|

|

Forum Index : Windmills : Mann Smart Drive re test

| Author | Message | ||||

| BobMann Senior Member Joined: 30/06/2011 Location: United StatesPosts: 134 |

I have been following Bobs build on his unit and he,s has been very helpfull. I had been running some numbers by bob but it did not make sense. Found that the volt meter on the bourd was shorting out inside. So here we are I think I am on the right track. I set up a stock stator so I could wire it as a star or delta and split the winding up. I am using a 60 unit here in the USA with my modifed trailer drum with Neomagnets set at a 8% angel to help on the cogging. It has been working out very well. I think it is wired right. I tryed this brass bolts they have worked out very nicely. I used a elictric base bourd 1500 Watt with 11 OHMS across the to leads and wired it into a control bourd . This lets me test DC and AC volts unloaded and loaded could not fine my inline AMP meter old one. Here are my numbers todate this is setup in Delta with 10.3 OHM a cross line A B RPM noload DC AC Loaded DC AC 82====== 83.6 62======32 25.4 165======167 123=====47.5 36 I reran it in Star OHM was 33.3 cross line A B RPM noload DC AC Loaded DC AC 82=======14.6 108====24.5 19.5 165======293 214=====30.9 24 I have 3 tranformers coming I am setting one of my Tree Top Wind Mills VAWT up to charge a 24 Volt battery off the grid home on Cape Cod we are mounting it on the back of his old pickup truck on the dunes out back of the home. Bob Mann |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi Bob You will need to get a AC clamp meter to measure the amps out of the machine, and a DC ammeter to measure your loaded DC to get a better idea of the actual output. Looking at the figures it seems to be happier in delta at 165 rpm but will need amp meter to give actual power output. You will also get quite different results when hooked to a 24 volt battery pack as batteries have a very low impedance when charging and will load the unit much more. The split up on the wireing looks good as it gives options for different configurations. I have left mine stock standard, only lifting the star point into the three windings so I have only options of star and delta, and letting the transformers do the voltage manipulation.

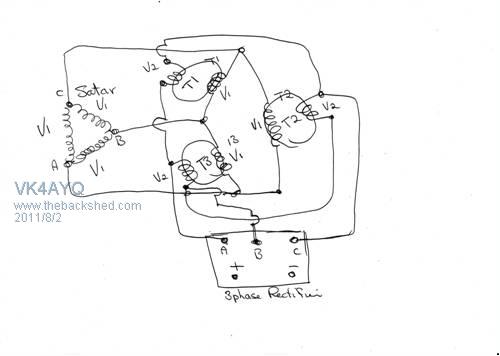

This is the transformer configuration I am using, it is delta to delta but it gives the options of delta star and star delta or star star for different voltage options. For best output I have delta delta with boost module, but for slower cut in I can use star delta, but it loose around 30 % on higher power settings (rpm) it depends where you want the power band to be, of course on the mill it will depend on the power it can extract from the wind, as in the lathe it has 16 HP to work with so drive variables do not show up. These transformers are an overkill for the machine as they are good for 1200 watts each at 50 HZ Just that I had them in the parts box (shed) Keep up the good work All the best Bob Foolin Around |

||||

| BobMann Senior Member Joined: 30/06/2011 Location: United StatesPosts: 134 |

Hello Bob down under I wish I had you shed but I got the VW dream barn. I will grap the meters today.I am planing on working in the lower RPM range with my VAWT when I get it up on the water tower and the grid tie in place. I am going with the Windy Boy for now need it to be UL cert. I plan on puting the wind speed tester up to day but I will see how I feel later must climb 125 ft up. Thank you for all your help all of you. Bob Mann |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

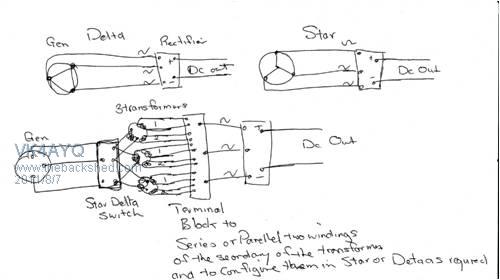

Hi Bob I have been giving some thought to your project and making it as versatile as possible, I have drawn up a mud map of my thoughts to try to help you understand my fractured thinking. The top two sketches are conventional star and delta through a standard three phase rectifier, simple but limited in versatility.

The lower one is a bit complex in that it uses a star delta switch on the generator windings then the three transformers as we discussed, the transformers have two secondary windings of equal voltage say 110 volt primary with two 15 volt windings that can be series ed or paralleled to provide two voltages and then on the same terminal strip the outputs can be connected in star or delta before going to the rectifier. While this may seem a bit complex it allows a number of voltages to be configured for various battery or GTI applications without loosing to much efficiency. All the best Bob Foolin Around |

||||

| BobMann Senior Member Joined: 30/06/2011 Location: United StatesPosts: 134 |

Hello Bob Down Under Thank you for the added layout and up day. I got the tranformers http://search.digikey.com/scripts/DkSearch/dksus.dll?vendor= 0&keywords=vpt48-5200 Bellow is a some pic of you set up will build a nice box today I talked with Tech support the gave me this one i think it may be over kill but I am tested last night it works. I will do more testing today its raining good day for it. I did some volt test This is in Delta open after the rectifier DC no load Here the open volts in delta RPM------- volts DC 82--------- 84 105-------- 105 207-------- 209 210-------- 210 301-------- 300 415-------- 413 600-------- 592 890-------- 860 1750------- over 1000 meter off scale ran very smooth at that speed It follows a nice clean line RPM to Volts If you see a better match at his site for the transformers please let me know witch one to order they are close to me. I am starting to see how this works . I do have a few GTI on hand 20-60 Volt 600Watts and 50-100 Volt 1000 Watts 220 Volts I will try to test to day as well. So what you are saying if I switch the secondary wiring on on one tranformer I can use a devent wiring set on the other to make up the right Volt spreed Cool. I think this is the fix for my USA market as I said you mates are way a head of us on this stuff. I have the data looger up on the water tower at the 120 ft mark been working the last few days I will check on wind speed to day. I should be up with a turbine at that spot this week with luck. Thank you very much all of you. Here are few pic of the water tower Here is were the turbine will be located for the firsr test mid way out. Here is the view what till I get to the top of the tank at 200 ft I would like to build a apartment in the tank it is a monster. It is not used any more dirty. Bob Mann |

