|

|

Forum Index : Windmills : F&P stator correct load matching.

| Page 1 of 2 |

|||||

| Author | Message | ||||

| DaveP68 Senior Member Joined: 25/11/2014 Location: New ZealandPosts: 292 |

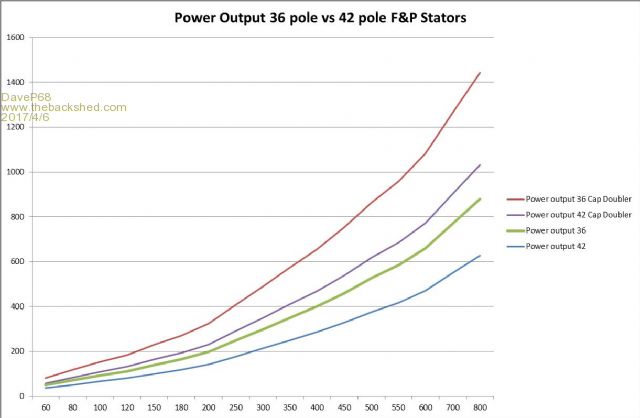

After completing 18 moths of comprehensive testing on all types of F&P stators I now have a full understanding of how to correctly load match them over their operating RPM range. It all comes down to a phrase I've stated on this site twice before 'Load Adaptive Impedance Matching'. What this means in "practical terms" is all of these F&P stators want to put out constant current but variable voltage proportional to RPM in order to maximize their output potential. The strength of the magnetic field determines the optimum fixed current (changes with wire size 0.6 mm vs 0.8 mm vs 1 mm). Then the voltage range is directly proportional to the operating RPM (Again changes wire size 0.6 mm vs 0.8 mm vs 1 mm). If we have no load (open circuit) the stator voltage increases in proportion to the RPM. If the stator is run into a short circuit then we can reach the maximum current output with only a few RPM. This creates a problem when a stator is directly connected to a battery to charge it, as when the terminal voltage of the battery is reached only the current can then increase. I have seen quotes on this site that state that you can't get anymore than 400 W from a single stator. This is the reason why that limit is always reached when directly connected to a battery. Please refer to the graph below showing correct load matching (MPPT) vs direct connection to a battery.  So a single F&P stator has the potential to output far more than 400 W of power. In one of my setups using a specially modified "Capacitor Doubler" I got 720 W at around 500 RPM into a 48 VDC battery. We can break free of this 400 W mythical limit by using some simple circuitry. I'm not saying it can only be done with complex electronic MPPT inverters. In summery these stators like to be matched to a load which increases in impedance with a increase in RPM which allows the voltage to increase at the proportional rate. The capacitor doubler circuit set up correctly helps a lot but it to has it's limitations. Refer to the table below for how MPPT actually works on these stators. Please note no reference is made to RPM.  Having done most of my testing with 36 pole copper stators with black rotor caps I find them the best. That is due to them being 'Factor Decogged' and having 12 poles per phase they can be re wired into more combinations 1x 12p, 2x 6p, 3x 4p, 4x 3p, 6x 2p & 12x 1p. The 42 pole stator can only be wired into 1x 14p, 2x 7p, 7x 2p, 14x 1p. With the above conditions met the 36 pole copper stator can output 41% more power than a 42 pole 60s & 80s and 47 % more than a 100s for the same RPM. I'm not saying the 42 pole stator are no good, just pointing out their limitations as they are after all older older technology. It's a good thing to embrace progress as when the 42 pole stator where in production we lived in a world with no smart phones :) David There are realities if you do not accept, will lead to frustration because you will be spending time on wrong assumptions and the results cannot follow! The Dunning Kruger Effect :) |

||||

| greybeard Senior Member Joined: 04/01/2010 Location: AustraliaPosts: 161 |

Interesting. How would you work out what sort of max power you could draw and what sort of duty cycle it would support at that power? Or are more experiments in order :) |

