|

|

Forum Index : Windmills : Restoring the Southern Cross

| Author | Message | ||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

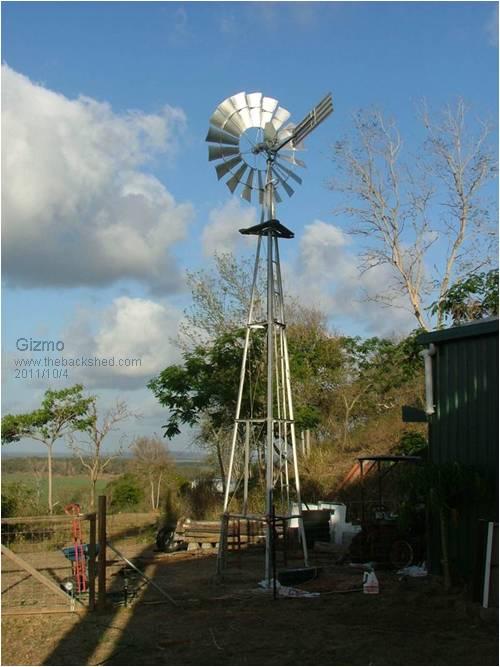

I have an old Z series Southern Cross windmill, just a baby 6 footer on a 25 foot tower. Its about 60 to 80 years old by the model I think. Looks like I will need to put it back into service in a few weeks, pumping water from a bore, so I thought I would give it a bit of a check over. This is it when I had it up in the air in Mackay.

Its now in pieces, transported to my new home town Toowoomba. First I checked the main shaft for play, and it had lots, about 1mm in the bearings. So after spending a few hours knocking/drilling out pins and using my big hammer a lot, I managed to get the shaft out. It was about 22mm ( dont ask me for the imperial size ), very worn out in places, and rusty in others, so I bought a length of 24mm mild steel rod to replace it with. The bearings in this windmill are white metal, poured in place, and not easily replaced, so I figured it would be easier to ream them out to suit a larger shaft. First I used a water blaster to remove decades of sludge and grime from the casing. Reaming the front bearing was easy enough. I then shaped the new 24mm shafts end into a basic cutting tool and reamed out the back bearings. The white metal is like lead, easy to cut. Next I machined the two small sprockets and wheel hub out to suit the new shaft. And machined a keyway into the new shaft and drilled the sprocket pin holes. I also replaced the steel pin on th ecrank that does all the heavy lifting, it was a bit worn!

All back together and oiled up, spins nicely. Next I fixed the fan ( turbine ). The blades were bent and out of shape, so I gave each one a basic panel beating. The finished fan, just before I painted it. I need a bigger workshop! Next I'll put the tower back together and get it all ready to take out to the land. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi Glenn A really nice project practical and reliable it will do another 60 years with a bit of TLC. All the best Bob Foolin Around |

||||

| norcold Guru Joined: 06/02/2011 Location: AustraliaPosts: 670 |

Glenn, Reconditioned one for our block. The brass pump cylinder had gone brittle so made one up using PVC pipe, were not really sure it would last but has been going for almost 2 years now. Because I wanted it to pump uphill (25m head), used 50mm diameter original was 70mm, used a standard poly non-return valve coupled to piston I made of a neophrene type material. Soaked a bit of leather in Lanox, cut and shaped as a bucket(Although the neophrene piston may have sealed well enough) Requires a bit of wind velocity to get going with this head, but performs day in day out no drama. Same mill as yours Z series originally came from Ingham on the coast thus had a lot of corrosin to combat. They were certainly made tough and bloody heavy to gin pole up. We come from the land downunder. Vic |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

Yeah my pump is all brass too, its a bit worn in the middle, and tight towards the ends, so I have to be carefull where I position the piston. PVC, thats a good idea, be a lot lighter too. I dont think I will have a lot of head, maybe 10 to 15 meters from the pump. They dont recommend it, but we used a gin pole to raise the whole assembled windmill at my place in Mackay. Its very heavy, I was using the car as a anchor and at one point it was dragging the car across the yard, wheels slipping on the grass. Once up it's just a matter of climbing up the tower to fill it with oil. I used engine oil, probably a bit thing, will use gear oil next time. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| Don B Senior Member Joined: 27/09/2008 Location: AustraliaPosts: 190 |

Hi Glenn, Being in Toowoomba, you are in Southern Cross country. I don't know whether the factory still exists (it was near the corner of Ruthven and Bridge Sts, if I remember correctly). If it does, you could possibly pop into head office for anything that you can't manufacture (although, with your set up, it looks as though you might be better placed to help them out). Regards Don B |

||||

| Air Bender Senior Member Joined: 25/01/2011 Location: AustraliaPosts: 206 |

Hi Glenn That is good to see, an old southern cross being restored instead of falling to peices like I have seen so many do over the years. When I was young I spent school holidays on the farm with my grandfather and I loved the times we spent doing repairs to the old southern cross. All the Best Dean. |

||||

| dwyer Guru Joined: 19/09/2005 Location: AustraliaPosts: 574 |

Hi Don Being in Toowoomba, you are in Southern Cross country. I don't know whether the factory still exists (it was near the corner of Ruthven and Bridge Sts Southern Cross had moved down from the Toowoomba Range several years ago and is now located at Withcott. The factory at the corner of Ruthven and Bridge Streets are now closed and empty so are the days they had galvonised faculties for windmill frames. I used to work there many years ago and i used to make the windmill blades and other parts.

All the best from Dwyer |

||||

Madness Guru Joined: 08/10/2011 Location: AustraliaPosts: 2498 |

I used to work there too, didn't make that type, the crankcases for them where machined on larger versions of a drill press. I was on a CNC machining centre and made a few crankcases for the big direct drive mills. The machine I was on was the same as Jack Bradham used to build his engines. Didn't realise the Toowoomba foundry is now closed, they even made tanks during WWII there. There are only 10 types of people in the world: those who understand binary, and those who don't. |

||||

| dwyer Guru Joined: 19/09/2005 Location: AustraliaPosts: 574 |

Hi Madness Thank there is more information about Toowoomba Foundry i have it now and did spend half hour writing stories however information was left on this "Post Reply" while l was seaching on other webs site and got back to Backshed' "Post Reply" has disappear and now look like l have to start rewrite all over it again as this was happen before  Glen can you look into it how stop this happen again Glen can you look into it how stop this happen again

anyway Toowoomba Foundry did own "ClayWare" brickwork at Evan Road Kleinton that not near HighField l will post more information about Toowoomba Foundry and Southern Cross windmill hopefully tonight

All the best Dwyer |

||||

| paceman Guru Joined: 07/10/2011 Location: AustraliaPosts: 1329 |

Hi Glenn, That "slightly worn" pin looks like it sees a fair bit of work. I don't suppose you were thinking of using some of your "mild steel rod" to replace it with were you? Something a fair bit harder (and stronger) would be the "go". I'm not up with steel designations these days but years ago we'd probably have specified high tensile R7 or equivalent for an application like that. Greg |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

Hi Greg Yeah I did replace it with mild steel. I'll check, but I was pretty sure the old one was mild too, just old! Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||