|

|

Forum Index : Windmills : PVC vawt

| Author | Message | ||||

| Clogs Newbie Joined: 14/12/2006 Location: AustraliaPosts: 8 |

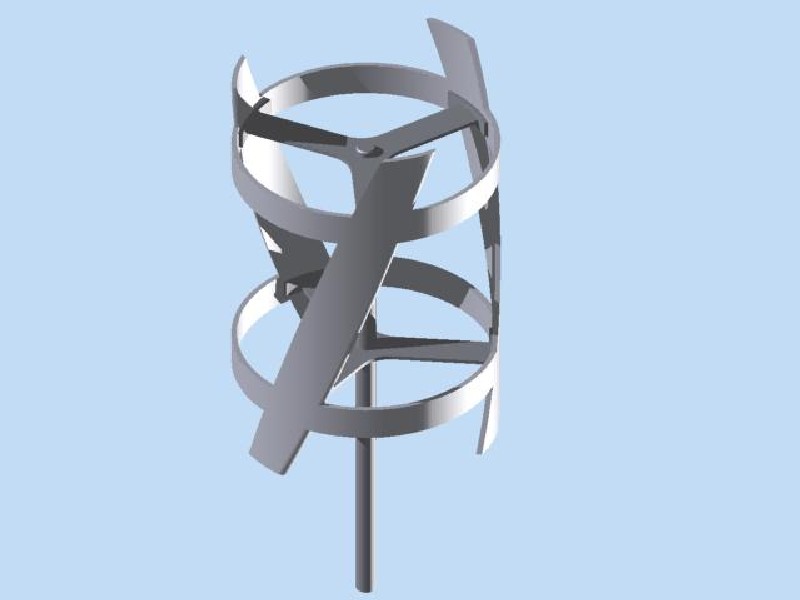

Hi all, Im a long time reader but first time poster. Heres one for the vawt guys. I was looking at a piece of dia 400mm PVC I have for hawt blades and wondered if I could make a vawt out of it. Has anyone tried anything like this? The dimensions as shown are dia 400mm x 600mm high x 10mm thick. Leading & trailing edges would be carved into nice airfoil shape.  |

||||

| Highlander Senior Member Joined: 03/10/2006 Location: AustraliaPosts: 266 |

G'day Clogs, nice graphic, what did you do it on? That looks a bit like a darrius. I've go no idea on vawts just wanted to congratulate you on the drawing.

Glenn or the American boys would be the best ones to give advice on that. Central Victorian highlands |

||||

| brucedownunder2 Guru Joined: 14/09/2005 Location: AustraliaPosts: 1548 |

Yes, magic drawing --can you tell a dope like me how you do that --- must be a hell of a lot of learning how to drive that computer programme? I'd love to do some thing like that but I think I'm tied to the hacksaw and welder in this life. Congratulations Bruce Bushboy |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

Yeah it would work. I have a couple of suggestions. First up, I've marked on your picture where you could leave out the outside hoops, marked with a X. The inside struts will hold the wings in place, and it also means you could make a dozen or more wings from the one length of PVC.

Second, shape the wings to a aerofoil shape like this.

Remember the Darrius wont usually self start, they need a kick to get them going. But once going, they are good performers. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| vawtman Senior Member Joined: 14/09/2006 Location: United StatesPosts: 146 |

|

||||

| vawtman Senior Member Joined: 14/09/2006 Location: United StatesPosts: 146 |

|

||||

| vawtman Senior Member Joined: 14/09/2006 Location: United StatesPosts: 146 |

Yes Gizmo your drawing is right on has to what he should do with the blades and supports. A curved airfoil like that will self start easily.It seems has the wind hits the foil from the side and your off and running.Yours will be a little thin but should still work. I have no problems with starting.No fidgeting back and forth like some has a matter of fact in high winds i block it off just on one side.Doesnt attempt to back up. Attach the blades to the rotor at the very top and bottom. Thats sorta how im doing my rooftop darrius only with many fiberglass blades.Still in the early stages yet though. Go for it. Am i somehow replying to 2 post |