||||

| DaveP68 Senior Member Joined: 25/11/2014 Location: New ZealandPosts: 292 |

Hi, a bit of an open ended question. If a wind turbine is involved it comes down to what the expected maximum RPM will be. From there I can now easily calculate to the nearest 2% of what the maximum power can be extracted from a single stator. To get a smother power curve from low to high RPM without using MPPT can done with a Dual staggered stator setup. This is due to only low power levels can be extracted in low RPM from light winds. The first stator will be set up to cut in at say 80 RPM on a 48 VDC battery. This stators output max will be limited to 350 to 400 W. The second stator can then be setup for a much higher cut in RPM (~250) but have a maximum output of 700 to 800 W around 500 to 570 peak RPM of Wind Turbine. Add another high power stator setup the same as the second one if you think more power can be extracted from the blades at maximum RPM. These number are just examples what is possible, but are achievable in real world if the correct setup conditions are met. Check out the following link of a micro hydro system using Four 36 pole stators with Black rotor caps each running around 1600 RPM producing 2 kW per unit with total combined output of 8 kW. That is 1.2 W per RPM, so they are all correctly load matched into the two Solar MPPT Grid Tie Inverters in my opinion.. 8 kW powerspout micro hydro system by TAS Energy & Heating Don't worry about the duty cycle once you've seen that hydro set up... David There are realities if you do not accept, will lead to frustration because you will be spending time on wrong assumptions and the results cannot follow! The Dunning Kruger Effect :) |

||||

| flc1 Senior Member Joined: 20/11/2011 Location: New ZealandPosts: 242 |

well done Dave,end of story  |

||||

| DaveP68 Senior Member Joined: 25/11/2014 Location: New ZealandPosts: 292 |

Well summed up Fred, as there are the non believers on this site that think it was a waste of time for me to test these stators into a resistive load! Well it's me that's now going to have the last laugh, as the data shows that I'm 100% correct. One bold statement to make, but I have a huge advantage having a connection with Fisher & Paykel up to Company Board level. After all I know people who worked on the design and development of the end product. That counts for a lot! Hope that your plans for modifying your current wind turbine with new blades are come along nicely. Cheers David There are realities if you do not accept, will lead to frustration because you will be spending time on wrong assumptions and the results cannot follow! The Dunning Kruger Effect :) |

||||

fillm Guru Joined: 10/02/2007 Location: AustraliaPosts: 730 |

Dave, well "Bold" is the word , we dumb ole aussies can only aspire to follow the standards of your F&P Royalty status..... being that is self bestowed. I am not sure what you mean by " That Counts for a lot " ... A lot of What ?? Really that can be said for any / all wind turbine PMA's or just power generation as a whole , ..... But what is the 'Load Adaptive Impedance Matching' where do I get one of these? May-be It's down in the South Island in Middle Earth  Are you going to let us in on the "Specially Modified " because as far as my testing has showed is 12% is where it generally stands which is in line with the increase in flux less the frequency. What happened to the Trippler ? Why not show a 42 pole as an MPPT into the 'Load Adaptive Impedance Matching' Its almost like a bubble , these outputs just keep getting better and better, from 40% to 47% ...... in a week or so it will be cracking 100% . Yes exactly .."IF" .. wind is in excess of 10m/s (36klm) ... NZ has a good resource of that but in reality when you look at the average that is the target zone and where all 42 & 36 become equal given the same blades physical design etc . You have the Blades , you have the Black Rotors, build yourself a wind turbine with all the electrical and electronic knowledge and with that build your MPPT high voltage Buck Boost Load matched system.... Whatever it is . Or into a Power Jack GTI which could be feed back into a off grid system and through the H Bridge for a few more watts for the big wind moments . I am sure you could easily design and build a data logging system then you will have some real world experience to share rather than hypotheticals. But the reality is virtually 99% of wind systems are simple - Turbine - Charge Control - Dump Load - Battery 48V / 24V / 12v So did some tests on your Cap Calc Recommendations - Stator 6x2P 1600uF AC Cap Dblr , not sure if you want the results.. That's a 10A gauge from the dblr into Lithium ... and its also data logged  In reality to " Show and Tell" the big numbers you claim is also driven by high RPMs High Volts into loads that are not in line with normal simple systems. PhillM ...Oz Wind Engineering..Wind Turbine Kits 500W - 5000W ~ F&P Dual Kits ~ GOE222Blades- Voltage Control Parts ------- Tower kits |

||||

| flc1 Senior Member Joined: 20/11/2011 Location: New ZealandPosts: 242 |

Phill, David is simply showing what is possible to acheive with an f n p, Given that he has trained and worked in the feild of electrical engeneering,rf, and that he works with these f n p stators every day,I don't have problem accepting what he says as being correct. I have advised him not to publish anything on here unless he is sure that it is correct,he informs me that he verifys everything with testing before hand. David has publised on here formulas for everybody to use to work all this info out for themselfs,I don't really understand alot of what he says at first,but its not my trade and Im not loseing any sleep over it. Would I be correct if I said that your upset because its not you that is publising all this info? because you don't understand electronics and electrical math like David does? Fred |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

