| Author |

Message |

energy man

Newbie

Joined: 29/11/2010

Location: AustraliaPosts: 9 |

| Posted: 11:06am 30 Nov 2010 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Hi folks ,

As a beginner in wind gens this is a bit of a headache at the moment .

but im not giving in that easy. Having a 2 acre block in open space

is ideal for what i want to do . 80% of the time it is an eastly

breeze and on sundown it would be about 8 to 12 mabey 15klh wind .

I have pulled apart some smart drives and have some with thicker

wires , so i would use these type .

Thinking of running 2 side by side at 12volt system .

But what configeration do i run them .

I will use the power to run a heap of led lights around in my shed ,

and veranda of my house when it gets built .

a battery bank will be needed but what type sould i use ??? .

I was thinging N70Z gell type ??? .

I wont go on and on but a little bit advice would be greatly apprecative .

I have been wanting to do this for so long , and getting excited .

Cheers to all that can help me Energy Man . Duff.Edited by energy man 2010-12-01

May the wind keep blown folks . |

| |

Downwind

Guru

Joined: 09/09/2009

Location: AustraliaPosts: 2333 |

| Posted: 12:50pm 30 Nov 2010 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Hi Duff,

Not sure what you mean with "side by side"??

Do you mean a dual stator config with 2 stators on the one shaft as is common on the forum here, or do you mean 2 windmills side by side?

Dual stators and leds? Your place will look like tinsle town all year round if you have consistant wind as you quoted.

Have you given any thought to how you will control the mill when the battery is full and you require to dump the power.

What do you intend to use for a tower and to what height.

There is 3 main types of stator with the F&P 60, 80, 100 series, all relate to the wire size 0.6mm, 0.8mm, 1.0mm, can you check what stator you actually have, as it can make a big difference in what config you will need to use to get the best results for the chosen voltage.

What blades are you thinking of using?

The more information you give the better the replys we can give you.

Pete.

Sometimes it just works |

| |

energy man

Newbie

Joined: 29/11/2010

Location: AustraliaPosts: 9 |

| Posted: 09:05pm 30 Nov 2010 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Hi Pete .

Sorry i should of given you more info , i am going to build a dual stator

model on one shalft . I have noticed that the spline on each end are the

same so i think i would try to use it this way .

The Model no of stator is 4256231 with .8mm wire .

To dump my power i was going to use a waterfall pump in a small pond .

My mast height could be about 8 mtrs but would this be higher enough ??

Having a large amount of C channel i was thinking to use this for my

main bottom pole and pivit frame as my pole would clip down inside as

you wind it into place with a winch and lock it into place .

Sorry Pete , I should mention that i have all the pivit constructed off

Plans from the internet and i am using a holden front car hub as the

pivit with the stub axle to be mounted into pole .

Know with very little speep im trying to work the wires through the

outside off the hub and conected to slip rings mounted on the outside

off my pole . ?? Do you loose power through slip rings .

I better mention that im thinking alloy blades , more robust ??

And can i make and electric brake for it in big storms or am i being

silly , and would that be over the top """ .

Please bare with me as im not right up on amps , volts and resistances ,

But the way im going to learn is get my hands dirty and having fun /// .

Thanks again Pete , Cheers from Duff. Edited by energy man 2010-12-02

May the wind keep blown folks . |

| |

Downwind

Guru

Joined: 09/09/2009

Location: AustraliaPosts: 2333 |

| Posted: 04:18am 01 Dec 2010 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

You talk of an electric brake......do you mean shorting the windings out as a brake, as this will not work well with an iron core machine like the F&P.

A dump load needs to be a resistive load that can take whatever power your mill throws at it under any condition.

A pond pump just wont cut it as an diversion load.

Some use light globes but i hate the idea as the first high voltage surge will blow the globes and you then have a runaway mill

Ok you have some 80 series stators, and for what rewire config to use have a look on the forum front page for the various recomendations for your voltage.

It would seam you have the tower sussed, and i would think 8 meters should work well, but you know your winds in your area better than me.

