|

|

Forum Index : Windmills : My new mill

| Page 1 of 9 |

|||||

| Author | Message | ||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi all I have been very impressed by the new Wind turbine that Fhillm has supplied AMACK, the performance of the unit has exceeded all expectations, so much so that I have purchased one last week, I have taken a few photos of the unit as I unpacked it and hope to document the erecting and modifications to improve the standard unit from a 500 watt rating to a 1000 watt plus unit. I live where there is low wind speed most of the time, so I have been looking for a mill to optimize for low wind speed. This little beauty fits the bill, it is based on a Chinese built alternator that is simple and robust, but as with all things Chinese it will take a bit of work to bring it up to a reliable and reasonable priced machine.

This is the box of goodies as delivered. It has a well constructed tower as well at 6 meters high, it was originally designed as a free standing tower but with the modifications I will be doing to the mill it will need guy wires for added support, I plan to extend it several meters higher as well, but the basics are good and well engineered out of heavy wall pipe with bolt together flange couplings, top marks for the tower.

Note the heavy duty base that the mast tilts on, it is designed to be mounted on a concrete base and has the base bolts included in the kit. The base plate is 17mm thick and is galvanized to prevent corrosion on this critical component.

Note the bag of bolts and fittings as well , very comprehensive, even has pre- drilled lugs for the guy wires, no wires or turnbuckles though, you can't win them all I suppose.

The generator is simplicity itself with the blades mounted around the outside of the unit. The construction is good but will need several little modifications to deliver the power I want to pull out of it, and a few electrical upgrades to carry the extra amps.

The mechanics of the head are well constructed with roller bearing and ball thrust bearings used on the masthead. You will notice that the tail is to short for stability, so that will be lengthened and the vane enlarged for more stability. The blades are the time and result proven extruded aluminum blades, mounted on steel tubes that spigot into the sockets around the alternator.

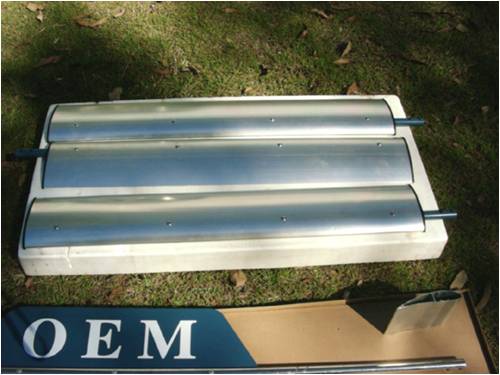

The extruded airfoil section is a high efficiency low speed airfoil with a generous cord for slow speed performance. The blades will be extended to give a larger diameter and hence a larger swept area to optimize the low wind speed performance. This is the main reason for the guy wires on the tower modification.

As you can see the blade extrusion is very robust and allows the diameter to be increased significantly without any structural problems. I will post further progress on the turbine as I go along for the interest of all. All the best Bob Foolin Around |

||||

AMACK Senior Member Joined: 31/05/2009 Location: AustraliaPosts: 184 |

Bob, Good to see you got it and hope it goes well. Even if you don't have the wind I get here you will get some good output I am sure. AMACK *Note to self 1. Make it thick 2.Make it heavy. 3.Make it stronger than it should be. 4. Don't rush the first job as the second job will cost more and take mor |

||||

| Perry Senior Member Joined: 19/11/2009 Location: Posts: 190 |

I like the gen design. Do you have anymore info on it? Does Phil have a website or something that outlines the turbines he is selling? Perry Never mind on the site link. Googled it. No info on the alternator on there though. |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi Perry Not much information on the Alternator from a tech point of view, the design is based on a 1000 watt wheel motor 48 volt in star configuration, I will be using in 24 volt charging so I will reconfigure to delta and set up Gordon's cap modification to get the low rpm working, the original wiring out is a bit light so Phill has given me a bit of 3mm wire to make that more realistic. To fit the 3mm wore I have to drill out the hole in the shaft a bit. Phill hasn't got a site up yet as I think the whole thing is still in the development stage and he has just offered a few units to members at a cost price to get them out to work on and document results. Judging on the results AMACK had got from his it should be a real success, and usable on 24 and 48 volt systems using star and delta configuration. I will pull it all to bits and post photos in the next few days so everybody will have a better idea on the internals. All the best Bob Foolin Around |

||||

| dwyer Guru Joined: 19/09/2005 Location: AustraliaPosts: 574 |

Hi Bob and all members I have brought the Mill from Phill few week ago I have been very impressed by the new Wind turbine  and at the moment it not up yet and doing some interesting modification work on the blades and hubs and going to add length to the pole to 9 metre reason few tree is out of the way and will post some photo soon to Phill first before anyone look it as now l am still play around with F&P windmill however slowly move away from it and later might go buy other Phill mill in near future reason very thing is in the box ready to setup and never go buy any windmill on Ebay again because of many reason l had problem in the past and at the moment it not up yet and doing some interesting modification work on the blades and hubs and going to add length to the pole to 9 metre reason few tree is out of the way and will post some photo soon to Phill first before anyone look it as now l am still play around with F&P windmill however slowly move away from it and later might go buy other Phill mill in near future reason very thing is in the box ready to setup and never go buy any windmill on Ebay again because of many reason l had problem in the past

Dwyer |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi Dwyer Glad to hear you are progressing with yours, I also am extending the tower three meters because I am putting it through the roof of my shed and want a bit more clearance above the roof. Are you taking the blades out to 2.8 meters to increase the swept are a bit?

