|

|

Forum Index : Windmills : 500V MPPT wind charge controller do exist

| Author | Message | ||||

| DaveP68 Senior Member Joined: 25/11/2014 Location: New ZealandPosts: 292 |

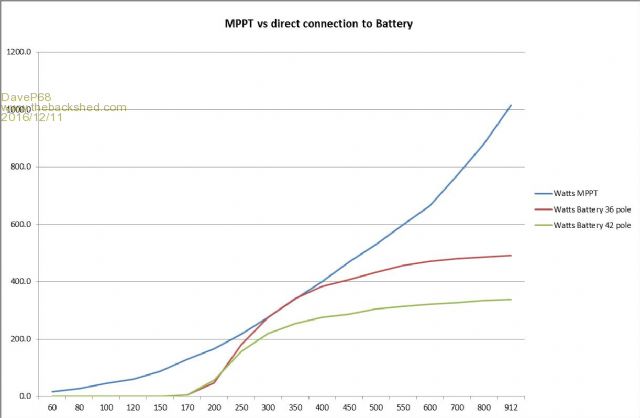

For those who may have seen my graph on how portly an F&P stator performs when directly connected to batteries. I've found an MPPT charge controller that has an input range of 50 - 500V (10 to 1) with charge output in 48V battery system. This is achieved through 'Load Adaptive Impedance Matching' for maximum energy utilization from the wind turbine. To put this in simple terms. No one should ever directly try to charge a flat 12V battery from a 24V battery! There will be so much current flowing, very high potential of an explosive outcome... The controller I found is admittedly a high voltage version, but my point is they exist and input range is 10 to 1 which is ideal. Exactly what a wind turbines want to see electrically. Product is a Tristan MPPT 600V (can use for PV up to 600V wind + hydro to 500 V) There are realities if you do not accept, will lead to frustration because you will be spending time on wrong assumptions and the results cannot follow! The Dunning Kruger Effect :) |

||||

Downwind Guru Joined: 09/09/2009 Location: AustraliaPosts: 2333 |

So you mean to to tell me a device with a 10 to 1 ratio will give more output power than a direct ratio of 1:1 ratio compared to a alternator designed to match a correct give output voltage. (1:1) Seems to be a bandaid fix for a poor design to me. Every time you introduce a factor outside of a 1:1 ratio you introduce losses, so can you explain to me how your losses through electronics are not equated into your final output results. The forum is full of past history claims of the same sort of results. You are trying to take a electronic item developed for solar and apply it to wind energy claiming the same results, and it will not work the same. (albeit it will work) Do you understand how it works with solar? if so you would also understand how it will not work in the same manner with wind energy. Sometimes it just works |

||||

| govertical Guru Joined: 11/12/2008 Location: United StatesPosts: 383 |

https://en.wikipedia.org/wiki/Copper_loss Hi, solar and wind turbine MPPT controllers use different algorithms. Solar MPPT controller are always searching for a duty cycle to allow the most current draw from the panels. Wind turbine MPPT controllers are always searching for a duty cycle that limits copper loss at the PMA stator. just because your a GURU or forum administer does not mean your always correct :) |

||||

| flc1 Senior Member Joined: 20/11/2011 Location: New ZealandPosts: 242 |

Downwind,there are plenty of diffrent types of these controllers online that Davep68 has decribed,some claiming up to 97% efficiancy, don't knock untill you have tryed it, did you consider that maybe the people who have built these know a little bit more about it than you do? |