You shouldnt loose power through sliprings and is so than would look for a slipring problem.

Pete.

Sometimes it just works |

| |

energy man

Newbie

Joined: 29/11/2010

Location: AustraliaPosts: 9 |

| Posted: 04:51am 01 Dec 2010 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Hi Pete , If i run the angle type tail wing this might help with the

blades spinning to fast .

What would you seguest would be an idea for dumping off

power loading , do you mean like a house hold fan or something .

Sorry but im still a bit grey in this area , some others would

give up on me but unless i have a go i wont learn a thing ..

I will do a bit more searching on web for ideas .

I think alloy blades my be go . Must see who sells them ,

as i need to keep collecting more bits .

Cheers Pete , You have been a great help and keeping me

interested . Cheers Duff ...

May the wind keep blown folks . |

| |

shawn

Senior Member

Joined: 30/03/2010

Location: New ZealandPosts: 210 |

| Posted: 06:11am 01 Dec 2010 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Hi duff one dump load I recomend is this it is is high tensile fence wire around an old tube light, Bullet proof and cheap!

I had lights but a power spike blew them! |

| |

energy man

Newbie

Joined: 29/11/2010

Location: AustraliaPosts: 9 |

| Posted: 06:53am 01 Dec 2010 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Hi Shawn , What were you running a 12volt system ??

I wanted to use my dumped power some how with out wasting it ??

Or am i barking up the wrong tree .

Any way thats one idea , Thanks for your imput , It all helps

Cheers Duff...

May the wind keep blown folks . |

| |

Downwind

Guru

Joined: 09/09/2009

Location: AustraliaPosts: 2333 |

| Posted: 08:13am 01 Dec 2010 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Woof, Woof, you are barking up the wrong tree.

A dump load is your last line of defense to keep the mill under control and it needs to be a reliable bullet proof system.

As Shawn quoted he had lights for a dump till a good windy day and the globes blew and the voltage went sky high and killed other electronic equipment, He resorted to running the vacuum cleaner for many hours to keep a load on the inverter to draw the batteries down so the mill remained loaded.

The fluro tube wound with wire was a quick and dirty way to get him out of a bind for the need of a quick dump load, it has worked very well for him and he has kept it as it was reliable.

Just wind some wire (steel wire)around a broom handle then slip it onto the fluro tube.

The longer the wire used the higher the resistance so the lower the amps it will draw.

If the mill is not being loaded enough in strong winds just shorten the wire length.

Shawn's system is 24 volt.

You still can use the power instead of wasting it as the dump load is set so if the battery voltage goes too high it will switch to dump and as the battery voltage comes back down it switches back to the battery charging again.

It is just there to protect things from over voltage, as you cannot disconnect the windmill from a source of load (as you can with solar) the power generated needs to go somewhere and if the batteries cannot use it then it must be diverted to another load like the dump or a water heater etc.

I think you are also expecting to generate more power than you actually will make, so i would say just use a dump load to start with and once all is up and running then worry about what other use you might have once the battery is fully charged.

One step at a time, as regardless what you decide to do you will still need a dump load system in place.

Pete.

Sometimes it just works |

| |

energy man

Newbie

Joined: 29/11/2010

Location: AustraliaPosts: 9 |

| Posted: 08:53am 01 Dec 2010 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Cheers Pete , Know im starting to get things in my head and under standing a

few things . All the coggs will line up one day . Ha Ha

Wanting to start wiring up these stators but ive done that much

reading that ill think i will wire up both stators the same way

Or do you think i should stagger them , and will still run with a

12 volt system .

But after reading a bit more I think i should be running a

24 volt system for better performance , As batteries wont be a

problem i should go this way ....

Cheers Duff ...

Edited by energy man 2010-12-02

May the wind keep blown folks . |

| |

Downwind

Guru

Joined: 09/09/2009

Location: AustraliaPosts: 2333 |

| Posted: 12:47pm 01 Dec 2010 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Im not the expert here on the best choice of voltage systems, but since noone else looks to be jumping in here to help out, i will say this.

