|

|

Forum Index : Windmills : OZ Wind 2.5kW " All Black" Wind Grid Tie

| Author | Message | ||||

fillm Guru Joined: 10/02/2007 Location: AustraliaPosts: 730 |

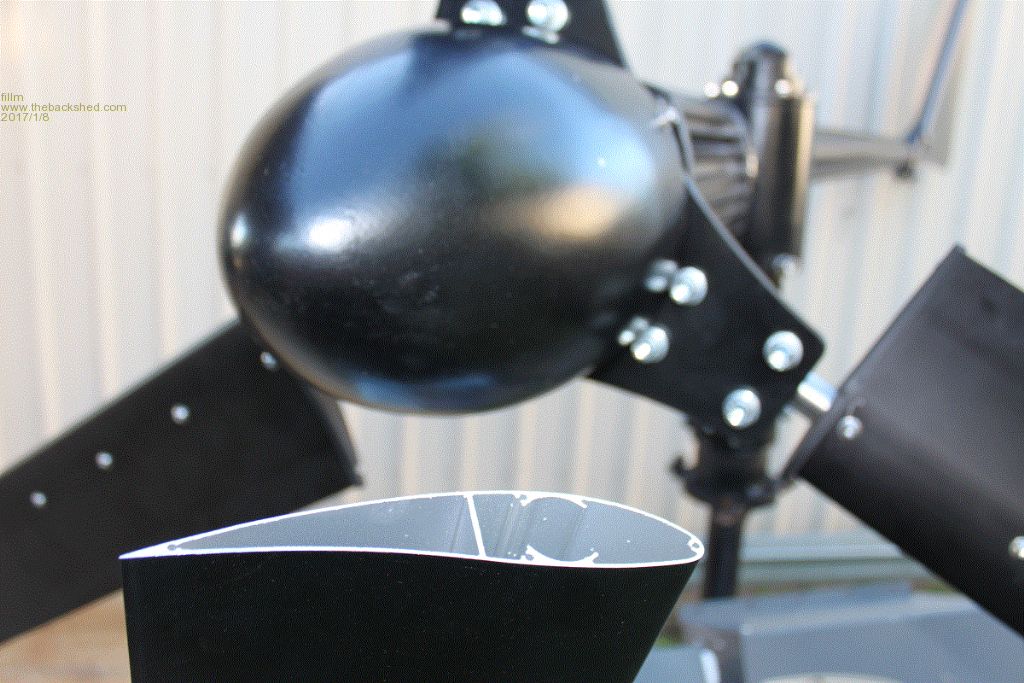

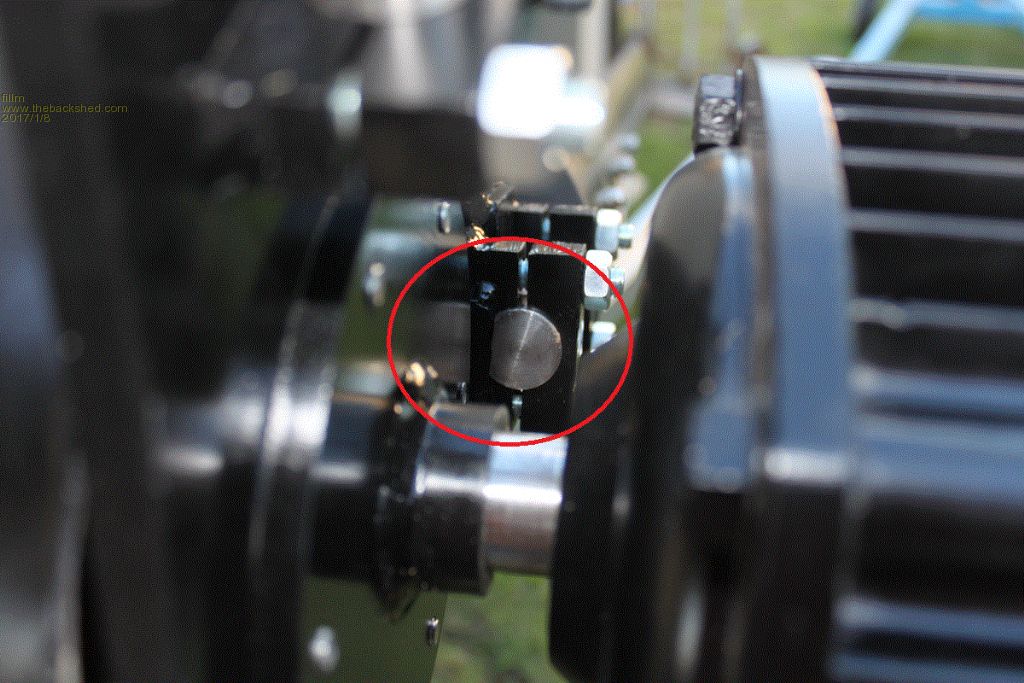

Seeing there is a bit of discussion on Grid Tie Wind here's a couple of pics of one of the turbines that I have just built and finished for a customer. Its a 2.5kW Turbine coupled with the Latronics Turbine controller and their 2.5kw grid tie Inverter. In the last extrusion run of the GOE 222 I decided to get some black anodized so it more or less just all lined up at the time , when I told him about the blades he instantly made the decision to go with a total satin "All Black" paint job, hence the nick name. Now its finished I like it, so I am doing another 2.5kW 48V the same for myself and see how it stacks up against the other OZ Wind 2.5kw units I have in the air. Shunting 5kw into Lithium Batts is no problem.....when I get wind. The blade set is only 3.1m Dia which is a fair bit undersized but the customer is not overly concerned if it underperforms a bit. Its destined to live in the back hills around Melbourne so will get a fair hammering and I predict it will get to max out fairly easy. He wants a wind turbine but no batteries. The set-up when competed and installed by a competent person meets AS/NZ Standards as does the GTI and TC96 meet AS4777. I had the unit in the air for a good 4 months of testing and seeing how well the TC96 works, I trialed adding extra capacitance but it really made its connection and the loading perform worse so all in all it works well enough as is. The PMA is a 180V 2.5kw, so it turns the GTI on at around 105VDC/100 rpm where the GOE likes to kick in and its all said and done by 550rpm . If the grid goes down or the voltage goes over 160-180V power is instantly diverted to the 2.5kw Rated Dump load. He is going to mount it on top of a timber pole which is not the norm, there are 4 x 600mm 50 x 8 chain plates that will mount the turbine mount adapter on the pole that is 200mm Dia at the top. Yep a bit unconventional but he owns enough equipment to easily do the job and maintain it. Yep its guts is just a Chinese Huaya but they are solid and well built with pressed steel nacell / tail tube that I pull apart and add more grease reassemble check Slip Ring alignment to give a boost to their maintainence schedule.  The black anodized GOE222. Anodized or Mill Finish when these are strapped on it's like a completely different turbine compared to the std twisted taper fiberglass blades.  Looking at the back of the blade hub shows how I now mount these blades. the shafts are solid 431S/S that has the same tensile strength as 4140. They extend 30% into the blade and held by 4 x M6 S/S hex bolts . The laser cut blade hubs are 10mm plate with 16mm clamp halves with M10 Hex Bolts  All the blades are match marked to their position and a milled flat allows for perfect realignment for the AOA when reassembled . They are balanced to within 2 grams and tip run out under 5mm so run perfectly smooth.  