|

|

Forum Index : Windmills : Embarking on a VAWT project.

| Author | Message | ||||

wallablack Senior Member Joined: 10/08/2011 Location: AustraliaPosts: 164 |

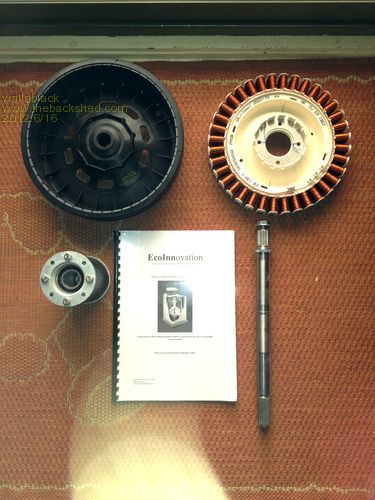

I thought I'd share my build with fellow members and hopefully discuss a few ideas along the way. This is my 2nd F&P project, my first being a HAWT, rewired 6x2C, mounted on Randy's Weldment. I now want to build a VAWT from scratch. I picked up an untouched DC 36 Pole stator, SD type 4 Rotor (Black One), shaft and bearing from evilbay for $70. It was originally purchased from ecoinnovations in NZ for about $200. This will be the powerhouse for the project. I wanted Lenz2 wings. I wanted to recycle as much as I could from previous projects, I wanted it mounted on a 100 x 100 RHS pole (cos I have 6 of these at home). Had to be in a spot lower to the ground (3m) as I plan on testing different ideas so easy access to it would be good. It had to be good for my areas wind, average about 5m/s but has to cope with 14-16m/s which we get often too. As ar as wiring the stator goes - at this stage I might leave it stock to see how it perform, probably change my mind on that before its finished.

This was my evilbay purchase. Good steel to recycle.It was an old brew stand I built for brewing beer which I no longer do. I want to utilize two F&P shafts the older style srews into the new style, as long as the shaft spins the right way I shouldn't have a problem, but will probably put a collar at the join. This is a drawing I did for the mounting. The angled plate was laying around here but after looking at it all cut up on the bench I have decided it would be too weak as it would be bearing all of the forces. Will go for this idea for the bearing mount. The bottom of the frame will have a 140mm x 140mm square flange to bolt directly to the end of my 100 x 100 RHS. This is the 100 x 100 I will use for the mounting pole. They are 3m long each. They came with the house. The squashed end will be under concrete, and 2 will be welded together length ways for height. Any comments more than welcome. Foolproof systems do not take into account the ingenuity of fools. |

||||

| windtinker Newbie Joined: 16/01/2012 Location: New ZealandPosts: 38 |

Hi wallablack Have you thought about making the vawt horizontal? Are you going to use gearing? |

||||

wallablack Senior Member Joined: 10/08/2011 Location: AustraliaPosts: 164 |

I have thought about that windtinker but then I lose a mill. Gearing....I have thought about it and a reason why I will make the whole frame out of the same size materials, so it can be added to if I need to add extras ie gearing. Foolproof systems do not take into account the ingenuity of fools. |

||||

mac46 Guru Joined: 07/02/2008 Location: United StatesPosts: 412 |

Hello Wallablack, The vawt turbines are "not" for everybody...But haveing said that, It will take considerable anchoring to keep the thing planted firmly on mother earth. I might suggest a cross or "x" welded at ground level with anchors at the ends in cement. You may even need to gusset the x braces to the vertical pole. You probably won't spin up the rpms to reach cut in with out some sort of gearing. There has been success with my 'vawt', however I believe it can be made to perform much better. There is lots of reading here on the forum about vawts, and most are willing to help you with suggestions and info. Mac46 I'm just a farmer |

||||

wallablack Senior Member Joined: 10/08/2011 Location: AustraliaPosts: 164 |

Two ways I have considered for foundations. 1. 1 Cubic Metre of 35N Concrete with 4 M20 Grade 8.8 Threaded Rods. Rods will protrude from the conrete about 50-100mm. The base of the 100x100 2-3m tower will have a flange to bolt directly to these rods. 2. Same block as above except the squashed end will be buried into the block. Either way block will not be formed in the ground (shutter & backfill). It will simply be poured directly in the rough dig hole to form a better foundation. Rebar will be used in correct manor as well. Foolproof systems do not take into account the ingenuity of fools. |

||||

| Tinker Guru Joined: 07/11/2007 Location: AustraliaPosts: 1904 |

Regarding using the LenzII wings, good luck with them. You did not say what voltage you are using at your battery bank but I hope its 12V. I tried to get cutin with my LenzII wings at 24V, using a F&P(7 phase) but it never reached cutin for any worthwhile charging time. Tried then with a PM motor from a Shibaru which has a 6.4:1 planetary gear attached, still no useful battery charging, and that's in the wind speed range you quote... My conclusion is that its rather difficult to get the LenzII wings to spin fast enough for cutin of these washing machine PM motors. Even Ed Lenz uses a home made neo magnet type axial flux generator and I do not know how he got his mill spin as fast as it does in his video clip. Klaus |