The higher the voltage system the better the efficency, so 24 volt would be better than 12 volt........but it is not easy to get a good rewire config for 24 volt and might be worth looking to a 48 volt system, as many here have had good results with 48 volt rewires.

With a bit of luck Gizmo or some else better in the know than me might be able to advise you best on what path to take with your stator configs.

Pete.

Sometimes it just works |

| |

shawn

Senior Member

Joined: 30/03/2010

Location: New ZealandPosts: 210 |

| Posted: 07:06pm 01 Dec 2010 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

With all things there is a compromise,48 volt is best but cost the most,12 volt cheapest but the most losses. My mill a f&p dual two 80 stators in half deltor with caps runs sweet!

But pete is right and we all overestimate how much power we will make (at the start)I do not think my mill could make more power over a year with my wind (hard to improve)

so as most here i will be building bigger!

Go for it with the f&p as they are a great mill to learn with and very forgiving when things go wrong,

If you catch this bug as bad as most you will want bigger!!!! |

| |

AMACK

Senior Member

Joined: 31/05/2009

Location: AustraliaPosts: 184 |

| Posted: 10:03pm 01 Dec 2010 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Hi Duff,

You will find allot of nice people on this forum and allot of different views on topics. I have played with the f&p's and had a few crashes too. If you need advise this is the place to be.

I run a 24 volt system with 875 amp/hr batterys and a latronics 24volt 1800 watt invertor and wish it was 48 volt but battery costs are double and the invertors are expensive too in 48. I all so have 1.7 kw grid tie system too and I have seen 1969 watts from it at times when it is cool and sunny.

Going 48 volt gives you allot higher end rang in invertors them 24 and larger watt mills some times only come in 48 120 240 350 volts too. I have found it hard to get a mill over 2000 watts in 24 volt without spending allot of dollers.

Keep at it and it will happen, the only silly questionn is the one you don't ask.

AMACK

*Note to self

1. Make it thick

2.Make it heavy.

3.Make it stronger than it should be.

4. Don't rush the first job as the second job will cost more and take mor |

| |

energy man

Newbie

Joined: 29/11/2010

Location: AustraliaPosts: 9 |

| Posted: 11:57pm 01 Dec 2010 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Thanks Fellas , I do ask alot of questions , But ive been told little steps

makes big progress . . . When your so keen on something

its hard to get out of top gear , needing to slow down a little.

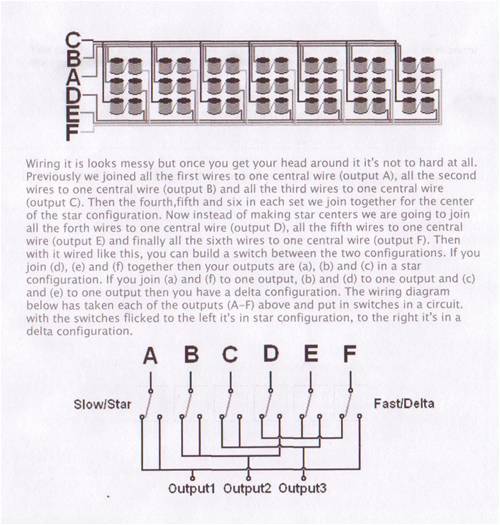

Anyway im not going to go on and on ,This is what i had i mind

Running a 24 volt system with a good bank of batteries .

here is a wiring diagram i was going to use .

Must say a big thanks to BigDog , he"s been a great help .

Anyway Thanks guys for all your imput its been great .

Slow down , little steps . Cheers Duff .Edited by energy man 2010-12-03

May the wind keep blown folks . |

| |

Downwind

Guru

Joined: 09/09/2009

Location: AustraliaPosts: 2333 |

| Posted: 03:37am 02 Dec 2010 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

All very good, but what happens when the switch fails at some stage (as it will)??

What controls this and gives a hysterias or it my cycle a 100 times a second.

Star/delta switching has been discussed many times but there is always the chance of a runaway mill with a switch failure, if you are lucky it might just short the windings and hit the brakes.

Pete.

Sometimes it just works |

| |