|

|

Forum Index : Windmills : Advert-Oz Wind 2kW vs Exmork / Huaya 2kW

| Page 1 of 3 |

|||||

| Author | Message | ||||

fillm Guru Joined: 10/02/2007 Location: AustraliaPosts: 730 |

Hi all, Firstly I will say that www.ozwindengineering.com is now what I do. Wind turbines are my passion and virtually my life. This has been heading this way for sometime now, if putting all this here is a problem because its not " Home made from jam tins" then please complain through the correct procedure. My web site is currently "under construction"). I can share what I am doing here (time permitting) hopefully benefiting some, but in past years and some of the long standing members will remember what has transpired when I Post material like this that sits between, what I am doing and "Soft Advertising" some object for some reason some don't . The thread is Labeled " Advert". From very early days I have contributed here @ TBS, and hopefully helped some, been helped, seen many come and go. Will the future years lean more towards modifications and talk about these Chinese mills instead of building F&P or Axial Flux and keep this forum about alive .... time will tell Who are Huaya and Exmork and a raft of other China dealers. Supposedly Exmork split off from Huaya, but all turbines basically come from the same factory and they all tell you "We are manufacturer you come visit factory" yea sure ,you are going to fly over and see, Its a bit like every salespersons grandma has one of these. Anyway Exmork have changed the tail to a regular furling tail oposed to the tail fin pivot. . But from my info they all come from HUAYA who IS THE manufacturer  ( 2kw sales is approx 1000units per year alone). Huaya do 500w up to 30kW and You can tell the difference with 1 , 2, 2.5, 3 kw HUAYA , they have a 2 piece pressed steel nacell the is welded together, and a nice rolled steel tail tube ...very nice and neat. I have seen some pictures of what look like very rough cast Nacell Housings and horribly copied tail tubes ( 2kw sales is approx 1000units per year alone). Huaya do 500w up to 30kW and You can tell the difference with 1 , 2, 2.5, 3 kw HUAYA , they have a 2 piece pressed steel nacell the is welded together, and a nice rolled steel tail tube ...very nice and neat. I have seen some pictures of what look like very rough cast Nacell Housings and horribly copied tail tubes

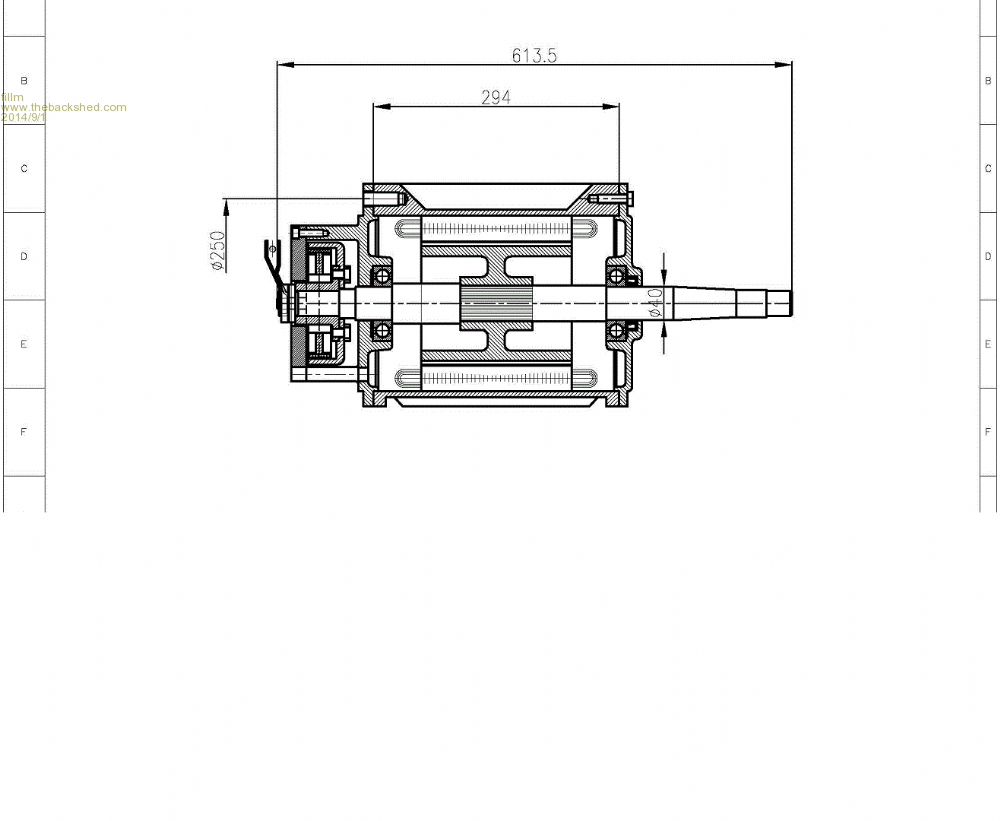

To tell what kW you have these are the generator housing measurements( 1kw 115mm , 2kw-205mm , 2,5 & 3 kw are 250mm with different blade sizes ( generator case only not end plates as well). As usual with Chinese stuff, they almost got it right. With Huaya and Exmork The Nacell & Tail is rock solid but..... Blades

