|

|

Forum Index : Windmills : My new blades

| Page 1 of 3 |

|||||

| Author | Message | ||||

| rinaldoparaipan Newbie Joined: 18/03/2011 Location: RomaniaPosts: 21 |

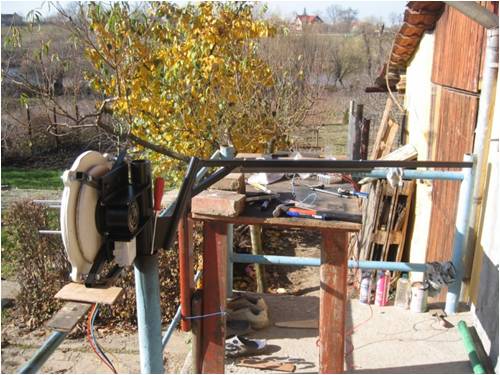

Hello, I already finished my new turbine(the third, after two sets of wood blades);It has an incredible efficiency. The blades are 3,10 m diameter and they are made from epoxy resin and glass fiber coated on a STYRODUR core. The generator is made with 12+12 30x30x20 N42 magnets and the coil has 75 turns 3x0,85 mm cooper wire diameter Estimated power about 1,8 kW http://www.youtube.com/watch?v=q2PL5NikIgI&feature=BF&list=U LvJ1Y8kJ_b_g&index=4 |

||||

fillm Guru Joined: 10/02/2007 Location: AustraliaPosts: 730 |

Very nice work on the blades and mounting with the clamp blocks . It looks like you have done an extreemly profesional job and engineered the blade hub and mounts to with stand the forces exerted on blades . I also went with a similar clamp on my blades that I tested to 6 tonne . What is the airfoil spec ? Why have you been through 2 sets of wood blades and then decided to go to what I would think would have been a lot of thought, design and work to create this blade and hub set? I would think 1.8Kw would be conservitave max power. Well Done  The Rewards for your work and patience will come !!! The Rewards for your work and patience will come !!!PhillM ...Oz Wind Engineering..Wind Turbine Kits 500W - 5000W ~ F&P Dual Kits ~ GOE222Blades- Voltage Control Parts ------- Tower kits |

||||

| rinaldoparaipan Newbie Joined: 18/03/2011 Location: RomaniaPosts: 21 |

The big difference between wooden blades and new blades is the start-up wind speed(about 0,5m/s) and power efficiency The airfoil consists in two NACA type and one S type profile. The major problem was to interpolate the profiles in order to reach maximum efficiency. The maximum estimated power tested at INCAS (The Romanian National Institute for Aerospace Research) was about 2.8-3kW. For the moment I can not give more details, I am thinking to get patent for the type of blades. Sorry for my English, you understand why. |

||||

fillm Guru Joined: 10/02/2007 Location: AustraliaPosts: 730 |

Thats more what I would have expected from a 3.1m set , I have seen 3.2Kw from my 3.15m GOE222 blades on my AX-FX and they have no taper or twist. I am not overly worried about the details , it's just pleasing to see good workman ship . All the best with patent & building them for sale , but mostly these days poeple do not want to pay for quality and strength . PhillM ...Oz Wind Engineering..Wind Turbine Kits 500W - 5000W ~ F&P Dual Kits ~ GOE222Blades- Voltage Control Parts ------- Tower kits |

||||

| rinaldoparaipan Newbie Joined: 18/03/2011 Location: RomaniaPosts: 21 |

You give me a good news with your 3,2kW

I supposed that only in Romania the price is the criteria, not the quality. China kill us. Best regards, Dan |

||||

MacGyver Guru Joined: 12/05/2009 Location: United StatesPosts: 1329 |

rinaldoparaipan Welcome to the 4m. Your blades are other-worldly; very sleek and they look well made. I was curious if these blades fit the profile shown by Alton's Calculator. I entered 3.1 m blades in the calculator and came up with the following data: 11 24.6 488.4 49.8 475 1847 0.94 "1847" is watts (1.8 kw) and "11" is wind speed in meters per second with "24.6" being wind speed in miles per hour. Is this how you came up with your estimated output? I'm wondering if your blade design might actually be more efficient than what is described here as "optimum" on Alton's Calculator or if what Alton's calculates is really as good as it gets. Either way, great job and thanks for sharing. Please let us know your "actual" output results when you fly it. Edit: Here's a Hot Link to your youtube video. . . . . . Mac Nothing difficult is ever easy! Perhaps better stated in the words of Morgan Freeman, "Where there is no struggle, there is no progress!" Copeville, Texas |

||||

| shawn Senior Member Joined: 30/03/2010 Location: New ZealandPosts: 210 |

Welcome to the 4m You have created a winner! those blades with a well matched alt will make a fantastic mill!! You have earned top marks and must be very pleased I would be.       |

||||

| rinaldoparaipan Newbie Joined: 18/03/2011 Location: RomaniaPosts: 21 |

Thank you all for appreciating my work. Unfortunately, my generator is not so powerful to push the blades up to the maximum power limits. The generator was build for my first smaller wooden blades, and “updated” by doubling the magnets. I’m planning to build a new one, in order to” suck” as much power as possible. This is the blades history.

