|

|

Forum Index : Windmills : Wind turbine project

| Author | Message | ||||

| hodgepodge Newbie Joined: 30/10/2010 Location: Posts: 2 |

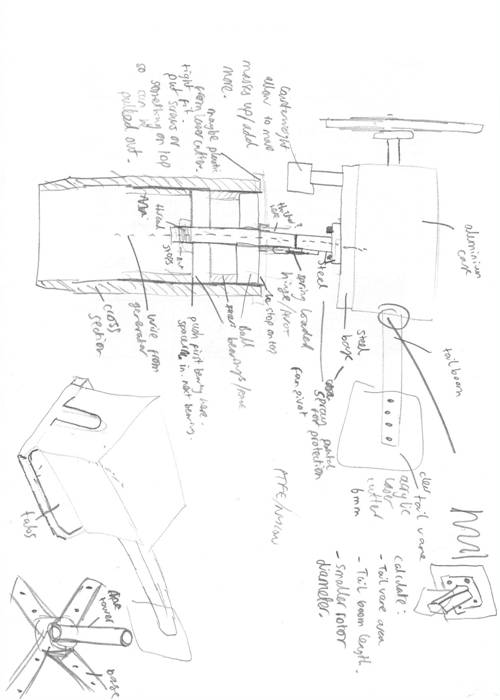

Hello I am designing and making a wind turbine for my last year school project. The image I have attached shows the very rough sketch of my intial final design. The scales are off as the rotor diameter will be 0.8metres to 1.0 metres, but the drawing just serves as a way of helping me understand my design. My problem is the pivot point which allows the top part of the wind turbine to tilt-back in high speed wind conditions. I went for this method of protection so I could simplify the design so to speak, due to limits of money and materials. The problem is that I dont have a great idea of allowing the top part of the wind turbine to tilt back. If you have any advice on this problem, or on any other area in the rough design, could you please help me? Many thanks

|

||||

Downwind Guru Joined: 09/09/2009 Location: AustraliaPosts: 2333 |

hodgepodge, Welcome to the forum. Your tilt back idea has been tried by several (not so much here on this forum) and it is far from the simplest design and has one great problem. That is, as it tilts back it creates a big giro and has some very brutal effects. The most simplest form of control is a tail and yawing the mill. This is a much more user friendly method. If you want information on tilt back systems i think i have seen several on "OtherPower.com " forum. Perhaps you would like to explain you design some in words as the sketch is not over clear of what you intend to do with what components. Pete. Sometimes it just works |

||||

| itsandbits1 Regular Member Joined: 13/08/2010 Location: CanadaPosts: 81 |

I think you picked one of the tougher ones to try. that being said. I had an idea for making one using a hood closer damper or one from the back lid on a hatchback. They have the iinternal pressure and a slow return so it would not slam back and forth. If you expect it is going to get used a lot I would put one each way. Or for hd use an ordinary car shock absorber with a spring |

||||

| electrondady1 Senior Member Joined: 12/02/2009 Location: CanadaPosts: 208 |

i've never built a hawt but was under the impression that for modest size rotors like you intend to build furling out of the wind is unnecessary. |

||||

MacGyver Guru Joined: 12/05/2009 Location: United StatesPosts: 1329 |

hodgepodge This Link explains furling, which after all is said, done and understood, is actually pretty simple and works well. It's likely the one Pete is talking about. I think for you, this method would be the easiest to build and most effective to use. . . . . . Mac Nothing difficult is ever easy! Perhaps better stated in the words of Morgan Freeman, "Where there is no struggle, there is no progress!" Copeville, Texas |

||||

| hodgepodge Newbie Joined: 30/10/2010 Location: Posts: 2 |

Thanks for the replies. I did intend to use furling to protect the wind turbine but honestly could not fully understand how to use it on my design as you can see in the drawing above. I spent hours trying to understand and make up a furling system for the wind turbine in the drawing above, but to no avail. What would I have to do? I kinda get about offsetting the tail and whatnot, but fail to understand what happens when the tail furls and how. |

||||

MacGyver Guru Joined: 12/05/2009 Location: United StatesPosts: 1329 |

[Quote=hodgepodge]What would I have to do? I kinda get about offsetting the tail and whatnot, but fail to understand what happens when the tail furls and how. I don't understand all I know about this, but it's been explained to me by someone who apparently knows what he's talking about that as the turbine "loads" (begins generating electricity), it somehow (magic?) pushes back against the wind more. As this happens, being set against an off-set pole mount, it tends to rotate the yaw platform in the direction the wind is facing the blade. This in turn causes the tail to appear to fold up behind the turbine when watched from in front or from below. In actuality, I think as the force against the blades begins to approach and overcome the force of the weight of the tail (remember, it's sitting, hanging on an angle), it somehow relieves that force. All the while, the tail stays in the flow direction of the wind, cause that's just what tails do and as this happens, the angle of incident wind on the rotational plane of the blades makes it slow down and come back into balance. Re-re-re-re-re-read the link I sent you and it'll all fall into place eventually. Even if I don't fully understand it, the fact that it actually works is enough for me! . . . . . Mac Nothing difficult is ever easy! Perhaps better stated in the words of Morgan Freeman, "Where there is no struggle, there is no progress!" Copeville, Texas |

||||

Downwind Guru Joined: 09/09/2009 Location: AustraliaPosts: 2333 |

You might want to also have a look at the F&P mill Glenn built thats on the front pages of the forum here http://www.thebackshed.com/windmill/fp2a.asp This should give you some idea of narcel design and how it all goes totether with tail and yaw bearings etc. Pete. Sometimes it just works |

||||

| Perry Senior Member Joined: 19/11/2009 Location: Posts: 190 |

Hey Hodgepodge, Tilt back furling turbines may not be common but they are a reality and can be quite functional for a small turbine like you are proposing. With such a small rotor the gyroscopic moments are manageable plus as a school project I don't suspect you are looking for a machine that will power your house for the next 10 years.

