MacGyver

Guru

Joined: 12/05/2009

Location: United StatesPosts: 1329 |

| Posted: 10:23pm 23 Nov 2011 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Why do I feel like Thomas Edison so much of the time? Perhaps it's that we share something in common. When asked if he considered himself a failure, he said, "Why no. I've merely invented hundreds of ways NOT to build a light bulb." Fortunately, his continuing efforts paid off.

I am in much the same situation, whereas I have built several "paperweights" for lack of a more descriptive term, still, I plod on. This build is yet another in a long line of ways NOT to build a genny, but with one exception. This one actually works! Not well, mind you, but with just a little tinkering, it's a keeper.

In that light, here's Mac's version of the Quick & Dirty using mostly off-the-shelf parts:

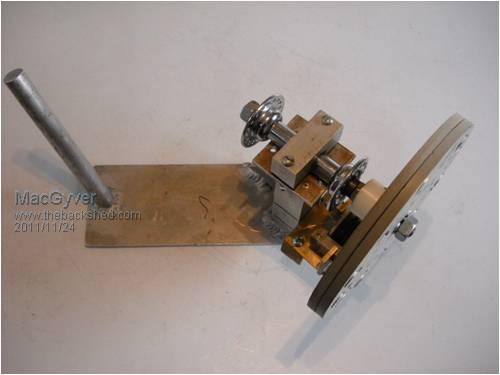

This is a top view of the Quick & Dirty. The working platform is from

another build and is welded aluminum. All the rest of the parts are

OFF THE SHELF and that was the momentum behind building this. I

was after something anyone could build with only basic hand tools.

In case anyone is wondering what all the empty holes are for in this

next picture, they were to hold the soft iron bars shown in this shot.

Originally, I attempted to build an axial-flux machine by reconstructing

each magnet pair into its own little "U" shaped magnet, with a flux-

return pathway through the iron. The idea was to then spin the mags

with a stationary coil between the two and create an alternator. It's

just too small; I tried it and it worked, but I got only a very tiny bit of

electricity for all the effort, so I trashed the idea. Now you know.

Pictured here is a front bicycle hub trapped in a slot and mounted atop

my platform using screws and nuts. The wheel is made of two pieces

of HDPE plastic. Holes for 1/2" neodymium magnets were drilled with

a "forstner" bit. There are two magnets in each hole, doubling their

strength. The pick-up coil is merely an old transformer with its coil

rewired using heavier-gauge wire than came with it. This particular

transformer was actually out of a fish-tank air pump, but any regular

step-up or-down transformer could be used by hack sawing off one or

more parts to form a "U" shape on which a coil or coils are wound.

Here's another view of the same thing. The plastic circles can be cut

using a hand saw and mounted to the hub shaft with flat washers. I

chose to use a bushing and set screw on this one because I had it just

sitting around. The windmill blade would mount outboard of the face

of these two wheels using washers and nuts.

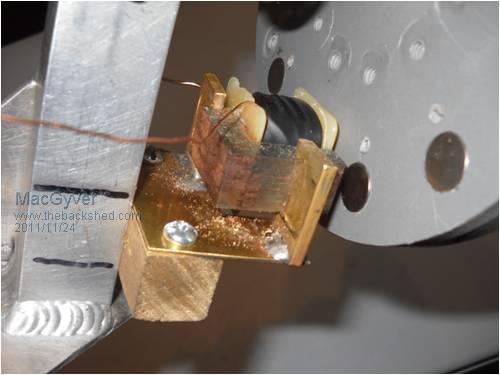

Here we see the little pick-up coil. It works just like a magneto in a

gas lawn mower. Each time a N-S or S-N pair of magnets passes the

ends of the "U" shaped soft metal piece, magnetic flux flows through

completing the magnetic circuit. In so doing, an electric current is

induced into the windings about one or more legs of the "U". Here I

have used only one coil and #14 enameled copper wire. I made the

coil holder from brass and soldered the brass to itself using high-

temp extremely strong solder.

This shows the "air gap" separating the pick up from the magnet array.

It appears to be rather wide for a reason. This is so small, any closer

acts effectively as a parking brake! It generates a current of about 0.1

amps at 10 volts with the shaft spinning about 300 rpm. I know that's

not much, but more pick up stations could be added to a plate mounted

to the bicycle hub's body where the spokes would go, but I've lost interest

in continuing on. It works (barely) and that's enough for me.

