|

|

Forum Index : Windmills : Can someone explain tail pivot angle?

| Author | Message | ||||

| Digimas Newbie Joined: 24/02/2013 Location: United StatesPosts: 9 |

Hello, Can someone explain the tail pivot angle? I've been looking at the explanation here: http://www.thebackshed.com/windmill/docs/furling.asp but where I'm confused is this part: "The Tail Pivot is just a simple hinge that is angled back and to one side, usually with an angle of about 20 degrees." Why is it "back and to one side", why can't it just be straight back, perpendicular to the plane of the blades? I've also looked at this post: http://www.thebackshed.com/forum/forum_posts.asp?TID=480 but one of the pictures shows both a 45 degree and 20 degree angle. Can someone clarify this for me? Thanks, Digimas |

||||

| Tinker Guru Joined: 07/11/2007 Location: AustraliaPosts: 1904 |

Some time ago I was wondering about that too. Best if you mock up a small hinge with a stick attached and see what happens to the end of the stick (tail blade) as you turn it. First clamp your hinge in a vice with its pivot vertical, when you move the end of the stick it can stop and remain in any position. Now clamp the hinge so its pivot angles aft and try the same. The stick end will raise up (from a horizontal pane) the further from direct aft you move it to one side. Gravity will swing it back now. Then angle the hinge pivot sideways and aft and see what happens. Someone else will explain the exact reason for the side angle no doubt, it has something to do with the precession of the rotating blades I believe. Klaus |

||||

| yahoo2 Guru Joined: 05/04/2011 Location: AustraliaPosts: 1166 |

If you are not a person that can build and visualize something working in your head then a small cardboard and sticky tape model (or thick copper wire)is good practice to develop some skills. You will find that adding the side angle will achieve two major things. It will increase the rate which the tail moves up as the head of the mill comes around, this holds a lot more pressure on the blades to stay straight, this means the mill will face more head on to the wind in lighter conditions and the tail can be lighter therefore more responsive. It will also prevent the tail from laying over as the mill come around. This "laying over" can be a major problem. When the millhead is furling and the tail sticks up, the wind will "see" a partially horizontal surface and be deflecting the tail DOWN, trying to force the mill back into the wind as the windspeed increases, just the opposite of what we want to achieve. So the mill could come out of furl in high winds and keep charging or the more likely option, become unstable and thrash about like it is having a seizure. cheers Yahoo I'm confused, no wait... maybe I'm not... |

||||

| Digimas Newbie Joined: 24/02/2013 Location: United StatesPosts: 9 |

Thanks for the replies thus far. The main point I'd like clarified is how far to the side do you go? "angled back and to one side" the angled back part is straight forward since it's perpendicular from the plane of the blades, but is there a specific angle that would describe the degree of "to the side"? |

||||

| Digimas Newbie Joined: 24/02/2013 Location: United StatesPosts: 9 |

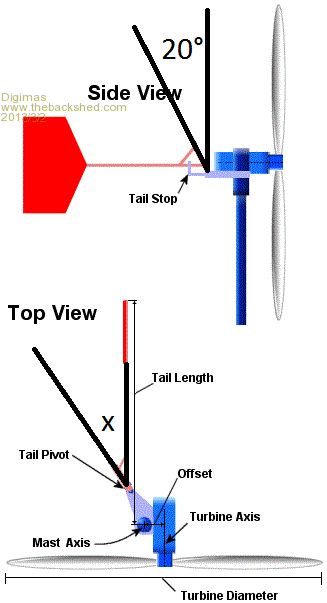

Here's an image illustrating my question. What is the angle x?

|

||||

| yahoo2 Guru Joined: 05/04/2011 Location: AustraliaPosts: 1166 |

No, looking at the side view should be 45 degrees not 20 degrees. The other angle would be looking from the back or front, the tail pivot post will be leaning away from the tower mast 20 degrees from vertical. I would do you a picture but I am late for an appointment. gotta rush, sorry!! I'm confused, no wait... maybe I'm not... |

||||

Downwind Guru Joined: 09/09/2009 Location: AustraliaPosts: 2333 |

A little forum research would bring up a large amount of information in this area. For example in a thread a few weeks back Phil posted this comment........ The thread can be found here. http://www.thebackshed.com/forum/forum_posts.asp?TID=5378&PN =1 Pete. Sometimes it just works |

||||

| Digimas Newbie Joined: 24/02/2013 Location: United StatesPosts: 9 |

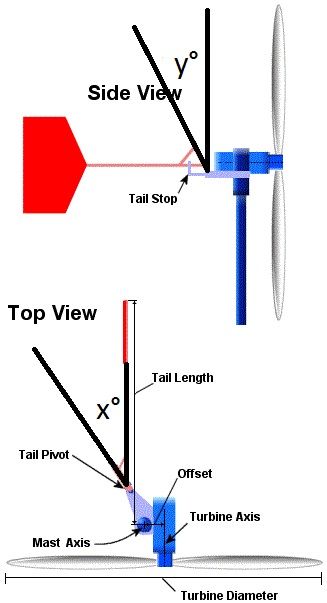

Thanks Pete, I had looked at that post as well but was still confused by which angles Phil was referring to. Just for clarity, could someone fill in the values for x and y in this image?