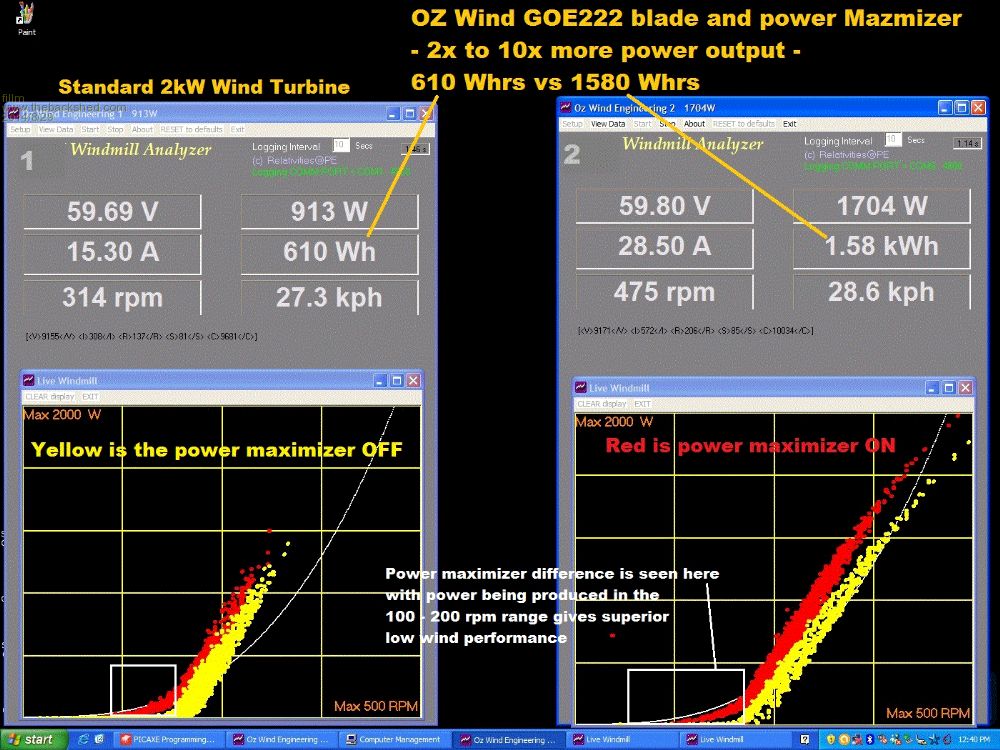

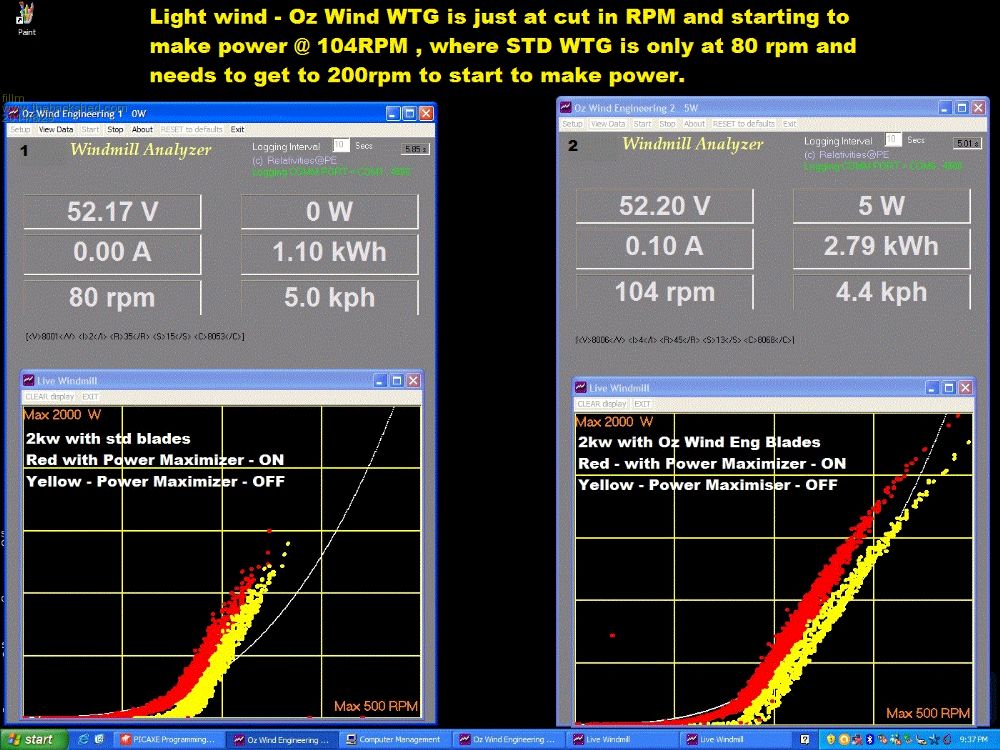

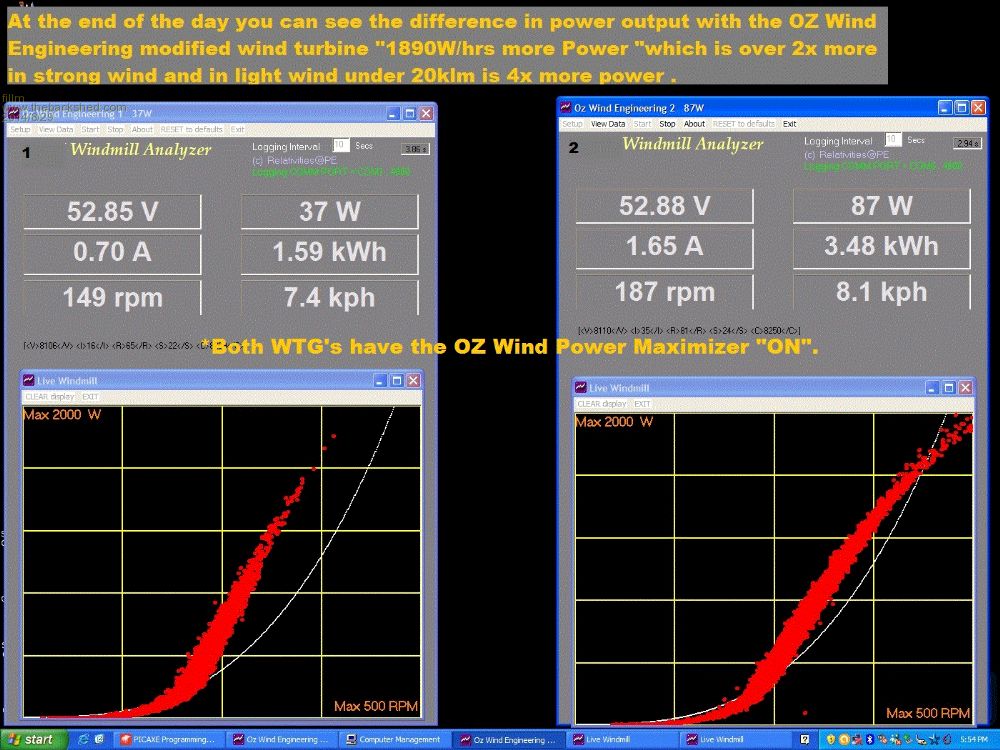

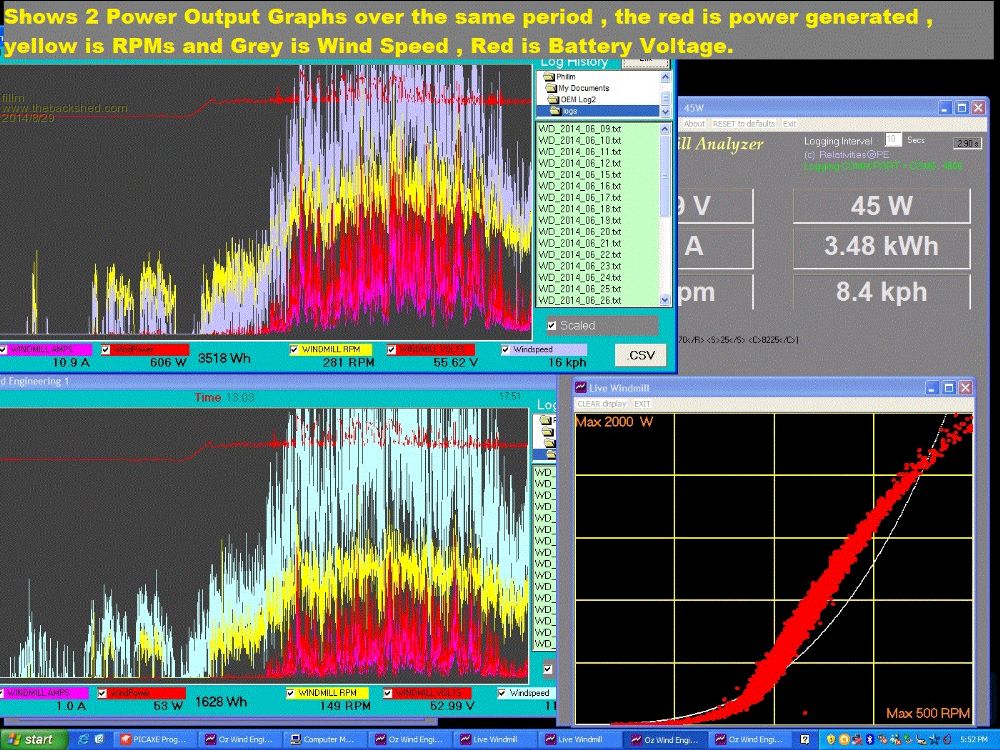

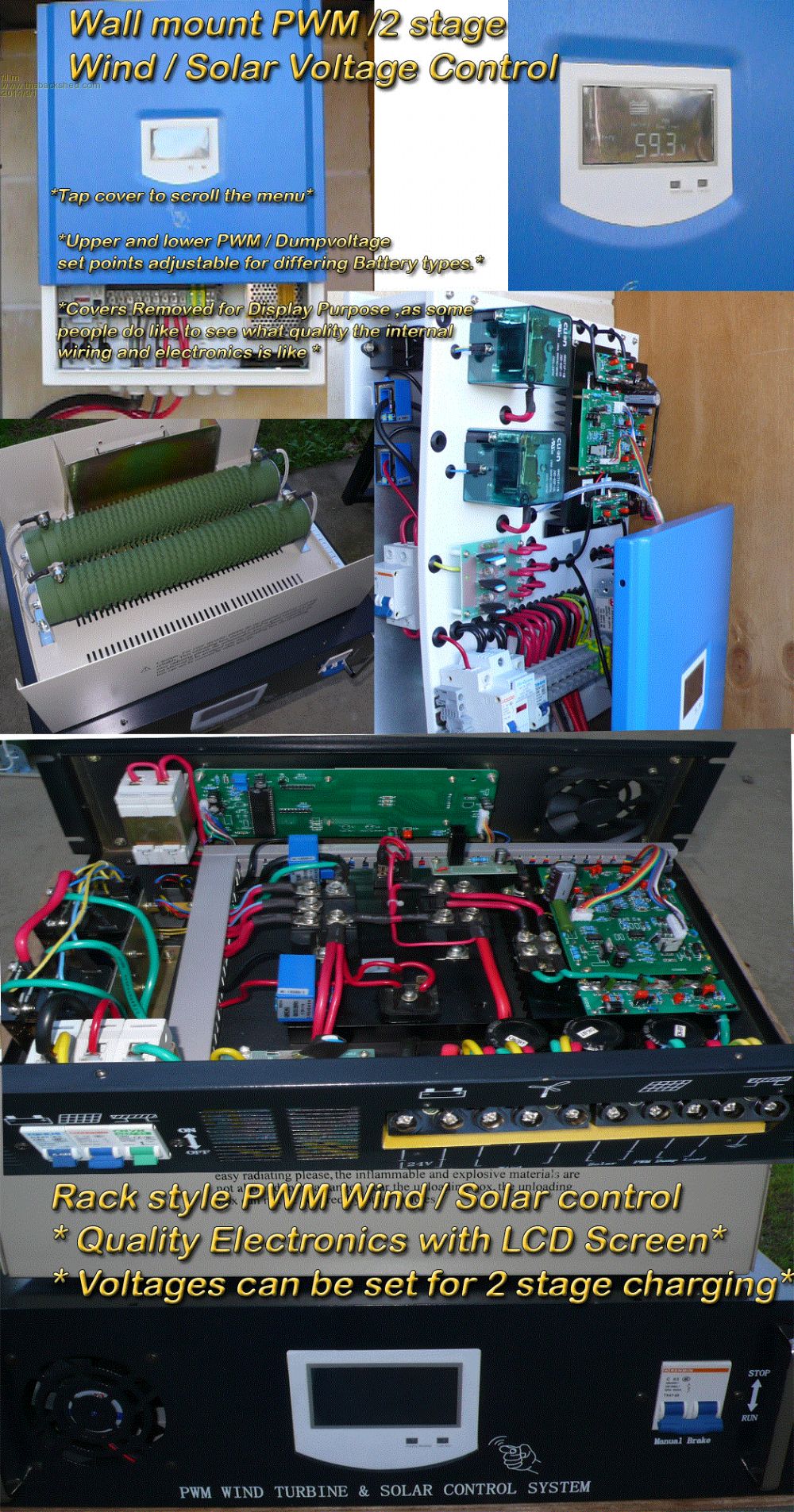

I have also taken on the Huaya Distributorship on the East coast , I now Import them as Nacell and generator, then put the Oz Wind GOE222 blades on a Heavy duty 10mm steel blade 2 piece hub with laser cut 16mm steel clamps, 2 piece meaning you do not need a 10t puller to get it off after 6 months. I have in stock 1kw 24v & 48V and 2kw 48v kits ,Controller +Dump load This is a 2 stage PWM wind solar with LCD screen and I can fault it. PWMs to the 2kw dump load and works extremely well as a battery charger, the 9mtr tower comes with every thing ( guy wires are 8 mm with 16mm turnbuckles. I won't put prices contact me if you want more info there , pictures and vids will be on my web page I will also be selling the as replacement blade hub assemblies separate to people who want better output or the blades have delaminated as they can do being 2 piece and glued , the mount with all these is on a 10 : 1 taper 24.2 to 32.2mm Dia. Bruce, if you want a std blade hub or 2 to experiment with then I have a couple going cheap The Genuine blades look fantastic but it stops there with performance , they can not track the wind and need a howling gale to even come near the rated output . I have 2 2kw/48v flying here being logged 24/7.I have told the factory their blades are poor performers , but they sell shi#laods, so why change . What I see most of the