| Author |

Message |

JimBo911

Senior Member

Joined: 26/03/2009

Location: United StatesPosts: 262 |

| Posted: 11:08am 30 Jun 2013 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Tech Question about South West Skystream 3.7

Hello to all you mill heads. I think I have a good one for you guys. About three years ago I helped my neighbor install a Southwest Wind Power Skystream 3.7m mill which sits a top of a 75 foot tower.

The mill has been down about eight months or so, fact is I know of two Skystreams that are have not turned a single rpm for some time now.

The Skystream has an on board dynamic braking system and a grid tie inverter as well, thatís right all the electronics are sitting atop the tower not the best idea I am sure! Itís a down wind design mill.

Southwest Wind Power is gone and out of business so going to them for help is out of the question

My neighbor says heís had enough and just wants to rid of it.

When it was in operation I watched the mill operate and I believe the basic design is a good one, itís quiet, well balanced, and is a thing of beauty.

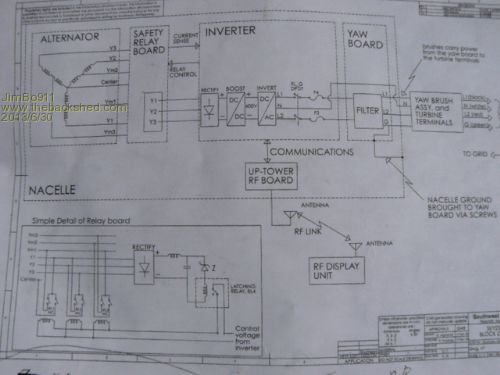

Here is where you guys come in. I canít help thinking that the sweet 2.2 kw slot less neo pma is got to be good for a build of some kind. My knowledge of electronics is limited so to help some of you tech savy guys I have included an schematic so you can take a look at the internal workings etc. Sorry about the quality of the picture.

I know that the mill is still a good mill and the problem falls in the electronics area. I am not concern about fixing the unit what I want (or thinking about doing) to do is by pass the electronics and just bring down the 3 phase electrons and go from there. I am hoping for some info from you guys to see if this is something thatís possible before investing and time into it?

Being that it's a down wind mill one of my biggest concerns would be braking or over speed control.

Thanks a bunch.

Jim |

| |

JimBo911

Senior Member

Joined: 26/03/2009

Location: United StatesPosts: 262 |

| Posted: 11:17am 30 Jun 2013 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

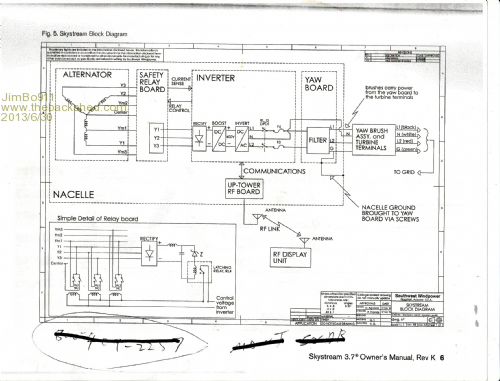

Skystream 3.7

Hoping this image is better.

Thanks again.

Jim

Jim |

| |

Madness

Guru

Joined: 08/10/2011

Location: AustraliaPosts: 2498 |

| Posted: 12:03pm 30 Jun 2013 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Are you planning to use it as a grid tie or to charge DC batteries?

I would be setting it up on a bench so you can turn it by hand. It should start to produce enough voltage to be able to see where the fault is. The fault may be in the safety relay board it may be burnt out relay contracts. If it is in the inverter it would be harder to repair. Also getting it on the bench and turn it you can get an idea of what voltages it produces from the alternator. You may be able to use it with a third party MPPT inverter or charge controller depending on how you plan to use it.

There are only 10 types of people in the world: those who understand binary, and those who don't. |

| |

JimBo911

Senior Member

Joined: 26/03/2009

Location: United StatesPosts: 262 |

| Posted: 12:25pm 30 Jun 2013 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Madness

Not sure as of yet how I would use it. At present I have a battery based system. I know that Midnight Solar sells there Classic MPPT wind charge controllers mated with the Midnight Clipper which keeps the voltage under control.

Truth be told I would just love to get my hands on it and put it on the bench and play with it either way.  The voltage supplied here from the utilty is two legs of 120 volts which of course is 240v. The voltage supplied here from the utilty is two legs of 120 volts which of course is 240v.

Bergy now sells there XL1 ( 1K ) mill with the Midnight MPPT set up.

Thanks

Jim |

| |

Downwind

Guru

Joined: 09/09/2009

Location: AustraliaPosts: 2333 |

| Posted: 06:19pm 30 Jun 2013 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

There might be nothing wrong with the mills, and just how the skystream works, i dont know what the mills are you have, but some skystreams use a system that dumps power with heaters (120 or 240VAC)and there is a built in safety in the mill head that triggers a electronic latch under certain conditions that shuts the mill down to protect it, the only way to release the latch is to lower the mill and manually reset it.(most likely the "Safety relay board")

Its been a while and i dont remember all the details now, although will find out more information, as i know someone who built a retrofit circuit to bring the heaters on earlier to stop the mill from latching up early in certain conditions.