David has gained some really deep and valuable insights into all this. Wind turbines are a particularly difficult beast to match into any particular type of load over a wide range of wind speeds. Living in the suburbs, makes any type of wind turbine not really a possible or practical project for me. So I have no practical experience, only many ideas. As an electronic engineer I can see what needs to be done fairly clearly. The capacitor voltage multiplier is certainly an interesting tool, and if applied correctly may give some very worthwhile gains. But its a very difficult technique to master and deserves better than just a bit of random trial and error experimentation. I very much doubt if any feedback type of MPPT system will work particularly well in typically variable windy conditions, although it might work fairly well in a very steady on shore breeze. A much better idea would be a feed forward system. The basic concept is to measure wind speed with an anemometer quite independently of the main wind turbine, and use the output of that to modify the matching between turbine and load in a predictable way. Just as an oversimplified example, we take the output from out anemometer and determine what wind speed range we are currently in. Say six wind speed ranges A, B, C, D , E, and F for example. Then we use that to adjust our wind turbine loading by any one of several different methods in six discrete steps, based on previous data logging and experience. If its gusting from between speed ranges B to D, the loading on the machine can be instantly stepped up or down, before rotor rpm significantly changes. Response should be very fast, and it can never surge, bog or become unstable. This could all be done a great many ways using relays, capacitor banks, transformers with selected voltage tappings. Or a PWM switching power supply with duty cycle stepped up and down by a microcontroller to preset known best duty cycle settings for each wind speed range. The secret is its NOT a feedback system. Once you know that at wind speed X setting five correctly loads the turbine, it switches to setting 5 every time the wind speed passes through X. Switching is instantaneous, it does not wait to measure turbine rpm or output current. You just need to initially tweak it so at wind speed X you try load settings 4, 5, and 6 and discover 5 is the best. Cheers, Tony. |