time on light wind days is the Oz Wind 2kW with the GOE Blades spinning while the other is stopped, sometimes it tries to get going in a puff but buy the time it starts the OZ 2kW has been making a some power, and coupled with the Capacitor "Power Maximizer " and with 24/7 logging I always see a reading of 0w/hrs verses 100wh ~ 400Whrs, this all accumulates to a lot of lost power in light wind. This might not seem much but to off-grid people it can mean a lot. Huaya do manufacture a brake for the 3kw turbine its a multi disc cable operated and neatly sits behind and inline with the generator.So the generator end shaft will be different. In my opinion it may make the blades sit to far forward from the pivot/tower and with the std blades it could cause the head to get a constant yaw to the opposite side to the off set, and do 360s like the 2kw, but maybe even worse ... will see when I get one up. This constant yawing to the wrong side happens constantly on the 2kw std, will the bigger ones be further affected with this, I would think so. I call it "Blade Paddling" for the sake of a better word as this is what it appears to do. I have video footage of it and will have that on my web site when that gets going. The GOE being a constant cord do not seem to have this problem and lock on to the wind direction. I am working on furling mods ... I have logged the OZ Wind 2kw pushing out 2.3kw in 40 ~50klm while the other is struggling to get 1.8kW, its constant yawing all over the place just kills it. From what I see these generators can punch out the rated