This is a bottom view of the pick-up and air gap. The black stuff is

electrical tape around the coil windings. I used the original coil former

from the pump to wind my new coil. There are 12 magnet pair (24 mags)

and since the pick-up sees alternating N-S-N faces, six pick-up stations

could be used to increase the curent or voltage or both. Does it cog?

Does Pinochio have a wooden . . . well, you know.

Since this is the end of my presentation, I thought it only fitting to title

this shot The End. This is a view from the tail post down through the

entire contraption (less blades, tail & tower of course).

Like I said before, that little carrot that dangles out in front making the donkey take another step has fallen off the stick. I've lost interest in building wind turbines that make electricity.

Is this the end of Mac? Certainly not. I'm merely switching gears at this point. When I first came to this 4m, I built windmills that pumped air. I used the air in my greenhouse growing all manner of plants (yes, even THAT one). I got rid of the greenhouse along with the wife and at the proding of one John Tulloch, switched my efforts over to building mills that made electricity directly. Oz & I are still friends, mind you.

Let's just say I learned a lot. The trouble is, I build stuff too small. Heck, that's an understatement; try TOO SMALL with ten-foot-tall letters. Be that as it may, I still like building little stuff, so that won't change. What will change is what I build and from here on out or until something better comes down the pike, I'm going to concentrate on building windmills that pump air, just like the good ol' days.

Instead of using the air in a hydroponic greenhouse to keep all the plant roots oxygenated, I'll go back to building small air-driven engines. If I want to manufacture electricity, I'll merely couple an air engine to an alternator and away we go. The difference now will be my ability to 'effectively' spin my windmill at several thousand rpm via compressed air passing through a small air-driven engine. See where this is going?

I'm not quitting; just moving on. As soon as a certain check valve stops kicking my rear end (meaning I haven't figured out how I want to build it yet) I'll toss up a post showing an air-pumping mill likely built on the same stand shown above! When you live in a shoe box as I do, storing projects is a no-no. Canabilism cuts in at the end of most builds and I reuse parts as do we all in one way or another. The only stuff that will remain for any length of time will be things I build as gifts for my grandson and others, so keep an eye on the forum here or you'll miss out!

. . . . . Mac Edited by MacGyver 2011-11-25

Nothing difficult is ever easy!

Perhaps better stated in the words of Morgan Freeman,

"Where there is no struggle, there is no progress!"

Copeville, Texas |

MacGyver

Guru

Joined: 12/05/2009

Location: United StatesPosts: 1329 |

| Posted: 06:43pm 24 Nov 2011 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Tink

Silly me. What was I thinking? That makes perfect sense. I'll give it a go just as soon as I find that darned carrot; it's got to be around here someplace.

Okay, I'll try that and get back here with the results. Today is "Thanksgiving" in my country. It's a holiday reserved for gluttany; like anyone would need an excuse to overeat! That being said, this'll have to wait a day or two, but I'll give it a go.

As for "Thanksgiving" I'd have to throw in with Joe in the movie Joe vs. The Volcano, starring Tom Hanks. There's a scene where he's sitting atop his luggage floating in an endless sea. It's night and the canopy above is strewn with stars. Anyway, Joe looks up and says, "God in Heaven, I do not know your name, but I'd like to thank you for a great life".

I second that, Joe.

EDIT / Update: Tink, I manufactured a backing plate and spun it up again and you were correct. The the current output nearly doubled. The voltage stayed the same, but then I used the same number of windings, so that much makes sense..

So, ifn anyone decides they want to build one of these simple little rigs, take Tinker's advice and build a backing plate of soft iron such that once it is in place, a paper clip will not stick to it. That means, essentially, that it is sufficiently returning the magnetic flux pathway and you are not losing flux, so it makes things work more efficiently. Also, I would suggest making six pick-up stations and that way you could make a three-phase output, which would smooth things out a bit as it runs.

Thanks, Klaus.

. . . . . MacEdited by MacGyver 2011-11-27

Nothing difficult is ever easy!

Perhaps better stated in the words of Morgan Freeman,

"Where there is no struggle, there is no progress!"

Copeville, Texas |