|

||||

Downwind Guru Joined: 09/09/2009 Location: AustraliaPosts: 2333 |

Y = layback angle (about 2 degrees) X = side angle (about 12-15 degrees) Sometimes it just works |

||||

| Digimas Newbie Joined: 24/02/2013 Location: United StatesPosts: 9 |

Thanks Downwind Can anyone else confirm these numbers? |

||||

Downwind Guru Joined: 09/09/2009 Location: AustraliaPosts: 2333 |

Perhaps you should tell us what type of mill you are referring to and what size mill and any other data about the mill you intend to build, as all these things might change the angles with furling. Pete. Sometimes it just works |

||||

| Digimas Newbie Joined: 24/02/2013 Location: United StatesPosts: 9 |

Type of mill: Wind Turbine Blades I'm using: http://www.ebay.com/itm/360306875654?ssPageName=STRK:MEWNX:I T&_trksid=p3984.m1439.l2649 Generator: http://www.ebay.com/itm/111007312533?ssPageName=STRK:MEWNX:I T&_trksid=p3984.m1439.l2649 Wind speed I want to start furling: 21 mph |

||||

| Digimas Newbie Joined: 24/02/2013 Location: United StatesPosts: 9 |

Can anyone confirm the numbers Pete (Downwind) gave? |

||||

Downwind Guru Joined: 09/09/2009 Location: AustraliaPosts: 2333 |

You gave a link (that dont work) to a DC motor for a generator, and a link (that dont work) to a set of rip off design Air-X blades, Its a tall ask to expect a exact set of furling degrees to suit your intended build, it simply can not be done, other than scratching around in our underpants and pulling a figure of degrees out. So many factors can change the angles required, like tail length, tail weight, yaw bearing off set, weight of alternator, blades used, how many blades used, blade weight, the distance between yaw bearing and blade centre, the distance between yaw bearing and tail pivot, and the list goes on................................. Dont think no one is answering your questions, its just no one has a direct answer to your question, the question is a bit like how long is a piece of string? Your best option is to study up on how furling works and then make a mill to your best understanding, with knowledge of how to make changes, with design allowances to adjust the furl angles, should it not be right first up. There is no blueprint to an exact angle of furl due to the fact every home mill construction is different. Pete. Sometimes it just works |

||||

fillm Guru Joined: 10/02/2007 Location: AustraliaPosts: 730 |

As Pete has said , there are too many factors that all add together to affect Furling , and you just want to be given the perfect furling figures . It took me 2 - 3 years and a lot of different designs to get the furling that I am happy with " For My Mill Designs " and it didn't come from playing with bits of sticky tape and cardboard either. I have mentioned to Glenn a couple of times about the furling guidelines on the home page as people read it and all they see is 20deg and think that is the magic number and go of and build to that and then wonder why its not working . IMO , You can not work out furling on paper. The lay back and side angles you were given was from advice given by me from another thread and are a base line to start with , but you could put a 20kg tail on and it wont furl in a Gale or to lite and it furls in a fly fart , and that is only one FACTOR change, the rest have been outlined previously. You have another option , with that motor you bought and I didn't bother to check the blades but it will need to spin at like crazy rpms to get any sort of output i would think , build it all very strong and don't worry about furling , the output from those is not going to be a lot. PhillM ...Oz Wind Engineering..Wind Turbine Kits 500W - 5000W ~ F&P Dual Kits ~ GOE222Blades- Voltage Control Parts ------- Tower kits |

||||

| Digimas Newbie Joined: 24/02/2013 Location: United StatesPosts: 9 |

Ok, thanks for the advice. Does anyone have any recommendations for wind furling information that I can study up on? I honestly haven't found much online except for the explanation here on thebackshed.com |

||||

| norcold Guru Joined: 06/02/2011 Location: AustraliaPosts: 670 |

Post your question to windempowerment.org. If you follow Hugh and his build to a tee you will achieve the results you seek. Otherwise it is a matter of experiment. My first mill(200w Chinese) furled to early, a 9" length extension to the tail solved that problem and keeps the mill tracking the wind until gusts in excess of 35km/hr cut in the furling. My experience tells me you will get a compromise between steady tracking and furling until you get the mill high enough to get it out of turbulent air. To get it high enough to achieve this is dependant on site conditions. That is determined on your resources and the amount you are prepared to pay to get that height above turbulence. After some experience you will than understand and appreciate the info this 4M has offered. There is no magic formula to my knowledge, if you should find it, all on this 4M would love you to share it with us. We come from the land downunder. Vic |

||||

| Digimas Newbie Joined: 24/02/2013 Location: United StatesPosts: 9 |

Does anyone else have any recommendations for furling information either online or print? |

||||

Downwind Guru Joined: 09/09/2009 Location: AustraliaPosts: 2333 |

Digimas When will you work out its not that no one will share information or links with you, but more of a case of what alternator and blades etc, you use. Furling is a balancing act between force applied to the blades and resistance of the tail boom and angles applied, any one factor can change the other factors. Ita a trial and error to find what works best for your design. Now if you used a common alternator that others have worked with, then we can advise you on what we have learn over trial and error to work best. For example if you used a F&P then there is mass data on the forum about what others have done. If you used a 500w OEM alternator then Phill has done huge development work to suit these. If you want to build a AXFX mill than the Dans and others have well documented their builds. Basically there is no bible to furling, only experience on what others have developed with trial and error to suit a design. Pete. Sometimes it just works |

||||