The PVE2500s come up quite often on the gumtree and ebay and can be picked up quite cheaply , the rest is up to the individual on what is added , wind hydro , batteries, 96V is a bit uncommon but the function is there for battery mode as does the PVE1200 which is 48V. PhillM ...Oz Wind Engineering..Wind Turbine Kits 500W - 5000W ~ F&P Dual Kits ~ GOE222Blades- Voltage Control Parts ------- Tower kits |

||||

| flc1 Senior Member Joined: 20/11/2011 Location: New ZealandPosts: 242 |

Gday Phill, nice looking turbine, with a set of 3 of those blades at 3m diameter,set at 10 degree pitch what sort of max rpm would you expect to get? Fred |

||||

fillm Guru Joined: 10/02/2007 Location: AustraliaPosts: 730 |

Fred, I will have a new guide to send you and Dave and and it will explain a simple mounting method that will still allow to achieve a perfect balanced and aligned set of blades. Its intended to give ideas and or be followed, I do not know peoples skill levels but parts of ( mounting blade to blade stub is a recommended minimum requirement ) how you do the rest is up to you. Later this year I intend to have a new type of hub. As for your question there are to many variable to give even a ball park, but as I have highlighted in Dave's cut in data and also mentioned above, these blades like the cut-in at 90rpm and up to 220.I am not a big supporter of gearing and know you have a geared mill, if its overloaded torque at initial start up then of-course the wind speed required to start rotation is increased. Rpm will always be governed by wind speed, back when I had my the Oz F&P dual up because the torque drops off after approx 500rpm then I have clocked up wards of 750 - 850rpm in 10 ~ 12M/S and have had them in runaway unloaded at probably 1200+.These airfoils defy poeple thinking because of a wide cord at the tip makes them slow.Then in total contrast a 3.5m set can produce 3kW @ under 450rpm . I have had customers successfully build my dual kit and with a 2.8m easily starts in 3-4m/s 2 x 42 pole with no decogging, then will stay running in under 3m/s IF cutin is correctly matched. There is very little power to be had under 3m/s You have not said how your example of 10deg is measured, measuring through the cord center line then its correct but is impossible to easily do in set-up , add 3 deg to that and it can easily be measured on the concave side of the blade 11-13deg. All this will be explained in the guide. Going outside the recommended AOA is a waste of time. PhillM ...Oz Wind Engineering..Wind Turbine Kits 500W - 5000W ~ F&P Dual Kits ~ GOE222Blades- Voltage Control Parts ------- Tower kits |