high power 24/7 and not be affected by burn out like AXFX ( unless shorted in high wind to try to stop). I have a set of Oz Wind Blades on a "2kw First Wind" in WA that has been through 140klm hitting 55+A @48v all night on one occasion , this is a high wind zone and the blades were made to 3mtr dia , its has been doing great. Anyway here are some pics and screen shots of the output comparisons, so I'll let the figures say it all. I will say this as well , if you think the numbers are fudged or false , I only wish it were the other way around as then I would not need to build the blade hubs and be able to sell them as a 'top performing wind turbine' a lot of work goes into blade and hub design, building and balancing to make these a top performer.

And here are some images of the Oz Wind Engineering 2kw /48V

PhillM ...Oz Wind Engineering..Wind Turbine Kits 500W - 5000W ~ F&P Dual Kits ~ GOE222Blades- Voltage Control Parts ------- Tower kits |

||||

| brucedownunder2 Guru Joined: 14/09/2005 Location: AustraliaPosts: 1548 |

Good work,,Phill,as usual.. Thanks for the good wishes, I'm anxious to return to playing with my "toys" !. you will do very well with these generators,,,they very solid,but do need a few hours tidying up the slip ring hardware. I replaced the factory rusting hardware with Brass Copper Stainless steel . I've also anti rust the tail boom. Extrusion where it,s showing signs of rust along the folded join . I,ve removed some component boards from inside the controller and sanded back. And antitrust coated the areas where rust