||||

| DaveP68 Senior Member Joined: 25/11/2014 Location: New ZealandPosts: 292 |

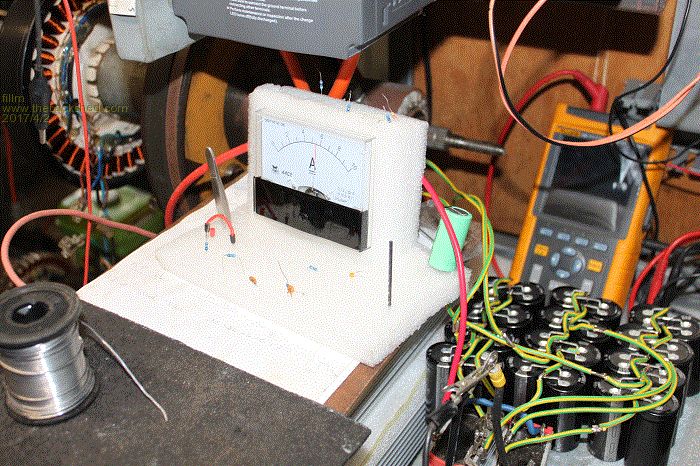

Hi Warpspeed & Fred Thanks for understanding where I'm coming from, as currently I'm unable to put up a wind turbine up in suburbia which I have stated on here in the past. There is a future plan to get a Rural property down the track, hence why I brought some GOE 222 blades recently. Yes I'll admit to Phill that a lot of my testing has been done at higher voltages to date. Due to him getting the low readings, have set up a stator with a new "Capacitor Doubler" on a 36 pole 4x 3p Delta into a load and got 700 W @ 427 RPM. That is 1.64 W per RPM. That is an additional 17 % more power than I got before. Refer to the Photo of my crude setup which isn't as tidy as Phill's.  The capacitors are 280 uF AC (2x 560 uf 250 VDC). Voltage was 87.5 Volts at 8 Amps. Fred has a 45 - 90 VDC input Grid Tie Inverter so that is why I did it in that configuration to prove it would be compatible for 1 of three different stators he plans to put on his new Wind Turbine build. Yes Phill there was an error in the calculation putting the capacitor value at 3x what it should be. Yes we all can make the odd mistake, but in this case it lead me to getting even more power than before! So please try the test again with the same stator this time using any value from 400 to 560 uf AC capacitors. Depending on what capacitors of that size you have on hand and report back with results. Calculation is for 560 uf so use that value if you have them or just under that. There are no errors in my other tests results when not using the "Capacitor Doubler". Phill think I've worked out the set up of your F&P dual. Is it a 100s factory standard star with capacitors of 200 uf AC for the doubler and second stator an 80s re wired 7x 2p Star using 400 uf capacitors in the other doubler? This gives a predicted total output of 850 W for best load match into 48 VDC battery system. The stator resistance for a 80s 7x 2p star is 0.257 ohms vs a 36 pole copper 6x 2p Delta is 0.296 ohms. That is only 0.04 ohms difference. I don't try to work out wire cross section, as it's the final resistance that matters most once the stator has been rewired. The black rotor cap having 40% more magnetic strength is why they can produce that extra power for the very same RPM correctly load matched. Have done some other testing on a 100s Delta with different capacitor doubler, this time with 135 uf AC capacitors and got 543 W @ 455 RPM. The other readings of interest to Phill are 59 VDC at 9.2 Amps. Reason I did the test on that setup is that I didn't spend lots of time re wiring an 80s into 7x 2p. Yes the 42 pole stators can put a bit more power out than I got before due having the corrected capacitor values in the capacitor doubler, now that I've fixed the error in the formula. Here's a graph with revised output data 36 with black rotor cap vs 42 poles.  There are realities if you do not accept, will lead to frustration because you will be spending time on wrong assumptions and the results cannot follow! The Dunning Kruger Effect :) |

||||

| DaveP68 Senior Member Joined: 25/11/2014 Location: New ZealandPosts: 292 |

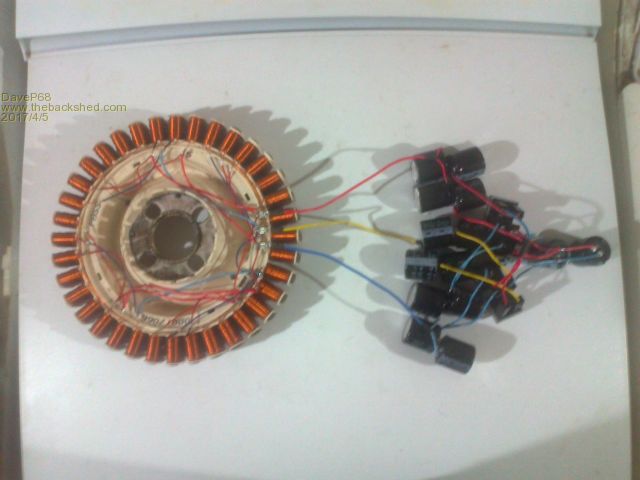

An update on this topic, is that I've re wired a 36 pole copper to 6x 2p Delta with a black rotor cap. Correctly load matched via capacitor doubler confirmed what I've stated before that it can output 708 W @ 430 RPM into a battery 59 VDC at 12 Amps. The capacitor values ended up close to what I recalculated at 600 uf AC, but 560 uf also outputs about 10 W less at same RPM. Phill are you still surprised? Or now except that the 36 pole copper stator with the black rotor cap is just a better stator. Here is a photo of the finished stator re wire (note the coloured coded wiring). It looks like a birds nest but works as predicted. Yes they can be a bit harder to re wire with 0.6 mm conductor size and goes to show that wire diameter doesn't limit the current. I only use Delta mode which produces more current, but less voltage. Please refer to my topic on F&P stator wire diameter as the extracted power output is a bit better on 0.6 mm stators. There are realities if you do not accept, will lead to frustration because you will be spending time on wrong assumptions and the results cannot follow! The Dunning Kruger Effect :) |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

