|

|

Forum Index : Windmills : Will this servo work for a HAWT?

| Author | Message | ||||

| R&DMACHINIST Newbie Joined: 12/07/2012 Location: United StatesPosts: 1 |

Hey y'all I've become interested in building my own HAWT and am wondering if the servo I recently acquired is a good candidate for my project! As my name suggests Im a machinist not an electrician so any info you can tell me on this servos specs would be great! The spec tag reads as follows: Allen Bradley B430P-MJ22AA Series A 460 V RMS L-L3 phase p/n 7043-05-4202 5000 RPM. Freq.0-364 Hz 2.2/3.0 kW/Hp Time Rating Cont. WT 5.5/12 kg/pd Cont Stall torque 6.55/58 Nm/Lb.IN 9.2 Amps O Peak cont. Ke:104 V-Peak L-L/k RPM RS 2.2 Ohms L-L 25c THANKS! |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

The most important part of those specs are the 460 volts RMS at 5,000 rpm and 9.2 amps continuous. Used as a generator the machine will produce an output voltage proportional to how fast it turns. So at 500 rpm you might expect about 46 volts output. Or maybe 23 volts at 250 rpm. That would be the dc output voltage after rectification. You can still get the full 9.2 amps out of it at any speed or voltage, provided the wind turbine can produce enough torque to turn it. That is all a bit simplistic, but it will turn out very close to being what you might expect. In fact you can probably reliably get more than 9.2 amps, because that conservative rating is for a hot motor buried inside a hot machine and operating continuously. Wind turbines are very effectively air cooled <wink> so overheating of the windings becomes less of a limitation. Cheers, Tony. |

||||

| 97fishmt Regular Member Joined: 19/04/2010 Location: United StatesPosts: 77 |

Here is a data sheet on that motor. http://literature.rockwellautomation.com/idc/groups/literatu re/documents/pp/mp-pp001_-en-p.pdf When you can find the Ke on a motor it is easy to figure out what it will do as a 3 phase alternator. Ke: 104... 1000 divided by 104 equals 9.6 rpm per volt. So 9.6 times 13 equals 125 rpm for 12 volt charging or 9.6 times 25 equals 240 rpm for 24 volt charging. 240 rpm is kinda high but 125 rpm might be kinda low. The data sheet says peak amps is 32 amps (name plate amp rating is for one phase). OK I'd probably make a 6' to 8' prop for it and get it to furl to spill the extra power in high winds. The prop size depends on the kind of winds you get and the voltage you choose. Or skip the furling and see if it blows up. The line to line resistance is kinda high 2.2 ohms. It may limit what you can get out of it. I like to get servo motors with the line to line resistance below 1 ohm. Mike |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

Be careful with the 32 amp peak rating. That would only be for momentary locked rotor amps when starting the motor up under full mechanical load. It will overheat very fast if you try to run it continuously like that. Cheers, Tony. |

||||

| 97fishmt Regular Member Joined: 19/04/2010 Location: United StatesPosts: 77 |

The 32 amps is still for one phase, so you still have some headroom. Rectified to DC each phase combines amperage so let it rip. It will get to a point were it will limit itself from lack of input from what's available at the prop. Don't try to put a 10'er on it though. And 8' might be too much if you get strong winds. You still want to be able to stop it with a shorting switch. Just put it up and try to blow it up. I bet you cant. Mike (I take the name plate amps and times it by 3 for a guide to what it can do, if you stay under that then all is well. I've never got one to put out 3 times though, so it's just to get you in the right area with what size prop to put on it.) |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

Just remember that the internal heat generated in the windings will be current in amps squared times the resistance of each winding (2.2 ohms) Nine amps per phase will be 9 x 9 x 2.2 watts of heat in each winding. That is 534 watts total for all three windings. Thirty two amps per phase will be 32 x 32 x 2.2 x 3 = 6.758 Kw. That is an awful lot of heat going into something that size. Cheers, Tony. |

||||

| 97fishmt Regular Member Joined: 19/04/2010 Location: United StatesPosts: 77 |

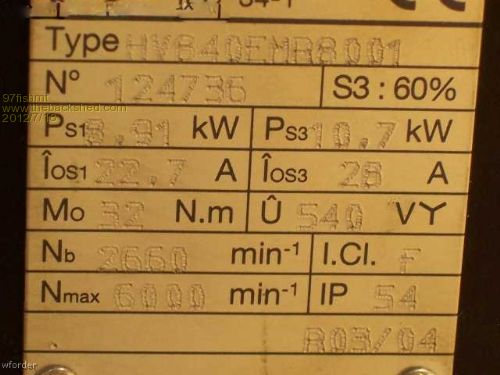

Exactly, You'll never get there. So don't worry about it. From someone that has used servo motors for over 15 years as wind turbines and never had a failure, I'm only trying to support their use in this application and how they perform other than a motor. You wont burn out the windings trying to push power out of one. Find the right motor and the right rotor for your wind is as perfect as you can get. Here is my latest one I'm going to put up on my 65' tower next week.

This one will give the really big one a break. I saw over 1500 watts out of the big one a couple weeks ago but it just needs a bigger rotor to get the power out of it. This one will probably be pushing the limit for a 13' rotor but I'm game. My furling system works like a charm and easily tunable. I'll shoot for 30 volts and 50 amps for 1500 watts to start but I'm sure I can push it to almost 3000 watts. It's line to line resistance is 1 Ohm. I power an off grid home this way and have for many years. Mike |

||||