was appearing. So. ,enough of the minor glitches. the unit is heavy,strong,big solid windings,good heavy duty 3 phase cabling out of the slip ring dept. and I,m sure with your mods an excellent wind turbine is to be had. I,ll get over to have a cuppa and a chat. As soon as I can ,will call you first,thanks. Bruce Bushboy |

||||

| Jarbar Senior Member Joined: 03/02/2008 Location: AustraliaPosts: 224 |

Absolutely amazing Phill,well done. Jarbar "Creativity is detirmined by the way you hold your tounge".My Father "Your generation will have to correct the problems made by mine".My Grandfather. |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi Phill Finally we have a solid and workable blade and generator combination with Australian know how and backup, while it is fun to do your own thing, from a practical point of view this is the way to go. Verry impressed with the blade performance at low speed as that is what we have most of the time, as for the furling as the Monkey said "that remains to be seen", the Chinese controllers have in the past been disposable items so if you can get that part sorted out it will be an unbeatable combination, from gentle to the roaring forties down south. nice engineering on the new hub it will be a real winner. from a service point of view you could suggest to the makers a parallel shaft and key to make servicing easier as tapers are a pain in the neck to dismantle. All in all, top marks for the machine and for yourself for bringing us a real unit that should last for years. All the best Bob Foolin Around |

