|

|

Forum Index : Windmills : F&P Stator power O/P MPPT vs battery

| Author | Message | ||||

| DaveP68 Senior Member Joined: 25/11/2014 Location: New ZealandPosts: 292 |

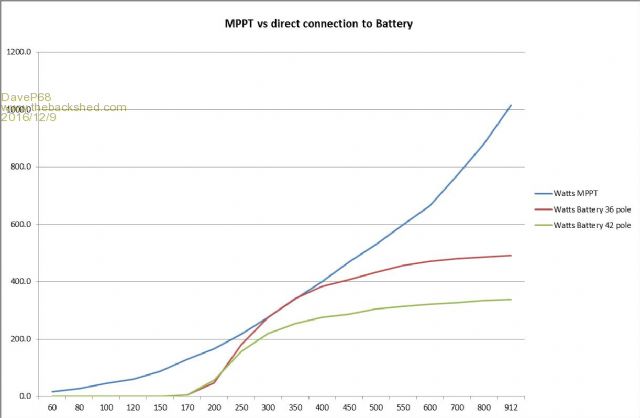

The follow is a graph of power outputs of a 36 pole 48 magnet black rotor cap using MPPT vs both a 36 pole 48 magnet black rotor cap and 42 pole 56 magnet rotor cap directly connected into a 48V battery system. These results speak for themselves, if a form of MPPT is used the maximum power output can be extracted from an F&P stator. Please note the large power output difference between the 36 pole and 42 pole into batteries. This is mostly due to the 20% stronger magnet black rotor cap but also each pole is larger on the 36's that don't saturate as much.  There are realities if you do not accept, will lead to frustration because you will be spending time on wrong assumptions and the results cannot follow! The Dunning Kruger Effect :) |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

Nice. Are there model numbers for the 36 pole stator and the black hub? I've been tempted to have a play with them, but sourcing them via the usual channels ( dump ) can be a problem. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

fillm Guru Joined: 10/02/2007 Location: AustraliaPosts: 730 |

Dave-Glenn, I have a few now for testing and my VFD test bench can go to 1000 rpm , the BIG problem is they are .6 winding and the very best that can be done as " conventional " battery charging is 12x1P and as Dave has shown there is about a 20% better output. Second Big prob is wind turbines do not run @ 1000rpm and in Dave's testing where the blue and red meet is more where power it should be stated at around the 300 - 400 rpm and is clearly the most efficient in both cases. As far as running them straight into a resistor to show 1000W @ 1000 Rpm it is mostly not the norm and really a bit of a mythical figure. An 80S 42 pole as 7x2p Delta will still outperform one of these, or the other option is to rewind the 36 pole in 1mm or more wire. The next problem is the black rotor only come on the Alu winding stators , so obviously it is cheaper to increase flux and on alu to achieve the same result at a lower frequency. So you need to find 2 the Model 3 and Model 4 to make one . I have been also collecting the LG stators rotors of differing sizes to do a whole lot more testing for some projects I have on the back burner and eventually with the intent to offer a solution for mounting as dual / quad ect Buy the looks they will be the bees knees , bigger & steel rotors with .8 copper. windings. Just have not got to it yet because of getting turbines ready for customers. PhillM ...Oz Wind Engineering..Wind Turbine Kits 500W - 5000W ~ F&P Dual Kits ~ GOE222Blades- Voltage Control Parts ------- Tower kits |

||||

| flc1 Senior Member Joined: 20/11/2011 Location: New ZealandPosts: 242 |

Phill, can you explain how a 42 pole .8 f n p will out perform a copper 36pole .6 f n p with a black rotor cap ? the f n p all produce about the same stock standered, untill you fit a black cap to a 36 pole copper, then you get a gain of around 20%, plus the 36 is factory decogged, Im yet to see any home decogging of fnp that matches that,so better performance in low winds, which is what most turbine operate in, so overall,the 36pole copper with black cap is the better fnp for a windturbine, and like most large turbines,to get your 1000 rpm, you simply gear it up,and with mppt why would you want to rewire a stator?,that mppt technology is easily found online and can be fairly cheap and reliable, Davids test showing 1000w simply shows what a fnp can do, with the right setup,or mppt, its no myth, Fred |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

I would not use a MPPT or gearing, but others may. I like to keep it simple, and have no issues with rewiring a stator. While I know it wont achieve the power it could, I'm not that fussed, a windmill without a MPPT or gearing is going to be more trouble free for my applications. Any model numbers, I know I can order the parts from a local white goods supplier, but need a model number. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| flc1 Senior Member Joined: 20/11/2011 Location: New ZealandPosts: 242 |

I meant to say" why would you want to rewind a stator", not rewire. Without useing a mppt charger or inverter you are throwing away alot of power on your fnp, ,but as they say,each to there own,,fnp black rotor number w10199948, fnp copper stator number 8505170, |

||||

| DaveP68 Senior Member Joined: 25/11/2014 Location: New ZealandPosts: 292 |

Hi Glenn Model numbers are not what you are after, as there are 4 versions of say an MW512 but only one has the correct 36 pole copper stator. Product code is best for tracking down these 36 pole copper stators as you could end up with a 42 pole 0.6 mm or a 36 pole aluminium one. Australian product codes are as follows; 93125-A, 93127-A, 93194-A, 93195-A, 93196-A, 93198-A, 93200-A, 93201-A, 93202-A, 93203-A, 93220-A, 93221-A If a Kiwi shipped their machine over from NZ in the last 10 years the product codes all start with 92xxx-A, so pick and choose what market they are made for. For the "black rotor" caps you can go by model numbers, as just pick any machine built in the last 7 years. Some model numbers are as follows; WA55T56MW1, WA55T56GW1, WA65T60MW1, WA65T60GW1, MW513, MW613 etc... Hope this helps. I'm a little biased toward the F&P stators as a PMA, The machine they come from have made me a lot of money of the last 9 years.. Cheers David There are realities if you do not accept, will lead to frustration because you will be spending time on wrong assumptions and the results cannot follow! The Dunning Kruger Effect :) |

||||

| DaveP68 Senior Member Joined: 25/11/2014 Location: New ZealandPosts: 292 |

Hi Phill I would be interested top know the volts/amps output and what the RPM range you tested this 80S 42 pole as 7x2p Delta over? I Need actual results to prove it had a better output than a 36 pole copper with a black rotor cap. The results in the graph posted in this thread are the best I've got so far and there is room for improvement. David There are realities if you do not accept, will lead to frustration because you will be spending time on wrong assumptions and the results cannot follow! The Dunning Kruger Effect :) |

||||

| DaveP68 Senior Member Joined: 25/11/2014 Location: New ZealandPosts: 292 |

For those that are interested here is the full data table that was used to create the MPPT part of the graph. Please note the other configurations in the table which are 2x6c, 3x4c, 4x3c & 6x2c are just scaled results from a 36 pole copper stator wire delta with black rotor cap.  David There are realities if you do not accept, will lead to frustration because you will be spending time on wrong assumptions and the results cannot follow! The Dunning Kruger Effect :) |

||||