|

|

Forum Index : Windmills : Water pumping

| Author | Message | ||||

| raymond thomson Newbie Joined: 19/09/2013 Location: AustraliaPosts: 36 |

Is there a 'table' to show the pumping rate of water for a given windspeed, head etc for various models of Southern Cross Windmills? Links would be appreciated, Thanks. Raymond |

||||

| MOBI Guru Joined: 02/12/2012 Location: AustraliaPosts: 819 |

Hi Raymond, I've never seen a pumping rate table for Southern Cross wind mills but I have seen them for other brands so I expect that a phone call or email to SX mills would get that data. The rotation rate for a wind mill depends largely on the load on the mill and so can not be directly related to wind speed. The simplest thing to do is observe the mill column and count the number of strokes per minute, measure the stroke length and the cubic capacity of the pump. As the pump is usually a "lift" type, the litres per stroke will be constant, so litres per minute can be calculated. If you are pumping up hill, then you will need a device fitted to the top of the mill column called either a stuffing box which is essentially just a packing gland, or a smaller diameter inverted "pump" called a differential head. The former is just a seal to stop the water getting out the top of the column and the latter has small leather "buckets" inside to help force the water up hill. If you have too much load on the system, then there are a number of counter balancing devices that can be fitted to the wheel or the mill stem to assist. David M. |

||||

| raymond thomson Newbie Joined: 19/09/2013 Location: AustraliaPosts: 36 |

Thanks for that David. So keeping the buckets wet is the prime target. Yes I have the differential head with good buckets so now it is a matter of putting it all together. The holes are done so must get onto the legs for the concrete. All getting very exciting now. I will post again as we progress. Raymond |