||||

wallablack Senior Member Joined: 10/08/2011 Location: AustraliaPosts: 164 |

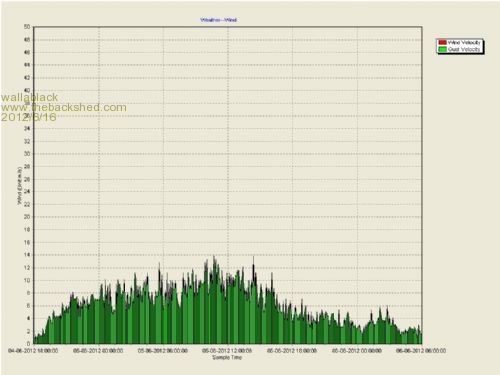

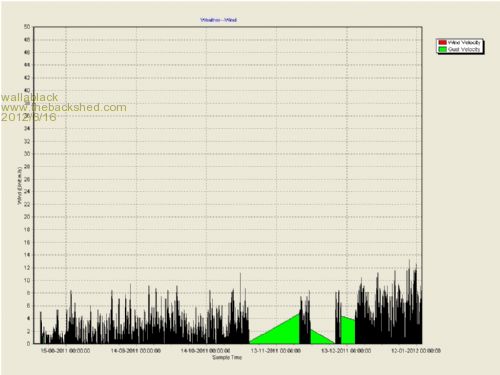

The more I am looking into it the more I like the idea of GE222 or NACA20 profile blades. I am not going to gear it but instead I want to try different wiring on my stator. Why? Cos if it no good I havent spent a million hours building it. I still have 4 kids which need a bit of time too lol. The decogged stator is awesome, it takes nothing to spin but that does not mean it will make good current. The reason for this project is to try different things and learn a bit along the way. My mills and panels are all grid tied but will be changing this to a 24V install in the near future. A couple of weather station files...wind speed in m/s on the vertical axis.

Foolproof systems do not take into account the ingenuity of fools. |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

One problem I had with the Lenz2 on a F&P was the noise. The cogging of the F&P would resonate into the big wings and made a noise like a motor bike passing the house. The newer stators have rounded poles and less cogging, so you should be OK. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

wallablack Senior Member Joined: 10/08/2011 Location: AustraliaPosts: 164 |

Ahhh yours would be the blue one? That was a reason for the possible change to GE222 or NACA20 profile blades. Also the profile blades are available off the shelf which would save time in contruction, my time is limited as 3 kiddies and a 4 month old consume a bit of that. My thoughts on these blades were at first parallel to the main shaft and now I am thinking they would benefit from a slight angle on both the x and y axis. Foolproof systems do not take into account the ingenuity of fools. |

||||

mac46 Guru Joined: 07/02/2008 Location: United StatesPosts: 412 |

Wallablack, You may be on to something by a slight angle on x and y, I would not go to extream with it. Depending on how large this vawt is, you may want to consider a 12 volt starter motor to spool it up to speed...this has made a differance with mine, saves trying to hand crank the thing up to speed. There are other ways also, just a suggestion. I am running 3 home made Goes222 wings...there is lots of power to spare after the wind gets over 20 mph, my normal, average winds are 10 to 12 mph. I shut it down and lock it into mechanical stops "before the storm gets here". Mac46 I'm just a farmer |

||||

| BobMann Senior Member Joined: 30/06/2011 Location: United StatesPosts: 134 |

You may wish to look at this post from steve MPPT working with a Smart Drive It is a Mann Smart Drive using some of my early Lenz blades.I have stepped a way from the wind turbines a bit. I do a lot of CNG convertions on VW and Audis here in the states it helps pays the bills. My site CNGVW shows some of my CNG stuff. Bob Mann |

||||

wallablack Senior Member Joined: 10/08/2011 Location: AustraliaPosts: 164 |

Yeah, nah. Canned the VAWT project. Had it semi welded up and clamped it on it's side on my workbench to work on. Looked good there. Now it is a bench mounted learning / testing / torture unit. Foolproof systems do not take into account the ingenuity of fools. |

||||

Downwind Guru Joined: 09/09/2009 Location: AustraliaPosts: 2333 |

[quote]Canned the VAWT project. [/quote] Good to see you finally come to your senses and realized its flogging a dead horse with the VAWT. A lot of work and little return in the end, not even much good to rest your beer on in the workshop. Sometimes it just works |

||||

Madness Guru Joined: 08/10/2011 Location: AustraliaPosts: 2498 |

You could go back to making home brew and make back into what it was. There are only 10 types of people in the world: those who understand binary, and those who don't. |

||||

wallablack Senior Member Joined: 10/08/2011 Location: AustraliaPosts: 164 |

This is what my VAWT project evolved into. Thought I would share... I basically flipped it onto it's side and clamped it my bench. I brought a $10 bicycle speedo of evilbay to use as an RPM counter and mounted the sensor magnet on the mag hub. I was unsure if it would work as the diameter of the mag hub was greatly smaller than that of a bike wheel...then my brain started working and it does not matter, it is only RPM and is measured by how many passes it make...DUH. I wanted to try the same thing with one of my mills at one stage but the wireless ones don't reach that far and I would have to extend the cable on the wired ones with bell wire or similar...just didn't get my round tuit working. It is a good cheap little test bench now. I have a pulley with a 7/8"/22mm bore I plan to mount to the spline and the other end will be driven by a small electric motor. I found a fairly good nik LG motor the other day, 36 pole, 12 Mag Blocks I would like to have a play with. Foolproof systems do not take into account the ingenuity of fools. |

||||