||||

fillm Guru Joined: 10/02/2007 Location: AustraliaPosts: 730 |

Hi Bruce , Anthony and Bob, Thankyou for the votes of support........ Bob, I too am convinced that these are a good solid turbine the Nacell & Generator and tail from this turbine manufacturer are very well constructed,and when coupled with the GOE222 blades it is a robust turbine with great output figures that an AXFX mill would struggle to achieve . I have had the 2 x 2kW Turbines flying at my location for a bit over 3mths and in that time they have had some good continuous blows of 40~50 klm pushing 2.3kW that would have had me worried about stator temps with my AXFX designs, if it was F&P they just handle anything and are totally robust but the output does not get to a commercial range of 2kw , 3kw & 5kw . Below is a PICTORIAL view of the controllers. I have selected these types because of their quality over the usual relay type / single voltage dump loads. These will be included as a complete package (Turbine , Controller and Tower) .... as well All will be available separately even to the Nacell / tail / and on etc as spare parts. Anyway, I have been sitting down in front of the computer for days and days learning how to put pictorial information with text overlay together in Photo-shop. Sorry if it looks like an add ... well it is and labeled accordingly ..... Sorry Glenn delete it if you wish. I have put some pictures of the controls and with the lids off as I know some people here are interested and might like to see whats inside. I have had the 48v/2kw PWM Control connected and working for over a month and it has been through a couple of good tests. With 2 x 2kw Turbines flying in high wind there are quite few spare Amps floating around. This turbine does not have the GOE Blades fitted, so it sits in the background. But the controller still sees the overall system battery voltage and reacting to that at 58.6V which is Bulk / Absorb the PWM kicks trying to keep that voltage. Then at 60.2V all turbine power is diverted to the 2kW Load Bank very seemless and all with Mosfets. I have had these fitted with 25 Turn adj Pots for fine tuning Dump voltage set points for different battery types. The big relays that can be seen are not used for control , they keep the unit connected to the DC via the breaker switch , so if it trips or is switched off, the turbine load is diverted to the dump as diversion. With these control unit it can also be connected with 600W of solar , I know that is not much but it can be ordered with a Higher solar input. I like to test everything that I am confident it all works as it should , in saying that I do not get every turbine then test it for 6 months and sell it as a new unit but I do go over each unit and the GOE blade sets will be balanced in my work shop.

PhillM ...Oz Wind Engineering..Wind Turbine Kits 500W - 5000W ~ F&P Dual Kits ~ GOE222Blades- Voltage Control Parts ------- Tower kits |

||||

| brucedownunder2 Guru Joined: 14/09/2005 Location: AustraliaPosts: 1548 |

Thanks Phill , Different controller to mine ,sort of similar components . Dump load , neraly the same , my resistors look brown ,but similar Mine can accept solar as well , but I think 300watts,from memory. I'd like you to post a pic of the furling tail ,mine is just offset and I'm dammed if I know how that little tail fin works ,lol. OK, thanks again Bruce. Bushboy |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi Phill The controller looks very professional in construction and robust, but I must ask if there is a fail safe should the electronic controls go down, as things fail at the square of the number of components and there is quite a few components in that box. Do you have any Pictures of the tower as supplied with the units? I am very interested in the furling as Bruce is because the GEO blades do seem to take extra force to furl once they lock into the wind, a thing I have noticed with mine at nearly 3 meters diameter. They try to override the tail and it is bigger I think than yours. All very interesting though. All the best Bob Foolin Around |

||||

fillm Guru Joined: 10/02/2007 Location: AustraliaPosts: 730 |

Hi Bruce/Bob Bruce - This is how its done with a genuine brake as I mentioned in my post, its is a multidisc type of brake attached to the back of the generator and cable operated . I would suggest you need to think more along the same lines and actuating it at tower base via cable. I would not mount calipers on the gen end , the torque when braking will shear the generator housing , that is why huaya developed this brake type. You could then activate it with you electric linear actuators . I have some here I used in the Liquid resistor .... There are a many ways to do this. Bob , these controls are very well laid out , the wiring neatness is unbelievable. I am pretty sure if it looses main power on the 2x 100A large relays the turbine power is switched direct to the resistors I will be getting a set of pictures done for the tower next. Its heavy duty 3kW Generator showing brake  PhillM ...Oz Wind Engineering..Wind Turbine Kits 500W - 5000W ~ F&P Dual Kits ~ GOE222Blades- Voltage Control Parts ------- Tower kits |

||||

| brucedownunder2 Guru Joined: 14/09/2005 Location: AustraliaPosts: 1548 |

Interesting Phil. I like your assesment of the "Shear Factor" --very important,thanks. I'll probably go the stainless steel yachting cable . with a actuator at the base of the tower,got all that stuff. Pete seems stumped about accessability of the control cable -- From my observation,I've pulled my exmork apart, we can get a clear passage for a 8 mm tube down the dead centre ,through the slip ring assembly. Would need a swivel in that cap at the very top. It's plastic, change it for a brass one ,which then can be silver soldered to a swivel type thingo ,again like we use in yachting gear. I'll get over for a cuppa soon . Bruce Bushboy |

