| Author |

Message |

brucedownunder2

Guru

Joined: 14/09/2005

Location: AustraliaPosts: 1548 |

| Posted: 03:53am 07 Jun 2011 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Well,while we are talking about the cost of Neo's ,,I thought I'd like to start a post about cutting Ceramics.. I've some huge Ceramics out of a klystron Satellite uplink Transmitter,, so big I would have to cut them to suit any of my projects.

I have a water cooled diamond saw on a sliding table--the sort you see tilers using to do fine work ..

Anyone know of anybody that has cut ceramics using one of these???.

It uses a 100mm diamond chip blade which are dirt cheap ,, but will the chips from cutting clog up the progress ?.. I'd like to cut ,say, a max length of ,say , 50mm and thickness of 6-8MM ..

What do you think ..

Bruce.

Bushboy |

| |

Barry T Coles

Senior Member

Joined: 30/07/2009

Location: AustraliaPosts: 109 |

| Posted: 08:19am 07 Jun 2011 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Hi Bruce

I have tried to cut ones about the same size as you are talking about with a metal cut off disk with no luck; you will only get about 1-2 mill in before the magnet breaks.

I have some diamond blades & a drop saw setup for my angle grinder i'll give it a try on the weekend & let you know how I go.

Cheers

Barry

I need to learn from the mistakes of others.

I dont have the time to make them all myself. |

| |

Rastus

Guru

Joined: 29/10/2010

Location: AustraliaPosts: 301 |

| Posted: 02:39pm 07 Jun 2011 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Hi Bruce,

I've used demagnetising machines that work on vibration,so I'm wondering if the magnets could be weakened by the cut,even though the diamond wheel may seem smooth in operation.I'm open to suggestions?

see Rastus graduate advise generously |

| |

electrondady1

Senior Member

Joined: 12/02/2009

Location: CanadaPosts: 208 |

| Posted: 02:54pm 02 Jul 2011 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

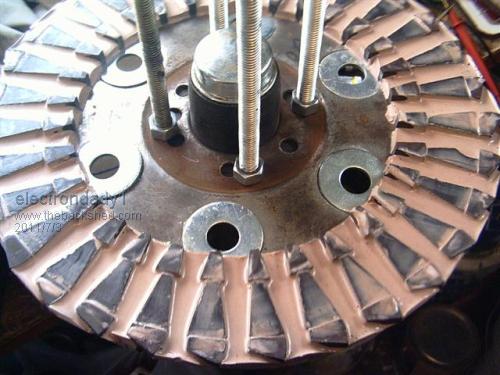

i have cut up a lot of ceramic mags on a tile saw.

starting with round speaker magnets and forming them into wedge shapes for dual rotor axial flux alternators.

it's easy to do and doesn't hurt the magnetic properties.

i would advise a bit of a rain coat and rubber gloves as the sludge that is created is very tough to get out of your skin and clothes.

the mags are very sharp after cutting.

the rubber gloves should be kind of heavy duty.

as well,the sludge behaves very much like iron filings.

and a small amount will stick to the new magnet.

a power washer or a neo mag is handy for removing it.

i used h.d.p.e. (kitchen cutting boards)to form a kind of mitre box jig

it separated the magnets from the table of the saw which was magnetic, and held the magnets securely to facilitate accurate angle cuts.

Edited by electrondady1 2011-07-04 |

| |

Rastus

Guru

Joined: 29/10/2010

Location: AustraliaPosts: 301 |

| Posted: 08:09pm 02 Jul 2011 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Hi electrondady1,

Just out of curiosity,did you happen to take any readings before and after cutting the magnets with a Gauss meter similar to the one on the home page.I'm also curious about the sludge,whether they are like iron filings or they are still infact magnetic?Please accept these questions as friendly inquiries and definately not as criticisms.If the table has a magnetic chuck it may be assisting or even strengthening the magnets being cut.Cheers Rastus

see Rastus graduate advise generously |

| |

brucedownunder2

Guru

Joined: 14/09/2005

Location: AustraliaPosts: 1548 |

| Posted: 08:52pm 02 Jul 2011 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Thanks for the info electrondady,,,

I'm wondering if you could take a few photos of what you did and let me see the muck that you talk of ..

Do you cut with the water dribbling onto the saw ? I have one of these tile saw machine ..

I've some VERY big magnets ,,like half house brick size..

Thanks

Bruce

Bushboy |

| |

electrondady1

Senior Member

Joined: 12/02/2009

Location: CanadaPosts: 208 |

| Posted: 11:47pm 02 Jul 2011 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

ok,

i have no Gauss meter.

but i detected no difference in magnet strength as a result of the cutting process.

the diamond blade draws water up from a reservoir beneath the cutting surface to were it is needed.

the sludge is spun back into the reservoir were it quickly settles out.

when dry the sludge is a very fine powder.

i kept as much of it as as i could for future projects.

you have to let the saw do the work and not force it too much or small chunks will be pulled off, and they do retain there magnetism .

the surface of the saw is not magnetic .

it is stainless steel but it's the kind of stainless that is attracted to magnets.

this thing has also cut up several hundred hard drive mags and they are very temperature sensitive.

|

| |