|

|

Forum Index : Windmills : First windmill for the new home.

| Author | Message | ||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

Well I have the land. Still waiting on the house and shed. Wanted to make my mark, start the ball rolling, do something symbolic of things to come. So I put up my first wind turbine at my new home.

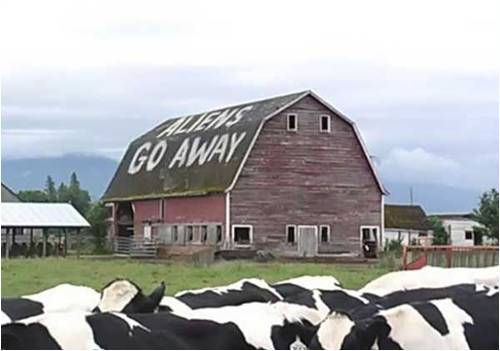

This one has a 30mm diameter all PVC turbine ( cut from some PVC down pipe ), direct drive to a DC generator ( motor from a old printer ). Output is shunt regulated ( 8v zener ) and drives a incandescent lighting plant ( 6v torch bulb ). The tail is aluminium ( from a cut up Coke can ) and tail boom in treated timber ( pot plant stick ), and ballanced ( with a 12mm bolt zip tied to the boom ). I expect a massive 0.5 watts from this rig. It actually felt pretty good to see it spin up after I mounted it to the fence post. I can just imagine the neighbours one windy night. "Whats that glow down near the creek on the place next door?" "Dunno, maybe its a ming ming light. Could be aliens?" "Get me gun!" Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi Glenn You upsetting the natives already. Bob Foolin Around |

||||

| Rastus Guru Joined: 29/10/2010 Location: AustraliaPosts: 301 |

Hi Glenn, From little things big things grow.Cheers Rastus see Rastus graduate advise generously |

||||

fillm Guru Joined: 10/02/2007 Location: AustraliaPosts: 730 |

It's about time , I was starting to wonder when you were going to come out of the maximite section ..  PhillM ...Oz Wind Engineering..Wind Turbine Kits 500W - 5000W ~ F&P Dual Kits ~ GOE222Blades- Voltage Control Parts ------- Tower kits |

||||

| brucedownunder2 Guru Joined: 14/09/2005 Location: AustraliaPosts: 1548 |

Yes, Happy new year everyone .. come out of the maximite --yep, she's a bit heavy in there for me.. Nice to see you "are at the gate" ,,get the brushcutter out and frighten the brownies away .. We have "pete" the python here ,he comes down from our ceiling now and then to catch dinner under the water tap -poor little froggies... Still working on the tracker and Exmork -I'm very slow ,but with acreage to keep nice and this huge house ,then there are many things to do around here. anyone want to visit -you are welcome.. Bruce Bushboy |

||||

| Racingken Newbie Joined: 24/11/2011 Location: United StatesPosts: 28 |

Congrats on the start Glenn. Ken Racingken |

||||

MacGyver Guru Joined: 12/05/2009 Location: United StatesPosts: 1329 |

Glen Glad to see you've finally discovered the joy of building tiny projects. I too am working on a small mill about the same size for my grandson. I'm building an air-core PM alternator that will drive LEDs forming the letter "J" on the tail. My grandson's name is "J"ack. I may do one for his little sister as well with an "L" for Lane. I'll post the build when it happens; soon I hope. Right now I'm about 2/3 done with a small wind-driven diaphragm pump I'm building as a show-'n-tell project for Oscar4u as he has developed an interest in using wind to pump air and eventually lift water using a similar contraption as you posted a while back. The compressed air will push against a container filled with water, where the tank's water outlet is at the bottom and the air pressure forces the water uphill to a cistern. . . . . . Mac Nothing difficult is ever easy! Perhaps better stated in the words of Morgan Freeman, "Where there is no struggle, there is no progress!" Copeville, Texas |

||||

| yahoo2 Guru Joined: 05/04/2011 Location: AustraliaPosts: 1166 |

Glenn, Ya neighbours are right Aliens are bad news! All that probin' late at night when yer tryin ta sleep, it's not natural and a pain in the ....never mind