||||

fillm Guru Joined: 10/02/2007 Location: AustraliaPosts: 730 |

Bruce , Sorry I did not notice you replied here , stainless yachting grade stuff is overkill , I like to use Dyeema or Spectra no stretch rope and is all that is required . The big advantage is it will not conduct if it comes into contact with that AC. Dyeema 3mm is rated at 1100kg break strain... Yes .. there is heaps of room in the Slip Ring hole , He is describing what I do with my other mills. PhillM ...Oz Wind Engineering..Wind Turbine Kits 500W - 5000W ~ F&P Dual Kits ~ GOE222Blades- Voltage Control Parts ------- Tower kits |

||||

| domwild Guru Joined: 16/12/2005 Location: AustraliaPosts: 873 |

Phil, I wish you all the best in your business venture and I am sure we all do. Nice work! Like with Glenn's work and others I am green with envy! dom Taxation as a means of achieving prosperity is like a man standing inside a bucket trying to lift himself up. Winston Churchill |

||||

| kitestrings Senior Member Joined: 23/04/2014 Location: United StatesPosts: 102 |

Phil, Best of luck with this, and we look forward to seeing your website. Around here everyone is so enamored with solar that all but the [us] wind-nuts have forgotten it. This works fine for the net-metering masses, but for off-grid applications there's still a lot to be said for a reliable turbine or hybrid system. Plenty of days where we live where the solar contributes very little useful energy production due to shorten winter days, cloud cover, snow, etc...the wind compliments this very nicely. A member of the OP board posted quite a bit about his experience with the GOE222 blade profile. He used wood blades, but posted similar, superior results to some comparative sets. We also used dyneema (4mm) line for furling. Seems to be working very well. Amazingly strong, light-weight and no stretch. Kind regards, ~ks |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi KS We have had some good power generating winds here in Queensland and it is a real thrill to see the amps roll out of the turbines even though they sit still for a lot of the time, there is something about the the spinning blades that is fascinating more so than with the more practical solar that just sits there, as the kids say booooring. In the more windy areas down south the power generated by wind turbines has run many a farm power system in a remote location in the early days before the advent of solar, now the combination makes for a really practical off grid system. Based on Phills figures for the new mills even the lower wind speeds we have up north become useful, I can't wait to get my hands on one of these mills. My experience with using the GEO blades opened my eyes to the low and medium speed power collection of these blades, at least 30% more efficient in lower wind speeds, and as you know even a fence post will generate power in high winds. My little OEM mill is fitted with the Geo blades and has a bent mast from high winds but it still churns out the amps when the wind is right. All the best Bob Foolin Around |