||||

| yahoo2 Guru Joined: 05/04/2011 Location: AustraliaPosts: 1166 |

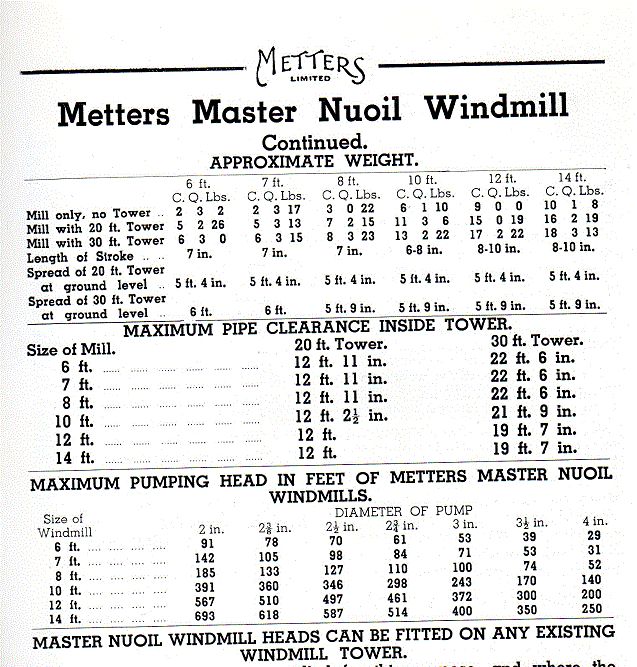

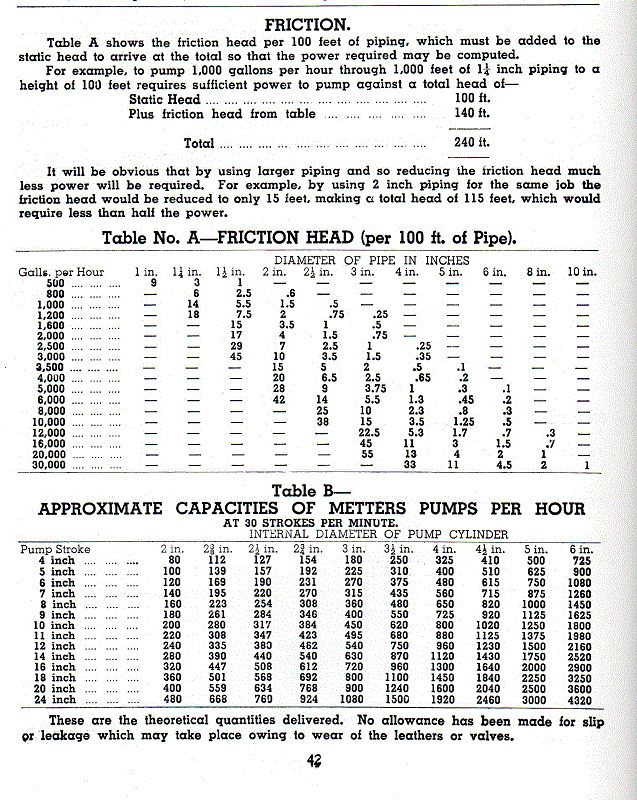

should be enough info here to get you close, you need to know the stroke length that the pump rod travels as a starting point. 30 strokes a minute is no far off, most windmill have the furling set at the factory around that speed or a little faster. edit: obviously non return valves, accumulators, and getting the pump as close in height to the waters surface (if you are pumping from a dam) and a well set up float and foot valve make a lot of difference to the amount of water pumped and the height and distance you can pump it. I'm confused, no wait... maybe I'm not... |

||||

| raymond thomson Newbie Joined: 19/09/2013 Location: AustraliaPosts: 36 |

Thanks for the table. Lots of interesting stuff there, appreciate your help Raymond. |

||||

Downwind Guru Joined: 09/09/2009 Location: AustraliaPosts: 2333 |

Personally i think the table is next to useless for the mill at hand, as where do it show the crank travel or the gearing used for the data presented. Well and fine to post data sheets but it needs to relate to the mill in use. Its a bit like posting data for a brand of wind turbine and expecting it to cover all mills. I worked for a water windmill company about 20 years prior to Mobi owning the same business, and the simple math still applies of pump diameter in relation to stroke length and strokes pre minute = displacement in volume/time. Count the strokes and calculate the volume displaced. Pete. Sometimes it just works |

||||

| raymond thomson Newbie Joined: 19/09/2013 Location: AustraliaPosts: 36 |

Now we are getting to the serious stuff with the Southern Cross windmill! The con-rods are slack in the bearings, (yet to be removed and examined), but there are two other what appear to be white-metalled bearing positions available for the con-rods in the gear wheels. Is this a correct assumption? Are these there in readiness and will they need to be reamed; and will the con-rods probably need re-grinding anyway? It looks like a fairly easy process but I haven't been game to get down and dirty yet without some idea of where I am going, and a map of the potholes. Maybe there is someone out there who has been down this track? My model is a ZC serial Number 13116. My only drawing references are the 'parts list' generated by some companies. Any inputs will be gratefully received Raymond |

||||

Madness Guru Joined: 08/10/2011 Location: AustraliaPosts: 2498 |

Hi Raymond, Are the other positions to change the pumping stroke? Gary There are only 10 types of people in the world: those who understand binary, and those who don't. |

||||

| raymond thomson Newbie Joined: 19/09/2013 Location: AustraliaPosts: 36 |

Thanks Gary. Good question especially as the measured stroke on the down shaft is only 125mm which surprised me. From memory I don't think so, the positions seem equally spaced around the gear wheel. I will check as soon as other commitments allow. Raymond |

||||

nrgcycle Newbie Joined: 09/08/2013 Location: United StatesPosts: 4 |

Good to see that table, it can come in handy for someone finding this page in a search. Anyone happen to have run across another table like it over time? Can't wait to see that one too.  |

||||

| raymond thomson Newbie Joined: 19/09/2013 Location: AustraliaPosts: 36 |

I found another table at www.windmillsareus.com.au showing spome pumping capacity for Iron Man windmill. Also some info at www.vintagewindmillpartslist.com for Z pattern SC windmills. Every bit helps to make the picture complete. Raymond |

||||

| yahoo2 Guru Joined: 05/04/2011 Location: AustraliaPosts: 1166 |

These guys have some exploded parts diagrams, I make my own shafts and bearings, its not a big job If I run into Thommo from Rob's water systems I will ask him if there is any aftermarket gear available for the old southern crosses, he will certainly know. I don't really want to ring and bother him ATM, cos they are snowed under with work commitments. eppumps z model southern cross pdf eppumps windmill parts windmill supplies current IZ model I'm confused, no wait... maybe I'm not... |

