|

|

Forum Index : Windmills : Wanted: blade set

| Author | Message | ||||

| RossW Guru Joined: 25/02/2006 Location: AustraliaPosts: 495 |

I know there was some discussion about pre-fabricated blades here a while ago... did anything ever come of it? I have a commercial (well, nearly. Chinese job) 1KW turbine but got a $&#%*(*%# noise complaint against me yesterday. Council are checking, but I want to know my options. These blades are 3m dia, fibreglass. No twist, no taper, but they do have a little taper over the last bit of the blade only. So, Ideally, I want to find someone who has or will make at modest cost, a set of full twist, low-noise blades I can bolt to my existing hub. All I know is its a 3m dia, nominally 360 RPM. Existing Hub I'm not able/willing/interested in carving wood myself. I'm not up to makeing one, let alone 3 identical blades! Ideas, anyone? |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

Yes those straight blades with no twist will make a lot of noise. Just my opinion, but noisy blades on these little home wind turbines could/are doing a LOT of damage to the renewable energy / home windmill builder industry. One of the biggest missconceptions about wind power is the windmills make lots of noise, however in fact they are very quiet. A properly designed set of blades should make very little noise. Those cheap imported blades are not well designed, and built to a cost. Personally, I will not ever fly a set of noisy blades for more that a test run. I did have a set of PVC blades on my windmill, but they made a loud whirling noise once they got up to speed, and I took them off that afternoon. OK, back to making a good set. I do have a plan, but need to get started on it. The plan is to CAD up and use my cnc router to make some foam blades, then pass these to Trev so he can make up a fibreglass mould and then sell the blades. These blades will have the correct profile and twist, and therefore run quiet. But cant give any dates yet. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

Also, Trev does make flat fibreglass blades to order. Send him a email and see how much he charges. They have a flat profile, but do have the twist and I believe run with little noise. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| RossW Guru Joined: 25/02/2006 Location: AustraliaPosts: 495 |

This was a "test" mill. But as my first, and with zero prior hands-on experience, had/have no idea how much (or little) noise to expect. They are selling heaps of them, there must be a market for "real" props then :) Glenn, would a bottle of something help "inspire" you? :) |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

Hi Ross Would a bottle of something inspire me? Afraid not, dont really drink anymore, I have a dozen bottles of scotch over 2 years old now for other little jobs. And been off the smokes for 2 weeks now too so the old cigs wont work either. I'll talk to Trev in the next day or two, and I'll have a chat about these blades. What are the blade tips on your blades shaped like, you could try rounding them off. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| RossW Guru Joined: 25/02/2006 Location: AustraliaPosts: 495 |

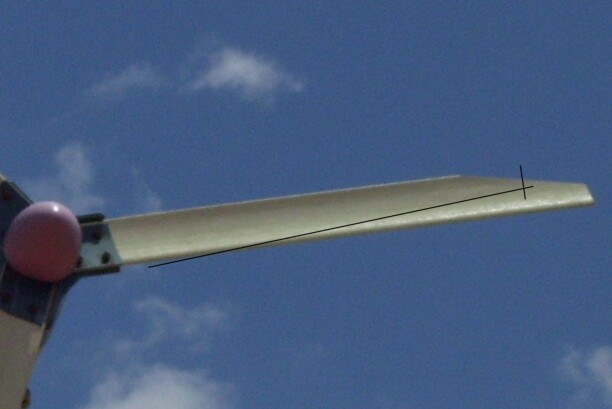

LoL. No vices? Thats no good, we'll have to work on you, Glenn! Fantastic! Closeup of one blade. Sorry its so noisy, the damn thing was spinning, so I had to set the shutter as fast as I could to stop the blurr, and in order to see it side-on, I had to be at a pretty fair zoom, so its sadly lacking in light now :( And here's the whole thing: (same apology about image quality). (The black tape on one blade tip is simply so I can identify "a" blade - to monitor its stopping position to check for static balance over time etc) |

||||

| Pt w/field Matt Senior Member Joined: 24/02/2006 Location: AustraliaPosts: 105 |

hi Ross check out the innovation site he does a few things to the blades like reshaping the leading and trailing edges for less noise on the chinese blades he sells matt down south |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

Dare I suggest this...

Sort of how I did some PVC blades on some smaller windmills. Gives the same effect as twist. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| RossW Guru Joined: 25/02/2006 Location: AustraliaPosts: 495 |

I've tried to find their rotten website, and keep getting health services etc. Can't see it on this site, although I'm sure I've seen it before somewhere. Can you point me to it perhaps? (Hint: googling for "innovation" and anything to do with turbine, blades, paykel etc, turns up nothing thats obviously them!) |

||||

| RossW Guru Joined: 25/02/2006 Location: AustraliaPosts: 495 |

Ummm.... you're saying angle the leading edge? Yikes, these things are 3/4" thick, possibly more just back from the leading edge, and a metre and a half long! I doubt I could cut them straight, let alone put a decent and uniform radius along their length - and then goodness knows how far out of balance they'd be! I'm pretty confident I'd bugger them up and have nothing. I might be prepared to try it if I had another set to fall back on, but at the moment I think thats out of my league, Glenn. You suggested "rounding off" the tip? Leading edge? Trailing edge? Both? *confused* |

||||

| Highlander Senior Member Joined: 03/10/2006 Location: AustraliaPosts: 266 |

G'day Ross, if your looking for eco inn click this http://www.ecoinnovation.co.nz/ As for the noise, a bloke from westwind told me if you want to make blades quiet place tips on the end like on a 747 wing, apparently they do this on the monster turbines they install. His opinion was the theory should work with small blades too, but he never tried it. It shouldn't be too hard to fabricate something that would fit the end. He did say to make the leading edge very sharp. But with no twist there will always be issues that cannot be overcome. As I said It's not my idea, I'm just passing it on. So if anyone wants to poo poo it email westwind. Central Victorian highlands |

||||

Trev Guru Joined: 15/07/2006 Location: AustraliaPosts: 640 |

Hi Ross, Yes, Glenn rang me this afternoon, And he has a few ideas of material etc to try the CNC machine on. Still no dates though. If you had a look at the Windmill Kits and Parts on this site under Foundry & Fibreglass, you can find in there some pics of the 2.9m diameter fibreglass composite blades. (On the White Pointer - full F/g covered mill, and on the bench, just hold your mouse curser over the pic and the name of what it is comes up. Prices are there also. These blades are very quite. If you wanted to try a set of these, we would need to modify your hub, or make adaptors to suit you hub, or make my cast hub to fit your mill. Any thing is possible. But if you want (& able to) wait, Glenn will do something sometime. I also had ideas to do the aerofoil shape but no time just now. I think Glenn has more of the real maths for the aerofoil shape. Trev @ drivebynature.com |

||||