||||

| Rastus Guru Joined: 29/10/2010 Location: AustraliaPosts: 301 |

Hi Bob, I've been following your thread with interest.I hope you don't view this as a lame request,I'd appreciate a reference for the star/delta wiring set up you used please.I'm also blown away by the rpm's without balance problems.Hope developement continues to workout for you,Cheers Rastus see Rastus graduate advise generously |

||||

| BobMann Senior Member Joined: 30/06/2011 Location: United StatesPosts: 134 |

Hello I work up some thing later. But for the RPM = Speed I am a race car guy so if you do the math At 890 RPM is 72 MPH with a 27 inch high tire that drum set up can do that for ever. I feel it can do push the 2000 RPM marker with just a little work. Bob Mann |

||||

| BobMann Senior Member Joined: 30/06/2011 Location: United StatesPosts: 134 |

I have full day of testing and I must say Bob Down Under you right on the money with this.I stayed in the Delta group for both stator and transformersbut added you strips. I wired it as a 220 volts primary was the best on that end. For charging the batterys it works like a charm. low speed charging 24 battery bank that is AC AMPs I set up 3 transformers in delta for now this is the fix for the battery off the grid set up. I have tested today working well and I can change wiring around a bunch. I then wired it to drop it for a few grid ties for some testing I found that the power jack worked ok but if I found if you get it working say 200+ Watts then it drop below the the 22 volt low limit it looks like it's working blinking but now watts just hangs there still you cut turbine power this is bad. So I had a Swea set up on hand at the 200 RPM marker it clicked on it runs on a very narrow volt spread. Using a Watt killer in line it would click on and off must of been on its top volt line. but it would read 300watts shut off than click right back on to 500 watts. Than it did it a few more times it hit the 1000Watt marker in to the wall. What do you thing??? Bob Mann |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi Bob Looks like you are having fun with this and getting the sense of it now, it is like having a many gear gearbox in you sports car. I have found that the Power jack Inverters have a problem with synchronization if the voltage isn't held steady within their operating range, also when they do lock on they build up power transfer slowly, around 10 to 20 seconds to full power. I have found that a lot of capacitance on the input helps them work better, on my 24 volt system I use a 250,000 mfd electro. If you push the volts up to high before it loads up the Inverter it will cut out on over voltage, if you put a volt and ammeter on the input circuit of the Inverter you can watch is start up at about 2 amps then slowly draw more current till it reaches its load amps. about 18 to 20 amps input on a 26 volt feed, the amps change according to input voltage and temperature. Also the internal cooling fan isn't big enough and the unit will cut out on overheat, that is a separate issue. As driving the generator by a machine brings it to operation speed to quick for the Inverter to react, because with wind and solar the voltage increase is happening at a lot slower rate. That may be the case with the SWEA unit but I haven't tried one out so only guessing there. Good to see your progress and i hope it all works out well for you. I love your water tower, a friend of mine bought one of these from the council many years ago and converted it into a house, it was fantastic, with a view like you show in the photo. All the best Bob Foolin Around |

||||

| smithy Regular Member Joined: 30/01/2011 Location: AustraliaPosts: 52 |

VK4AYQ Bob That Transformer solution is a very elegent  way of sorting out the desired voltage range required for either charging batteries or going into a GTI. way of sorting out the desired voltage range required for either charging batteries or going into a GTI.

I have a question though. I "short" my wind turbine to slow it down in very windy conditions. How would the above transformer configuration react if I shorted the DC output from the bridge rectifier. Would it still react in a similar way ie, placing extra load on the Alt to such a level that it slows down. I assume the same with a system configured with a dummy load. Smithy "The answer my friend is blowing in the wind, the answer is blowing in the wind" Bob Dylan |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi Smithy You have two issues here. 1. To put on a dummy load, this uses the normal circuit for the DC output and should be designed to absorb the output of the generator. You can have a resistive load and dissipate heat or use a GTI to the mains. 2. Electronic brake, this should be by shorting out the windings of the generator at the AC level and with the minimum resistance possible in circuit, the shorting brake switch should be before ant transformers or other circuitry. the shorting brake should be applied before a high wind event or during one in a lull in the wind to prevent the inertial energy in the blades providing enough current to destroy the switch or cook the wires, it is like slowing a car from 60 klm or holding it stopped, the holding is stopped makes for a lot less energy to be dissipated. If you try this through the DC side of the circuit it will not control the mill and may damage your circuit. I have vaporized the contacts of an 80 amp switch by trying to slow a mill that was going to fast. All the best Bob Foolin Around |

||||

| BobMann Senior Member Joined: 30/06/2011 Location: United StatesPosts: 134 |

Hello this is Bob USA if you look above on the brigeport pic I use a 3 way switch inline from the 3 phase side of the turbine. it can hook up the turbine ,or run free on lock down. bob Mann |

||||