||||

| raymond thomson Newbie Joined: 19/09/2013 Location: AustraliaPosts: 36 |

Thanks Gary. Yes the alternate positions are for the stroke length so problem solved-well this one anyway. The pump stroke is now 170mm up from 125mm, 5" to 6.5" and I can only see this as an advantage. With those other inputs I think that I have enough drawings now to complete the project, thanks everyone. Raymond |

||||

Madness Guru Joined: 08/10/2011 Location: AustraliaPosts: 2498 |

Used to machine the parts for those many years ago at Southern Cross. That place is empty now, I would have thought parts would still be made by someone. There are only 10 types of people in the world: those who understand binary, and those who don't. |

||||

| dwyer Guru Joined: 19/09/2005 Location: AustraliaPosts: 574 |

Madness I did work for Southern Cross years ago (I was there) at the same time when TYCO took over and year later they move down the bottom of Toowoomba range however last year Toowoomba foundry went into receivership now empty including metal fabrication at Dalby, Wacol in Brisbane, Melbourne, Adelaide and somewhere else cant remember was all own same badly handle mismanaged Mobs causing more than 500 employee out of work and during the Action sale lot of Machining equipment, Tools, etc and l have brought number of machining at Toowoomba foundry are in very good condition and later went to Dalby Metal fabrication and saw many near new Mig welder approx. 15 off $8000 to $20000 each are sold very cheap and also building ,fabrication large Tanks and other work was left unfinished and l was sad & heart breaking to see this happen including Toowoomba foundry close and building was sold to Bunning warehouse some weeks ago l believe Toowoomba Foundry can be save as they did had lot of work coming in but unfortunately l can't make any comment.  Madness are you in Toowoomba area? Madness are you in Toowoomba area?

Dwyer the bush |

||||

Madness Guru Joined: 08/10/2011 Location: AustraliaPosts: 2498 |

I was there long before any of the Tyco stuff you mention. I was bred and born in Toowoomba area, been living at the Sunshine Coast for the last 14 years. I see in another thread you are from Murphys Creek, I used to live up above Ballard on Vayro rd, used to have a Dunlite generator on a 24 metre tower there. My profile picture is that house. There are only 10 types of people in the world: those who understand binary, and those who don't. |

||||

| dwyer Guru Joined: 19/09/2005 Location: AustraliaPosts: 574 |

That is correct as l still at Murphy's Creek and Dunlite generator on a 24 metre tower is still there? as l have living this area for 22 years Dwyer the bushman |

||||

Madness Guru Joined: 08/10/2011 Location: AustraliaPosts: 2498 |

The generator was taken down about 94, it was visible from Murphy's creek road as you went down before crossing the railway line. Power was connected then, it was never very successful there due to turbulence. There are only 10 types of people in the world: those who understand binary, and those who don't. |

||||

| raymond thomson Newbie Joined: 19/09/2013 Location: AustraliaPosts: 36 |

We finally made it! The windmill is up and running thanks to all who contributed information. The raising process was a bit hairy requiring both truck and tractor in tandem because of damp grass. But the legs were exactly on target and all was well. Climbing up to put the oil in was an interesting exercise and not to be repeated too often. The old bore did not perform so the plumbing was re-arranged to suck from the nearby dam. We are in drought conditions and drawing from just a few cm of water but it is working well. I might get the bore attended to when the water table returns to normal but it is very old and a blast of water down it produced a heap of rust so we might stick with the dam water. It has been a great experience and satisfied the objectives of aesthetic appearance, preservation of an Australian icon and of course the practicality of pumping water. Thanks again Raymond |

||||

Madness Guru Joined: 08/10/2011 Location: AustraliaPosts: 2498 |

Water is so crucial to life. Apparently a farmer near where I used to live was using on old percussion drilling rig. He took 13 months to get down 1300 feet with no luck and committed suicide. There are only 10 types of people in the world: those who understand binary, and those who don't. |

||||