The red one was the result of the cutting test program. |

||||

| JimBo911 Senior Member Joined: 26/03/2009 Location: United StatesPosts: 262 |

Romanian wind mills now thats what I am talking about. Don't stop now we need MORE info and more pictures. Let's see that alternator and all the other goodies we know you have over there??  Jim |

||||

| rinaldoparaipan Newbie Joined: 18/03/2011 Location: RomaniaPosts: 21 |

MY FIRST GENERATOR

PRIMARY TESTS |

||||

Bryan1 Guru Joined: 22/02/2006 Location: AustraliaPosts: 1344 |

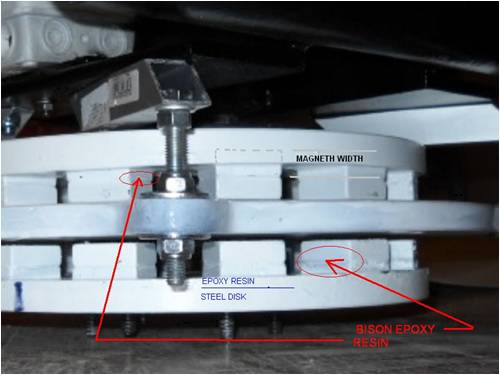

Hi rinaldoparaipan, In that last pic I noticed you have double stacked the magnets, now from what I can see there isn't anything there to stop them flying off in a high wind. My suggestion is put a stainless steel band around the outer diameter of each magnet rotor and epoxy the magnets in. This will help the magnets as moisture will soon get under the paint and the corrosion on the magnets will start before you know it. In the wind game superglue has been re-name stupid glue when people rely only on the stupid glue to hold magnets in place. I have seen many failed pic's of magnets flying off and after the great work you have done I personally would hate to see a pic of the disaster when it happens. Regards Bryan |

||||

| rinaldoparaipan Newbie Joined: 18/03/2011 Location: RomaniaPosts: 21 |

Hy Bryan, Thank you for your suggestions. The new magnets(second row) are glued on the old magnets with Bison Epoxy Metal that has a 160kgf/sqcm bond strength. http://www.bison.net/US/en/view.do?UID=af993e0fc2c7dd2dc07c0 4 http://www.bison.net/upload/af993e0fc2c7dd2dc07c06.pdf The first row of magnets are “buried” about 5mm in epoxy. As seen here http://www.windgenkits.com/video4.htm the magnets are only glued on the disk So, for the second row of magnets I adapted that solution. I hope will be no problems. Regarding the anticorrosion protection, the magnets are nickel-coated. I’ve made some tests with a similar magnet , outside in the rain, and after a month of very bad weather and frost there was no rust spots on it. Anyway, the height of the tower allows supervision and maintenance works. Any recommendations or observations from old experienced persons in windmills construction, is welcome. You have a modified picture with details I hope everybody understand my ideas, I am NOT a native English speaker.

|

||||

| KarlJ Guru Joined: 19/05/2008 Location: AustraliaPosts: 1178 |

hmmm me thinks burnt stator is next but yep nice work on the blades whats the thickness of the plate they are mounted to? AMACK can tell you if it isnt thick enough it will bend and the blades smash into the tower, a shame for such a nice set. Top work so far, the real test as we all know is time, keep the pics coming. KarlJ Luck favours the well prepared |

||||

| Tinker Guru Joined: 07/11/2007 Location: AustraliaPosts: 1904 |

I would agree with Karl, the blade hub plate looks too thin. Perhaps a similar plate could be bolted on top to the studs sticking out of the blade shaft clamps? It would be a shame if the blades hit the mast  Klaus |

||||

| rinaldoparaipan Newbie Joined: 18/03/2011 Location: RomaniaPosts: 21 |

Sorry for the confusion.I did not upload the correct pictures. That is the final shape of the hub plate. It is a spatial structure, so no problems with bending stress. Steel plate thickness is 7mm. |

||||

| KarlJ Guru Joined: 19/05/2008 Location: AustraliaPosts: 1178 |

SWEET

I'd be guessing that blade set will be a sweet thing, I wish I had the time to build some like that  Luck favours the well prepared |

||||

| rinaldoparaipan Newbie Joined: 18/03/2011 Location: RomaniaPosts: 21 |

This is how my turbine is working. Start-up at 0.6m/s wind speed and charging at 2m/s. http://www.youtube.com/watch?v=AJKzdaeX8lg |

||||

| KarlJ Guru Joined: 19/05/2008 Location: AustraliaPosts: 1178 |

Dad loves your scaffolding to work on it  Luck favours the well prepared |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

Hi Dan I edited some of the YoutTube links for you. You can make a link clickable with the  button. button.

Nice wind turbine, and those blades perform very well. Well done. We have another forum member from Romania. Vasi, he lives in Targu-Jiu. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| rinaldoparaipan Newbie Joined: 18/03/2011 Location: RomaniaPosts: 21 |

Hello all, This is my new generator for the blades. 60x30x15 magnets and the coils 88 turns 2mm wire diameter. Tomorrow I'll start to mount it. Let's see what it can do!! |

||||

| Page 1 of 3 |

|||||