|

|

Forum Index : Windmills : picking capacitors

| Author | Message | ||||

| electrondady1 Senior Member Joined: 12/02/2009 Location: CanadaPosts: 208 |

for years i wanted to use a resistance heater in line with a capacitor to act as a load for my windmill(s) but got no were. i could never find out or figure out a formula that would let me get the right farad value. the ac forced me to go with separate heaters for each mill but by rectifying to dc, i would need a battery, a charger controller with a dump load capacity , an inverter and a resistance heater, kind of complex but all those bits act like heaters anyway and i can add more windmills in parallel what sort of battery could take that sort of loading. i have a couple of marine batteries but would they survive very long under such a load? |

||||

Bryan1 Guru Joined: 22/02/2006 Location: AustraliaPosts: 1344 |

Hi Electrondady, Years ago when Dennis was playing with parallel caps in the F&P I came home and tried doing it serial and found the results were a heap more power. Without the caps I was getting 7 amps and with the caps 11 amps. Which was way more than Dennis was getting, anyway as you will see another forum member saw my results and went off on his own bent and that is history in the Australian way. Anyway what I used was 470uf 400 volt caps soldered back to back to make them non polarized and put 3 off each in series. Now as you want to do a resistive load on the F&P with many poles it can work but I have found doing lathe tests on dual axial no better results were produced. I do suppose just trying what you can get hold of some caps cheap or off old boards and put them in a sealed box so if they do let the smoke out no-one or harm any equipment. The only way to do something new is try and DON'T let so-called mates around as stabbing in the back is the norm...... Cheers Bryan |

||||

| anteror Senior Member Joined: 06/10/2009 Location: FinlandPosts: 189 |

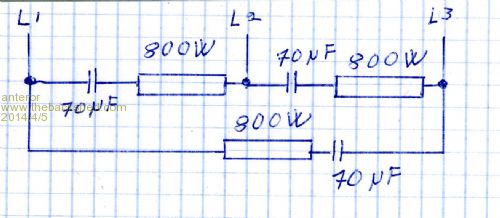

I have tested with my friends a lot of this, to warm with the power from wind with capasitors. That is the best and cheapest way to make controller for warming. Only capasitor type that works and give power enough is so called, reactive power capasitors.(capasitors for power correction). They work perfectly, with wind generator that has 200-(300 max ?!) Ac. You need high voltage wind generator, with this warming system. When the frequency(RPM) and the voltage increases, the more this type of capacitor supplying power to the heating elements. Continuously variable automatic transmission, for wind generator

Perfect for this. Any other capacitor type, will not give enough power through. This; https://www.elfaelektroniikka.fi/elfa3~fi_en/elfa/init.do?it em=65-108-53&toc=19331 Or this; https://www.elfaelektroniikka.fi/elfa3~fi_en/elfa/init.do?it em=65-108-47&toc=19331&name=ac_power_capacitor_100_uf_230_va c,_b32340c2012a730 We have used some electric motor(starting) capasitors that are very cheap, connected parallel to these and with that you can fine-tune the production curve. (if you need to adjust the production curve, when not enough load and too litle resistive load for some reason, or very windy conditions etc) Once you have measured the system right. That is it. This is the best connection to this system. This is for 2kw huayaturbine, for example;

I and my friends have tested and made a lot work with this. We have these here, a lot and workig good ! If you have anything to ask about this, feel free to write me, here on this forum, or with private message. This capacitor system for warming really works and is very cheap, with wind power. -No batteries, or any other power source needed at ALL, to work. -No any moving parts in controller; no relays, no tips. -Can be used to anyplace, to warm.(I have wrote about this a lot and they use these, in Canada, Alaska etc where they used to warm with oil, brought with aeroplane.. before  ) )

etc WE have used this system with 2kw, 2,5kw, 3kw, 5kw and 10kw units. Working voltage 240V; http://www.huayaturbine.com/ -With 2-3Kw units you need just 3 units of these capasitors.(like in the connection picture above.) -With 5kw you need 2-3 parallel.(6-12 capacitors connected parrallel) -With 10kw you need 4-6 parallel.(12-18 capacitors connected parallel) Wind generator working voltage 240V, is the best for this. (300V max !). You can use higher working woltage, but you need higher voltage capasitors and you can find them, but not with this price. Also all the water heating resistors work with 220-240v Ac. You can of course connect them in series etc You need GOOD ! safety factor, for wind power. So, to these capasitors, that can take 440V, I only recommend 220-240V working voltage (300 max, but then must be with parallel 2 units, or with motor capasitors etc, to get enough load, to protect from overvoltage.) Getting warmer, here, in this forum..

PS This my test unit. I have 15Kw electric motor and 20kw frequency changer.. I have made many adapters, to suite any wind generator, with rubber coupling etc We have tested and made many, controllers, with this. All this, with my own money, not to make any busines, but for all of us ! We need OPEN code, for these solutions ! In the picture, 2kw Huayaturbine wind generator in the test bench;

PSS I have some power and voltage curves, if you need. Antero |

||||