||||

fillm Guru Joined: 10/02/2007 Location: AustraliaPosts: 730 |

Fred, Can you explain how you have integrated one of these solar MPPT into your system. Have you considered that all this has been put up on the forum many times and yet no-one has ever built and posted info on a Wind MPPT and taken it out of the " What if " stage. It comes down to correctly matching the alternator output to the blade power @ Rpm , then it is a system that is a simple system and easily achievable to all. My limited experience and understanding with MPPT on solar you get a 15 -25 % increase from just a std PWM style control. The voltage range of these 50 - 600V will be more to do with solar strings and ease of connecting for the installer. Although some manufactures do offer a off the shelf Wind Mppt if you go to an Aurora Power One , you can program your own power curve to match TSR. The other are SMA Windy Boy. The other handy thing is the get the name right Product is a Morningstar Tristar MPPT 600V and a Link to where it actually states you can connect wind and hydro systems, also where in the manual Page .... Most times it is just a set of voltage free points or 12V output that can be programed to operate a SSR or Std relay to switch in tern controls a Dump Load. I know dave is a very highly experienced as he has outlined to me, may-be he is the one to crack the mythical MPPT for wind, if not its a very expensive way just to gain very little extra. You both are posting some good info and I think both of you have a lot to offer with these new F&P Black Caps, but inherently they have one big problem with power generation, 0.6mm wire and it plain and simple that is why the whole higher operating voltage is being bought up because with out doing that its a 300 to 400W into a battery. My advice is to re-wind with as big of a wire size as possible and then the additional magnetic flux will significantly give more power at the Battery PhillM ...Oz Wind Engineering..Wind Turbine Kits 500W - 5000W ~ F&P Dual Kits ~ GOE222Blades- Voltage Control Parts ------- Tower kits |

||||

| DaveP68 Senior Member Joined: 25/11/2014 Location: New ZealandPosts: 292 |

Hi Phill I take your point about using a re-wind with as big of a wire size as possible was thinking of trying 0.9 mm as an extra layer can be achieved on 36 pole stator. This is possible due some spare space between pole can be used, giving slightly higher current than 0.8 mm but similar volts out. When a black rotor caps is used, 15 to 20% more power output can be achieved than the arrow head version. No one seems to be trying to use them on here, apart from Fred and I. If 400 W is the limit of what you want per F&P stator, then stick with the simple tried and true methods most have proved to work on here. Just except that you are sacrificing 50% or more of it's potential output power! What my goal on here has always been, is the F&P Stator (36 pole with black rotor cap) has far more potential than that. Just putting some data table/graphs on here to illustrate volts/amps converted to power over a wide RPM range to prove it. I've always known the limitation of directly connecting an F&P stator (1:1 as Downwind puts it) to a battery system. If cheap and easy is what you want that is what you will get. I'm going to try to design a simpler Wind turbine MPPT system to go into batteries than these more expensive off the shelf high power systems. David There are realities if you do not accept, will lead to frustration because you will be spending time on wrong assumptions and the results cannot follow! The Dunning Kruger Effect :) |

||||

| flc1 Senior Member Joined: 20/11/2011 Location: New ZealandPosts: 242 |

Gday phill, I have used the mppt solar inverters on my windturbine earlier but as govertical has explained they are diffrent from windturbine inverter, solar was just too slow for the turbine and I had to rely on a charge controller with dumpload to keep volts down,always eventually ended in a fried inverter in a storm, I now use the mppt windturbine inverters on the wind turbine,they work well, and use the solar mppt on my solar panels, not together ,is that what you wanted to know? One of my mppt solar inverters puts out 980+w from a 800w string of panels regulary,with properly matched panels of course,, I have rewired a .8 stator...well half a stator ,left the other half as standered,2 circuts, but have not tryed it out as at the same time I tryed fitting the black rotor caps and changed 1 of the 36 pole stators wireing to delta, and then took out the 22-60 dc volt wind inverter and fitted a 45-90 volt model,,,,and the output of my turbine doubled,so the higher voltage was the better match for the stator cuts and rpm etc,which are detailed on my turbine page. With the 22-60 volt fitted, the power output would peak well before peak rpm,at about 630w or so , that showed that the satators were saturating,, . I only have a basic understanding of mppt aswell, but I can see that it works well with the f n p, I am currently trying to sorce a 1.5kw mppt windturbine inverter with a input voltage of 40-110v dc... which I beleive will suit my turbine setup better than the current one,and will hopefully have a higher output. I have taken some volt and amp readings and have sent them to Davep68 to produce a graph with ,but he has informed me that I need to send more , too many gaps in readings,,,looking to fit a rpm meter soon,and a more accurate anemometer as my current one is not accurate in high winds..... the graph is coming, thanks for the compliment Phill. |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