Pete.Edited by Downwind 2013-07-02

Sometimes it just works |

| |

JimBo911

Senior Member

Joined: 26/03/2009

Location: United StatesPosts: 262 |

| Posted: 02:41pm 01 Jul 2013 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Hello Pete

Thanks for your response I will look forward to receiving any and all info that may or may not help with the 3.7 m mill.

I am against the idea of having control boards, invertors, relays etc sitting atop of the tower, just a bad idea all together.

Thanks

Jim |

| |

Downwind

Guru

Joined: 09/09/2009

Location: AustraliaPosts: 2333 |

| Posted: 06:27pm 01 Jul 2013 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

I found out a bit more information, and the first question to ask is ...when the cover of the narcell is removed is there any burnt smell, as they have a habit of burning up the circuit.

If no burnt smell... then it might be still all working.

The relay latch is there to protect the mill and once latched it holds a dead short across the 3 phases, skystreams answer was to supply a new relay board, but the relays can be unlatched with applying 48vdc to a pair of pins, although polarity must be correct.

Its a crap design needing the mill to be lowered and the narcell opened to reset the relays.

To change the mill and remove the inverter and controls from the top of the mill is not so easy as they are designed to put grid voltage down from the mill, and things like slip rings wont handle DCV at high amps or 3 phase AC, as im told they are only a carbon track type slip ring.

The skystream is a noisy mill and they howl or whine something terrible .

Gordon is the person who has worked on these mills not me, so information is only what i remember from his experience with them, i know he developed a circuit that allowed the relays to be reset from the ground by disconnecting the mains power to the mill and reconnecting it again would activate the circuit to reset the relays, without disabling the relay latch protection.

If the mill is not burnt out in the circuit then perhaps i can put you in direct contact with Gordon for better advice, i can only ask for you

Pete.

Sometimes it just works |

| |

JimBo911

Senior Member

Joined: 26/03/2009

Location: United StatesPosts: 262 |

| Posted: 02:50pm 02 Jul 2013 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

"Woooooooo " Pete, your like opening up a Treasure Chest of Information  Got to love that. Got to love that.

Mill still atop the tower so getting a sniff is a bit tough right now but if I get the chance I will definitely use my nose for sure. The info on the slips rings is something I would have never thought of.

I am going to see what I can do to get my hands on this mill, have to see how long the owner can take not seeing his mill spin in a stiff breeze or how long he can hold out before he says (You can have it but you have to get it down.)

I have worked in the construction industrial my entire life and it just so happens I have a friend with a BAD ASS CRANE that owes me a favor.

As far as whining and howling I have watched this mill spin for approximately three years and its always ran quiet thats not to say while charging battiers that it would be the same.

Not sure if asking for Gordons help this early in the game is appropriate but I sure do want to thank you for getting me this far.

For the next week I will be on vacation and where I am going the phone

(internet) service is very poor so you may not here from me till I return.

Thanks a bunch.

Jim R.

Jim |

| |

Downwind

Guru

Joined: 09/09/2009

Location: AustraliaPosts: 2333 |

| Posted: 04:41pm 02 Jul 2013 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

By the sounds of it needing a crane to lower the mill, could well indicate the mill is latched in protect mode, and appears to be a dead mill, because there is noway to reset it from the ground.

If it was burnt out then you would expect to see it flogging around in the wind and making no power, where as latched its brakes full on and it might move slowly in light winds only.

Good luck.

Pete.

Sometimes it just works |

| |

JimBo911

Senior Member

Joined: 26/03/2009

Location: United StatesPosts: 262 |

| Posted: 09:38pm 02 Jul 2013 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Pete your spot on. Its doing just what you've explained.

Thanks again.

Jim |

| |

Downwind

Guru

Joined: 09/09/2009

Location: AustraliaPosts: 2333 |

| Posted: 11:59pm 02 Jul 2013 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

That would seem a possible good deal, if you can get them for removal costs in that case.

Although you would need to modify them to be resettable from the ground or you will be calling upon your mate with the crane more than he would like.

See how you go with doing a deal on the neighbours eye candy / wind vane, and remember it might be shagged, but my guess is its a simple problem / design fault a man like yourself can solve easily with a little help.

I spoke with Gordon, and he said as you are an older forum member and also remembers you, he's happy to have a chat should he be able to help.

In many cases what Gordon has not already been and done, is still what many are yet to workout, when it comes to windmills and solar systems.

You might remember some of his work as member GW@PE and is no longer is a forum member.

We can deal with that when you have the mills in your hot hands.

Pete.

Sometimes it just works |

| |

JimBo911

Senior Member

Joined: 26/03/2009

Location: United StatesPosts: 262 |

| Posted: 12:53am 03 Jul 2013 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Pete

Yes I remember Gordon very well in fact the F&P neo mill I constructed and still flying is modeled after his design.

Thanks again.

Will keep you posted.

Jim

Jim |

| |

anteror

Senior Member

Joined: 06/10/2009

Location: FinlandPosts: 189 |

| Posted: 09:34am 05 Jul 2013 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

We have some Sky.. here in Finland.

DO NOT work !

They are just bullsh*t

Do not buy them.

Antero

Edited by anteror 2013-07-06 |

| |