If they ignore the sign on the shed, then that's it...they are dog tucker

Min-min lights are OK though, apart from flattening all your batteries. FOR SALE pre-loved spacecraft only 15,520,000,000 parsecs on the clock, some small blemishes and stains on the interior, cryogenics sleep chambers need work, no bullet holes, telepathic controls converted for species with single heads. Make a good planet hopper for the missus. all genuine offers considered. NO JOY RIDERS I'm confused, no wait... maybe I'm not... |

||||

| Mickus Newbie Joined: 14/11/2011 Location: AustraliaPosts: 17 |

Gizmo, what did you use for your hub and connection of hub to turbine shaft? Im building on the small scale for my first and am having probs. My first hub disintergrated after 10 mins in brisbane winds, so I am looking for other ideas. I saw a nice home made turbine on holidays in Forster but it too fell apart the next day I went back. Not sure if the small scale leads to more probs. I wanted a system that will fit in a car, for fishing trips (beer drinking trips). |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

Hi Mickus I made the hub from a little block of HDPE ( kitchen chopping board platic ). Its about 10mm thick, 15mm wide and 40mm long, with 3 holes drilled in it. The PVC blade was screwed to the outer 2 holes with self tapping screws, and the center hole is a pres fit over the little motor shaft. I was there yesterday and very happy to see the little windmill spinning like crazy, and its little lightbulb still working. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| Mickus Newbie Joined: 14/11/2011 Location: AustraliaPosts: 17 |

Press fit? Would that lead to slippage? My gen shaft is only 2mm Od, not much to play with Are you able to post a close up of the hub and connection? Im not sure I am imagining it properly and Im heading done the wrong path. |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

We're only talking about milliwatts here, a press fit into HDPE is more than enough. The shaft on my motor was only about 2mm too. Found a photo, its actually an older hub, this one uses tiny metal nuts and bolts to secure the blade to the block instead of self tappers, but its still a press fit onto the motor shaft.

From memory the hole was about 1.5mm or so, a nice press onto the 2mm shaft. If you cant drill a hole thats a neat press fit, you can go bigger and drill another hole in from the side that intersects the shaft hole, and screw in a self tapper to hold the shaft in place. HDPE is very elastic, a brilliant material to work with. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| Mickus Newbie Joined: 14/11/2011 Location: AustraliaPosts: 17 |

I like it, I have been spending my work day not doing work and have a few new ideas. I will definitely try your push fit, I just thought that the constant movement would cause it to expand, oh how wrong was I. Thanks for the pics, helps a lot. |

||||

| rissole Newbie Joined: 10/05/2011 Location: AustraliaPosts: 15 |

hey Glen, congrats on the new place. I would have thought that that tiny turbine (30mm) would be tooo small!!  Rusty |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

Well the little windmill threw a blade. Broke clear off, left with half a turbine. I'm guessing a sudden furl at speed did it, and this is a typical problem with two blade turbines, there is a lot of stress in the turbine when the windmill furls to a new direction. The best way I've heard the problem explained is like this. Take a broom handle, or any long stick, and hold it in the middle. Now hold it vertical, up and down, and turn yourself around on the spot, like a windmill furling. Easy. Next rotate the stick 90 deg so its horizontal, out to each side of you, then try to rotate on the spot again. The stick will resist, and you need to hold it much tighter. Now imagine this stick was spinning around, like a turbine, and you try to rotate on the spot. You will feel strong pulses in the stick, as it rotates through horizontal and vertical position, and in a windmill these can break off blades and shake just about everything above ground level. The problem is non-existent with 3 blade turbines, they have a natural balance. So I decided to make a new 3 blade turbine, just for fun. First I machined up a bit of HDPE. Then used a hole saw to cut 3 slots at 120 degrees. Cut 3 blades from some 40mm PVC pipe. And reshaped to get a nice airfoil. Fitted to the hub, held in place with some metal screws. Finished turbine. Coat of paint to help block UV. I'll put it back together tomorrow when I'm out at the block. Cant wait till I get to play with some bigger windmills

Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| Mickus Newbie Joined: 14/11/2011 Location: AustraliaPosts: 17 |

Nice pics. I like the idea of notching an extra thick hub to allow the blades to sit in it. Regarding the two blade set up breaking. I was told that PVC, even UPVC will eventually become brittle in the sun. I have been trying to make blades but really have been struggling as I only have an angle grinder to work with. If possible, keep those close up pics coming, they help a lot. |

||||