff is perhaps lost. I did ask 'Chris Olson' to document some of his work, but was rebuffed. Forum members die its going to happen..... I just wish more folk would document stuff. Forums are great resources, but a reorganization, search engines getting rubish, etc ..... And yes 'Warpspeed' I have read all your inputs, and 'poida's' work with great interest. It puts more substance behind the OzInverter that 'oztules' started. Everything is possible, just give me time. 3 HughP's 3.7m Wind T's (14 years). 5kW PV on 3 Trackers, (10 yrs). 21kW PV AC coupled SH GTI's. OzInverter created Grid. 1300ah 48v. |

||||

| DaveP68 Senior Member Joined: 25/11/2014 Location: New ZealandPosts: 292 |

Hi Clockmanfr Good work and this stuff is really sparking new lines of discovery and interest from both of you. Thanks for all your contributions so far, including Bruce. Until I get a wind turbine up & running permanently (current location not suitable) will be limited to getting more efficient power extraction per RPM from F&P stators. Got some more reading to do on the 'Fieldlines' forum. Cheers David There are realities if you do not accept, will lead to frustration because you will be spending time on wrong assumptions and the results cannot follow! The Dunning Kruger Effect :) |

||||