||||

| flc1 Senior Member Joined: 20/11/2011 Location: New ZealandPosts: 242 |

Thanks for that Phill, my degree measurement is chordline, and your number of about 1200+ runaway rpm was what I was after, gives me some idea of what they are able to do. what I have been after and have managed to do with my current dual turbine , is capture the catabatic and antibatic winds that we have here. hopefully do alot better with your blades Fred |

||||

| DaveP68 Senior Member Joined: 25/11/2014 Location: New ZealandPosts: 292 |

Hi Phill You might boost your potential sales here in NZ with "All Black" in the description. Have to say looks an awesome rig and will look likewise once it's up and flying doing the business. Looking forward to having some of my own GOE222 blades to extract some decent power from. Cheers David There are realities if you do not accept, will lead to frustration because you will be spending time on wrong assumptions and the results cannot follow! The Dunning Kruger Effect :) |

||||

| JimBo911 Senior Member Joined: 26/03/2009 Location: United StatesPosts: 262 |

Hello Phill Long time no chat. Super job on the mill. After seeing it I had to get to you and tell you that my neighbor right done the street from me has a this turbine sitting in his garage. This mill has never really been in service so basically its a new machine. I am defiantly thinking of purchasing it from him and giving it a go especially after seeing what you've done with these machines. Your friend Jim Jim |

||||

fillm Guru Joined: 10/02/2007 Location: AustraliaPosts: 730 |

Hi Jim, Yea long time but obviously you still see what's going on from time to time. Really all I have done with these is bang the GOE Blades on with a well engineered mount and they are a different turbine. If its a Huaya that your neighbor has then grab it if you can get it for the right price. There are a lot of knock offs but Huaya have a pressed steel welded nacelle but all that have the same generator will perform with 2 times + more accumulated power with the GOE's. I gave up on Axial Flux as the GOEs just make them run far to hot in high wind and have come back to the realization that Iron Core in its many forms is the choice for reliability mainly due to the fact that Heat can be dissipated much quicker. Hows the F&P Neo ? is it still in the air ? Anyway good to hear from you again PhillM ...Oz Wind Engineering..Wind Turbine Kits 500W - 5000W ~ F&P Dual Kits ~ GOE222Blades- Voltage Control Parts ------- Tower kits |

||||

| JimBo911 Senior Member Joined: 26/03/2009 Location: United StatesPosts: 262 |

Mr Phill My F&P worked very well I was pleased with it's performance. I no longer fly any mills at this time. I am in a time of transition from my existing home to another. Hopefully in a years time I will at my new place full time. I have been packing my stuff and transporting it there a little at a time. I WILL DEFINITELY BE flying a mill at my new place. My new place sits atop of a bluff. If I had to think of a better place to fly a mill and crank out some serious power I don't think I could do it. This place is a dream come true for a guy like me. Tons of Sun ( PV ) and at certain times of year the wind is something you have to experience. The wind is Awesome! In time I will post pictures of my new place but for now I have to get my Butt there and get started. I do have some experience with the mill my neighbor has in his garage. We (he) did fly the mill for a short time but for one reason or another he gave up. He does not have the shop and machining skills that I have nor dose he have the passion for wind as we do. I could get into the reasons why it dident go well but that is for another time. The mill he has is identical to the one your producing or that's what I believe. I would have to say it's probably an earlier version. It's built heavy that's for sure. At the time it was called an Exmork. I have a ton of pictures of this mill but unfortunately the photos I took are in a large file format difficult to post here. Would it possible to email them some of them to you at your email address for further evaluation etc? Truth be told I have a couple of ideas for two different mills. I do love those GEOS yes I do. After seeing your development of the Huaya I will be buying this machine from him especially after YOU'VE done all the R&D on this setup. Appreciate you return to post to me. Jim Jim |

||||