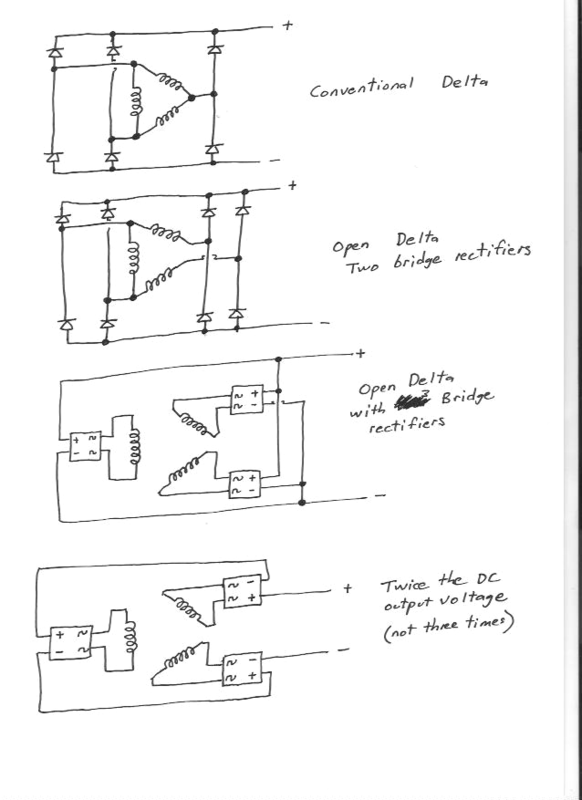

Delta connection does have one potential problem, in that if the three waveforms are not very pure distortion free sine waves, and exactly 120 degrees apart there can be circulating currents between the windings that can result in overheating of the windings and loss of output power and efficiency. You can check for this by opening the delta loop and measuring the voltage and circulating current across the break. In a perfect world both voltage and current should read zero. If there is significant power across the break, all that is going to do is heat up your windings for no useful purpose. Commercial alternators are always star connected for that reason, but as you say, Delta can still be very useful because it produces a lower dc output voltage and a higher current from a rectifier. There is a safe way to still use Delta by breaking the delta connections in one place around the closed loop, and using two extra diodes, called "broken delta". Google should find you some references on that. Here are a few variations on three phase rectifiers you might like to try. The fourth circuit produces exactly twice the dc output voltage without requiring capacitors.  Cheers, Tony. |

||||

| DaveP68 Senior Member Joined: 25/11/2014 Location: New ZealandPosts: 292 |

Hi Tony Thanks again for your input and I find it very enlightening as always open to a new way of doing something. Will try out your 3 rectifier configurations and let you know the results. I'm fully aware of the Delta configuration limitation you're referring too. So far have not notice any power drop off when changing from star to delta when doing testing. Here is a close up of the wiring configuration on that 36 pole 6x 2p Delta stator. Note the wire lengths are all the same on connections phase to phase "Red-Blue, Blue-Yellow, Yellow-Red". This keeps every as uniform and/or symmetrical as possible. If there was even a small current flowing when output is open circuit I wold notice it as a form of cogging even at low to medium RPM. Have noticed anything like that so far. I'm still going to take your point on board by opening the delta loop and measuring the voltage and circulating current across the break. Will let you know these results too. Cheers David There are realities if you do not accept, will lead to frustration because you will be spending time on wrong assumptions and the results cannot follow! The Dunning Kruger Effect :) |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

No way of really knowing for sure, but open the loop and see what is there. Then you will know for certain if there is a problem. I have a pretty large three phase transformer here, must be 5Kw to 8Kw, fitted with three 100 Amp bridge rectifiers. I can connect the dc output side those three bridges either all in parallel, or all three in series to get either 30v or 60v dc out. Very useful for testing all kinds of things at high power levels. Don't know if it has any application for wind turbines, but its an interesting way to get a slightly higher output voltage with low ripple. With star connection you get x1.73 the individual phase to neutral voltage. With three rectifiers in series you get x2.0 Cheers, Tony. |

||||

| DaveP68 Senior Member Joined: 25/11/2014 Location: New ZealandPosts: 292 |

Hi Tony Can't think of an application for your high power testing set up, but it seems to have given an insight into these configurations you've outlined with rectifiers. Many thanks for your advice. Did a tests on 60s, 80s & 100s all wired delta. So with an opened loop, measured the voltage and circulating current across the break. Test results all done at 500 RPM are as follows; 60s 36 pole With (black cap) 5.6 VAC open loop. Closed the loop 53 mA circulating current. 60s 42 5.95 VAC open loop. Closed the loop 38 mA circulating current. 80s 42 3.9 VAC open loop. Closed the loop 52 mA circulating current. 100s 42 1.5 VAC open loop. Closed the loop 130 mA circulating current. Now here comes another interesting part. Did same closed loop test with a 100s into a matched load 500 RPM. Got 3.9 Amps AC for 9.15 Amps DC out of the rectifier. This is the amount of AC circulating current under optimum load conditions going through each pole. Did the math for total heat build up under load for all 42 poles which came to 59.3 W. This is about the same as another measurement on a 36 pole delta under load I did a few months ago came to 63 W. Hope this is of interest to you and others as goes to prove not much power being lost. This may due to how I rewire my stators in Delta configuration. More results to follow once I've tried out your alternate rectifier set ups on delta wired stators Cheers David There are realities if you do not accept, will lead to frustration because you will be spending time on wrong assumptions and the results cannot follow! The Dunning Kruger Effect :) |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