||||

| Clogs Newbie Joined: 14/12/2006 Location: AustraliaPosts: 8 |

The graphic that I posted is a jpeg taken from the model that I drew up in Autodesk Inventor. Inventor lets you render images then save them as jpeg's. It could make a useful little turbine as long as it reliably self starts. I was considering one on the roof of the shed...im in an urban environment so can't go to big & noisy. Vawtman, what generator are you connecting to your rooftop darrius? |

||||

| Clogs Newbie Joined: 14/12/2006 Location: AustraliaPosts: 8 |

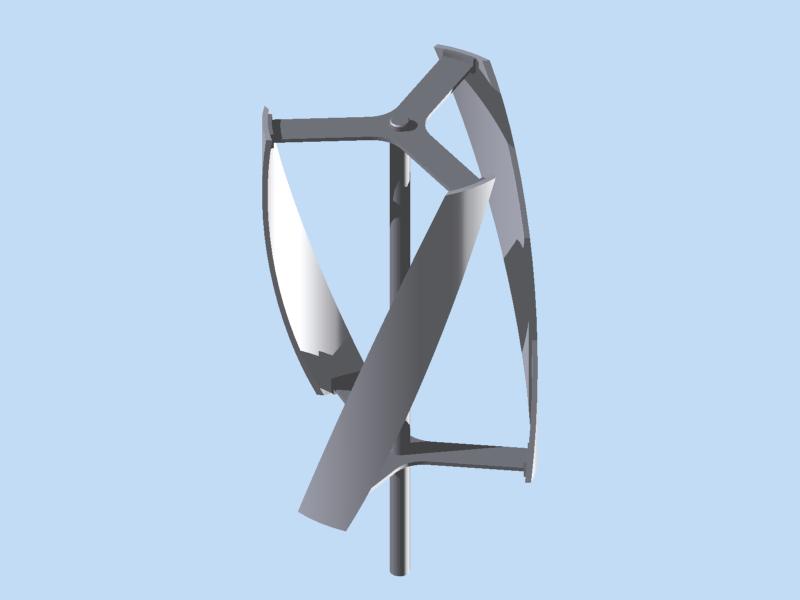

Do you guys mean something like this?  |

||||

| vawtman Senior Member Joined: 14/09/2006 Location: United StatesPosts: 146 |

|

||||

| vawtman Senior Member Joined: 14/09/2006 Location: United StatesPosts: 146 |

Yess Clogs I wish i could draw things like that.If you keep the solidity high like your drawing the turbine wont selfdestruct has the sayings about the darrius. I wasnt planning twisted blades but that might work awesome for ya. Alternator im planning is 12pl 36coil Axial flux design.No cogging(needed for starting) Pics in my files at Otherpower not sure how to bring them here. Nice thing for my climate is the heat generated would make it almost 100% effecient. This turbine will have many thin curved blades.Working on the foam cutter now. Will run silent Carry on |

||||

Bryan1 Guru Joined: 22/02/2006 Location: AustraliaPosts: 1344 |

Hiya Clog, Eh mate I like the design concept and I've been thinking of a way to use the 12" pvc I have here for a vawt. As I have a heap of this pvc I might have to makeup a prototype and test it out. Naturally if this design works out we'll have to name it the Clog Turbine and the credits will go to you for coming up with the idea. Well this weekend looks like I'll be making lots of pvc chips. Cheers Bryan  |

||||

| thefinis Regular Member Joined: 23/08/2006 Location: United StatesPosts: 53 |

The Helix curved blades are excellent but I think that you can get about the same result from straight blades as long as you go with 3 blades. The helix should have the same amount of blade at all points on the circle. The straight 3 blade is close but is not quite as smooth running as a helix. If you can do a good job of cutting the helix do it but if it turns out to be too hard try 3 straight blades same size. You will lose a little blade surface as a diagonal is a little longer. End caps might work for support structure. The circles of pipe in the orignal drawing work well for structure support but take out that area of the turbine blades for power production. They also complicate the cutting and limit the number of blades you can cut from a length of pipe. Bryan have you done the pvc hawt blades? Glenn I am going to post a link to a thread on fieldlines. This is a little calculator to see what size hawt blades can be cut from a pice of pvc pipe. Finis http://www.fieldlines.com/story/2005/4/17/6437/83378 Texas born and bred |

||||