||||

fillm Guru Joined: 10/02/2007 Location: AustraliaPosts: 730 |

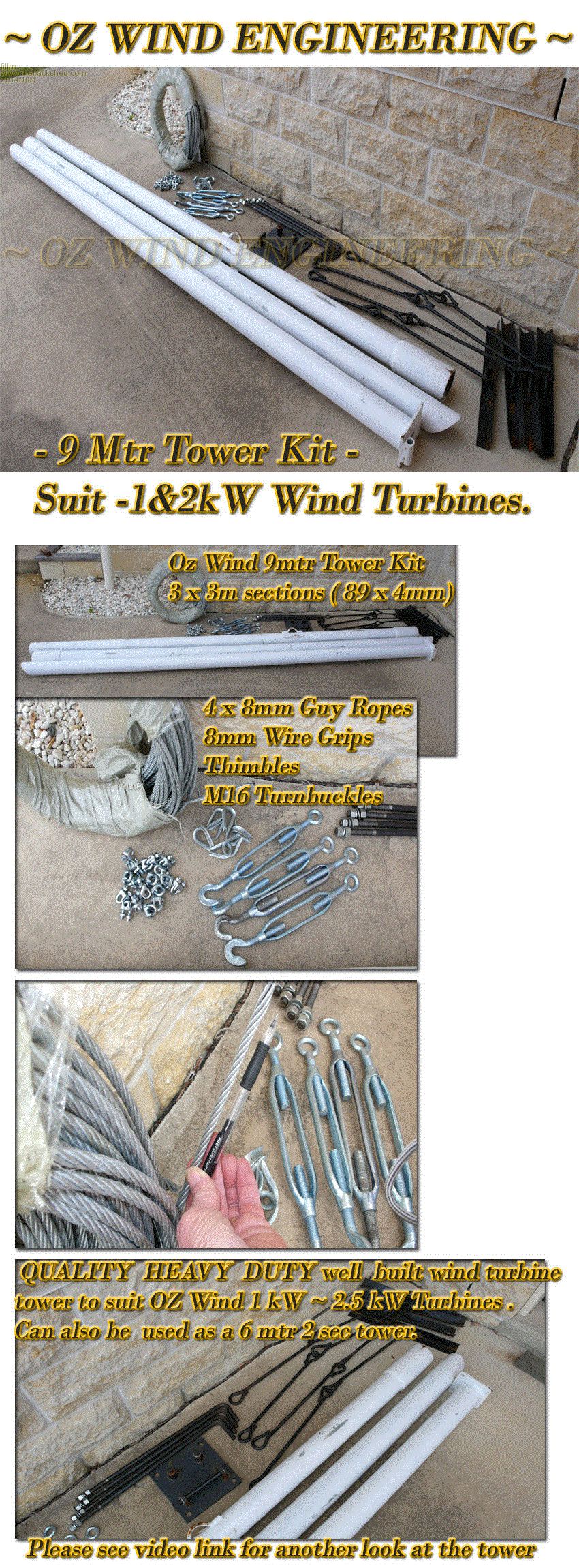

Hi All, I will just finish off this Advert thread with the tower kit that suits these wind turbines , it is 9mtr x 3sections the spigot together with 45deg cuts on the pipes , this is a clever idea that keeps pressure on the slip joint and keeps it in position . The pipe wall is 4mm so it all Heavy Duty . All the parts are designed for strength , the wire guy ropes are 8mm and the turnbuckles 16mm , pretty much everything is supplied with the kit except an easy solution to fit a gin pole for raising and lowering. I have taken this oversite up with huaya and they will be addressing it by using a 76mm pipe joiner that will adapt to the tower base or lower section. This picture is also used in my ebay add, so if you want to see the Video LINK HERE

PhillM ...Oz Wind Engineering..Wind Turbine Kits 500W - 5000W ~ F&P Dual Kits ~ GOE222Blades- Voltage Control Parts ------- Tower kits |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi Phill The tower is very impressive should stand up to our occasional savage blows. It will be interesting to see the gin pole adapter,one thought I had was one of those long throw jacks they use in small floor cranes as they are very reasonably priced and would take a lot of the drama out of raising ang lowering the machine. While you have them in a cooperative mood suggest that they galvanize the base and fittings as I have seen masts come down through corrosion, one of mine and it narrowly missed the kids when they where little, one of the anchor points corroded through and gravity took over. All the best Bob Foolin Around |

||||

| domwild Guru Joined: 16/12/2005 Location: AustraliaPosts: 873 |

Hi, I am also using those turnbuckles with one closed and one open end. What worries me is the possible necessity to wire the open end together so whatever is at the other end does not slip out. Is that possible? Taxation as a means of achieving prosperity is like a man standing inside a bucket trying to lift himself up. Winston Churchill |

||||

| gww1 Regular Member Joined: 14/06/2013 Location: United StatesPosts: 63 |

domwild Make sure you wire the open end, Maby it won't come off till you are raising or lowering but wire is good insurance. gww |

||||

| brucedownunder2 Guru Joined: 14/09/2005 Location: AustraliaPosts: 1548 |

I drill a small,(3mm) hole in the "tang" of the open unded part and then "mouse" the open unded part to stop the guy wire from slipping out while loose. After you have completed your erection and tensioned each individual guy ,I completly "mouse" the turnbuckle . Start by dividing your "moseing wire" ,wrap it around the guy wire a few turns and then start to pass it in a figure-of-eight method thorugh and around the length of the turnbuckle. Tensioning the guys--- a fairly simple ,and reasonable way for our situations is to A hit the guy wire with your open hand , leave your hand on the guy wire and count the return beats in a few seconds. B do this with all , adjusting them C works on a set of equal length guywires,give or take a metre of so .. Bruce Bushboy |

||||

| 4421 Newbie Joined: 17/09/2014 Location: AustraliaPosts: 3 |

Hi, my first post and not one I really wanted to post to be honest. I recommended you to a friend after lurking for a long time, I have had a few fisher and paykel turbine projects and thought my friend could benefit from it because he is renovating and paying off a property and is on a budget. I am no expert on wind/solar but I have lived off grid, one form or another for over a decade now and only have the occassional hiccup here and there. If you read your posts here on f and p, the turbines work and are a good option. After he contacted you, you pretty much put down f and p turbines and gave him a quote for $8000 with your new chinese crap... They might be half decent, I can't really comment but think you have done yourself a disservice and while you still might be a guru, I can't take you seriously. From praising the f and p's to putting them down after you have become a distributor for lucky dragon only makes you look bad sorry. Disappointed and look forward to your reply |

||||

| 4421 Newbie Joined: 17/09/2014 Location: AustraliaPosts: 3 |

Twice you have been logged on and when I log on you disappear. what is your story? You should be able to discuss this with a level head here in the interest of open disclosure! Personally, I think you have lost your roots with statements like this "Home made from jam tins" Isn't this the home made jam tin site of all things wind? Isn't that a bit of an insult to all the diy people here? Being a distributor isn't that much of a big deal. when you open a factory I think statements like that are warranted. |

||||

| Page 1 of 3 |

|||||