Good to know the F&P puts out some good clean three phase. I had no idea what the results would be, but as you are pretty well set up there for testing, it was probably worth looking into. I don't really have a big battery here yet that I can use for testing inverters and various high power switching power supplies, so my big rectifier along with a three phase variac, is my 100+ Amp bench power supply when I need a lot of dc. Cheers, Tony. |

||||

| DaveP68 Senior Member Joined: 25/11/2014 Location: New ZealandPosts: 292 |

That is some serious current, 100+ Amps DC... Personally I don't know why it seems to be just Fred & I on here who have done lots of testing with these newer 36 pole copper stators (don't touch those aluminium ones). Getting 40% more overall power when load matched correctly with black rotor cap has to be a good thing. In my opinion they are just a better all round stator with the black rotor cap. They are factory decogged, so no need to get the angle grinder out to decog those older 42 pole stators. This is why I've published so much data on them, so one day a few may find my results of use. There are realities if you do not accept, will lead to frustration because you will be spending time on wrong assumptions and the results cannot follow! The Dunning Kruger Effect :) |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

There seem to be enough people here with a serious interest in wind turbines, so its all very worthwhile information. Cheers, Tony. |

||||

| DaveP68 Senior Member Joined: 25/11/2014 Location: New ZealandPosts: 292 |

Thanks for your endorsement. Have been challenged a lot on what I'm doing here as you know. Have to say learn't a lot especially over the last 4 months. So what back ground do you have for high power DC testing? There are realities if you do not accept, will lead to frustration because you will be spending time on wrong assumptions and the results cannot follow! The Dunning Kruger Effect :) |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

I am a retired power electronics design engineer. Interested in all kinds of things, but most recently inverters and switching power supplies for off grid. I am attracted to the unusual, often like to try out ideas that come to me that are either (as far as I know) original or otherwise not main stream. Cheers, Tony. |

||||

| DaveP68 Senior Member Joined: 25/11/2014 Location: New ZealandPosts: 292 |

Well we're both on the same page there. Not sure if you have read the old topic Star / Delta Controller ? Dates back to mid August of last year. Have a new approach to this concept using a 36 pole stator 4x 3p Delta but with 2 outputs feeding in 2x capacitor doublers. Each capacitor doublers can then be high speed switched using FET's to put the outputs in series 2x 6p or parallel 4x 3p at a 260 RPM switching point RPM going up or 200 RPM going down. Example; The default state the switched stator is ste to a start up is 2x 4p with o/p's of cap doubler in series and cut in is around 80 - 90 RPM. It's peak current in this mode will be 4.5 Amps. At 260 RPM 4x 3p delta 57 VDC with 6 A ~340 W. Meant time the second stator set up as a 6x 2p delta is cutting in at 260 RPM with same volts with 3-4 Amps. At say a peak of 500 to 550 RPM the current will be at 22 - 24 Amps which could work out to be a power of up to 1250 - 1400 W form a dual stator on a 2.8 - 3 m set of blades. The FET's need to be high power fast switching and very low on resistance, with a make before break switch over so stator doesn't see an open circuit condition. There is a bit more to the switching system than what I've explained here. As the make before break will put the switching stator into a resistive load at change over so things don't get carried away voltage wise. Also the switch back happening at a lower RPM of about 200 RPM using a form of hysteresis. This configuration will provide the best load matching set up to a 48 VDC batter system so no stator goes into saturation. Got some of my new inspiration from what you posted back on 4 April using an a feed forward system with wind speed with an anemometer quite independently of the main wind turbine. What are your thoughts? There are realities if you do not accept, will lead to frustration because you will be spending time on wrong assumptions and the results cannot follow! The Dunning Kruger Effect :) |

||||

| Page 1 of 2 |

|||||