I like the 'oddball' turbine and dream up ways to build them....even if I don't Here's an interesting video that may inspire you. http://www.youtube.com/watch?v=5htzHADqxE8&feature=fvw There was another one I am aware of but I need to search out a link for you. Perry |

||||

| Perry Senior Member Joined: 19/11/2009 Location: Posts: 190 |

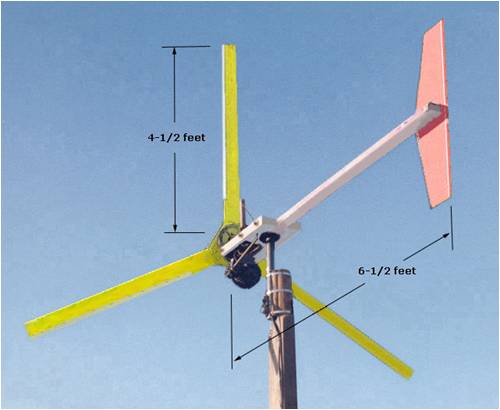

Here's a couple more pics. This isn't my turbine and I can't remember where I found them on the web so someone out there deserves credit but I think they illustrate an easy way to accomplish what you are trying to do. Perry

|

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi Hodgepodge I have tried the tilt back system years ago and found it a bit of a problem in gusting as the continual tilting causes a lot of gyro forces right where you dont need them and puts a lot of strain on the top of the mast. I have now gone the non furlong way to give it a try and I think for small blades it is the best, the blades need to be made for 40 ms + wind and have a higher speed generator configuration. The one I have up at the moment is an old design Chinese turbine and I have tries blades from 6 ft to 10 ft. The smaller blades make it a bit useless in low wind, less than 6ms but are really good over that and with gusts to 40ms no problem. The 10 foot blades worked better at low speeds cutting in above 3.5ms with full output at 12.5 ms, but in 40 ms gusts they where scary, they worked but I didn't consider them safe. I have now settled for a set of 8 ft blades that cut in at 4.5 ms and once again full output at 12.5ms and in gusts of 40 ms they really whistle but are much safer than the big ones. All of this testing was done with the furling locked up. I pulled the alternator down last week for a look and no sign of heating or any damage due to high speed, all I did before I put it up in the first place was fit high quality bearings as the original ones where a bit tatty I think if you can accept the low speed loss non furling is the way to go providing your blades can stand 1500 rpm. All the best Bob Foolin Around |

||||

| wind-pirate Senior Member Joined: 01/02/2007 Location: CanadaPosts: 101 |

Hi Perry They mill you posted is at Dragonflypower. com. He has plan's posted there for sale. This is a very simple design. You can use most any type of generator/Alternator. The nice part is you can shut down your mill when needed. This may not be the best furling system I have seen, (But it works). I built one simular to this. but, with a 4 blade. The blades have lots of power, but turns slower. ratio is 4: to 1.0 with a large treadmill p.m. The brushs don't last long in a treadmill motor. The old windcharger "we had" used the same tip up system. 1940's And a rope to put is out of order when not needed. Ron THE Pirate. stealing wind & solar energy is fun |

||||

MacGyver Guru Joined: 12/05/2009 Location: United StatesPosts: 1329 |

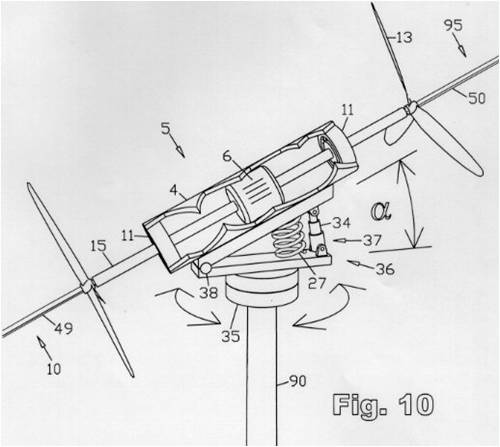

hodgepodge Here's another way to make a tilting system that looks to be pretty easy and straight forward:

I lifted this picture from here: http://www.speakerfactory.net/wind_old.htm In your case, the spring tension could be such that at a pre-determined wind speed, the pressure against the blades could overcome the force of the spring. Also, an "emergency furling system" could be built by merely having a rope dangle from the top of the yaw platform; you could manually yank it down in a storm. I know the picture shows it "running" in what would be a "furled" position for you, but I wanted you to see the spring-loaded platform. Instead of compressing the spring, yours would likely pull against it; same difference. Also, the emergency yank cord would likely pull a pin or you could even take up the tension with it and tie it off on your tower with a small boat-tiedown fitting. Just a thought. . . . . . Mac Nothing difficult is ever easy! Perhaps better stated in the words of Morgan Freeman, "Where there is no struggle, there is no progress!" Copeville, Texas |

||||