One thought that immediately comes to mind is that a wind machine may spend most of its life running at quite low averaged power, with only the occasional very high winds to drive it up to full maximum rated power. So a 500 volt rated machine might actually be running a lot closer to 48 volts for most of its life, and the actual power conversion voltage ratio a lot less than 10:1 flat out. Where you want high efficiency is at average to low wind speeds. If efficiency suffers a bit at flat out maximum, there will be plenty to spare ! But I agree, 1:1 voltage conversion efficiency is always the ideal to aim for if you can do it, but for a wind turbine that sweet spot should probably be based around average wind speed. Cheers, Tony. |

||||

| DaveP68 Senior Member Joined: 25/11/2014 Location: New ZealandPosts: 292 |

What Downwind wrote re "a device with a 10 to 1 ratio will give more output power than a direct ratio of 1:1" is not understanding how the F&P stators are designed to perform. They are what they are, not a poor design as previously stated. Trying for a 1:1 system, knowing that there are whole lot of other variables i.e. wind speed, stator operating voltage over wide RPM range etc etc. Wind under any conditions is variable, so take an average day say 2.5 - 10 m/s, that's a 4 to 1 ratio. With the cubed law of power output over that same range added in that becomes 64 to 1 under ideal conditions looses excluded. The F&P stator |(ALL types) have a very dynamic output voltage range of more than 10:1 with a flatter current curve when used under correct operating conditions. When directly feeding into batteries a higher cut in RPM is required before any current can be extracted at all. Please refer to this graph with MPPT results speaking for themselves...  There are realities if you do not accept, will lead to frustration because you will be spending time on wrong assumptions and the results cannot follow! The Dunning Kruger Effect :) |

||||

| DaveP68 Senior Member Joined: 25/11/2014 Location: New ZealandPosts: 292 |

For those interested, below is a photo of my test set up with Fluke Multimeters + Electronics (Modified F&P Phase 2 Blue Motor Controller). Results recorded were loaded into a table to create the above MPPT graph. Stator 36 pole wired 2x6p Delta with Black rotor cap. Fluke multimeters are showing 201.4V & 5.127A DC respectively giving a peak power output of 1.032 kW @ 912 RPM, so 1000 W can be extracted below 1000 RPM... There are realities if you do not accept, will lead to frustration because you will be spending time on wrong assumptions and the results cannot follow! The Dunning Kruger Effect :) |

||||

| DaveP68 Senior Member Joined: 25/11/2014 Location: New ZealandPosts: 292 |

Forgot about this old post of mine from last year, that I was on the right track re F&P stators wanting a wide input operating voltage range vs RPM :) As I've stated in some other recent posts the F&P stators are current limited in their output. Yes they can be re-wired to produce more current but at the cost of less output voltage at cut in. They want to produce a voltage output that is proportional to their operating RPM range. This of course creates a problem when directly connecting to batteries. This being a home brew (in the back shed) website I'm not trying to discourage any one from doing the direct connection to batteries approach. Capacitor Doublers do help here, giving a better power extraction curve with lower cut in and good current at higher RPM. The point I originally tried to make was there are off the shelf inverters to charge batteries like the TriStar MPPT 600V that capture much more energy from say an F&P stator(s) Another is the Wind Power Grid Tie Inverter is you want to go that way and not have batteries. Someone may still be interested enough to buy one of these products one day and try them out for real. If so please publish the results you get. There are realities if you do not accept, will lead to frustration because you will be spending time on wrong assumptions and the results cannot follow! The Dunning Kruger Effect :) |

||||