All the best Bob Foolin Around |

||||

fillm Guru Joined: 10/02/2007 Location: AustraliaPosts: 730 |

Hi Bob, Good to see you have started on getting it up and flying , I will also be interested in seeing what mods Dwyer has and is doing to his . Perry, I posted some pics of this quite a few weeks back and it has pics of the stator ect , I will bring the thread back to the top so it can be seen even thogh it was a bit contaversial. Glenn also has one of these up and flying , the only mod he did was a tail extension and to wire it to delta and correct the blade angle , it did punch through 500w with the 2.4mt Dia blades. I will add though , these will be not a good 48v gen as the cutin will be up around 680Rpm ( 340 with a cap/dblr ). PhillM ...Oz Wind Engineering..Wind Turbine Kits 500W - 5000W ~ F&P Dual Kits ~ GOE222Blades- Voltage Control Parts ------- Tower kits |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

High Phill I would like to give one a go as a 48 volt machine in star for a future project, could you suggest a configuration to make it work. I wouldn't need the high output as in 24 volts, a output of 500 watts would be more than acceptable, and may be a bit less stressful on the wiring as it would be more suitable to the lower amps. At around 9 amps at 55 volts would be real good. Whats your thoughts on this. All the best Bob Foolin Around |

||||

fillm Guru Joined: 10/02/2007 Location: AustraliaPosts: 730 |

Hi Bob , By using the Cap/doubler and in star, cutin should be around the 170rpm for 48V , I havn't tried this with mine but it is worth a go now you mention it . The Rpms will make the blades a little noisy untill loaded . Buy looking at my data on my origional testing on the lathe it will be similar to 24v Delta which works very well . PhillM ...Oz Wind Engineering..Wind Turbine Kits 500W - 5000W ~ F&P Dual Kits ~ GOE222Blades- Voltage Control Parts ------- Tower kits |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi Phill Thanks for that I also might try the blade tip modification to get the blade tip loading up a bit and stay with the smaller diameter blades to help speed them up a bit, any thoughts on the AA of the blades for running a bit faster? Have you tried a slightly lower AA say 6 deg instead of 8 deg. All the best Bob Foolin Around |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi All I finally got the mill up and running, now I have to wait for some wind to give it a real assessment so far I have had a slight breeze around 2ms according to my hand held device, this is enough to spin up the blades and generate 50 watts into the GTI for a couple of gusts it went into charge battery mode an additional 90 watts. Considering it is mounted on the roof of the shed 3 meter above the roof its not the ideal wind catching position, but it is so far exceeding expectations as the other mill on the roof hasn't generated anything in the same conditions. Up close on the roof it looks big but once down on the ground it can be hardly seen, even with my glasses on.

Looking across the roof to the west you can see the trees in the background these are 90 meters from the mill but still cause some turbulence, most wind of any note comes from the south and that is relatively relatively clear as you can see right down south to th great dividing range some 90 Klm away.

This is the view from the ground note the trees to the east where the sea breeze comes in, they cause a lot of turbulence but the wind speed from the east is usually below 5 ms more work required.

This is the mast and rotator prior to fitting the generator, I made a platform to work off so its not as bad as it looks, except when standing on the top of the stepladder trying to feed the wires through the mounting with one hand while holding the turbine in the other hand, one leg wrapped around the mast like a possum to avoid the acceleration of gravity

All in all it was a bit of a trying job to get it up there but the results are well worth the effort. The project took a bit longer than anticipated due to a few days sick and getting bitten by a snake while mowing the lawn, my wife thinks I am crazy and I am inclined to agree on that one. I will post the work done on the generator and blades for a matter of interest as long as I don't bore you all to death . All the best Bob Foolin Around |

||||

| kevindion Regular Member Joined: 28/07/2010 Location: ChinaPosts: 59 |

can you tell me the chinese company's name?i cann't find this type of blades in here. |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi Kevin Fillm gets the extruded, so if you want some blades I suggest you give him a PM and he may be able to help you. All the best Bob Foolin Around |

||||

| kevindion Regular Member Joined: 28/07/2010 Location: ChinaPosts: 59 |

i just want to build a windmill for a friend befor i leave China,so ship blads from broad is crazy idea. i did plan to use pvc pipe and then spray photocatalyst on blades for keep them works well from UV,but i am not sure pvc blads can catch enough low-wind power. |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi Kevin I believe Phill gets them extruded in China, if you contact him he may be able to get them shipped direct to you there may be minimum shipping amounts however. They are excellent wind grabbing blades comparing to PVC pipe blades they start better and deliver a lot more power. All the best Bob Foolin Around |

||||

fillm Guru Joined: 10/02/2007 Location: AustraliaPosts: 730 |

Hi Bob, Good to see your mill up and flying and producing some power , I noticed on your pic that you have lengthened the tail with 3 sections , I dont know how heavy this has now made it. I usually connect a strainer wire from the top of the tail to one of the tail mount bolts on the pivot with a small turn buckle to take the weight. Did you change the furl pivot angles to suit your tail? Also with the blades pushed out to 2.8m I would strongly advise you to try star, in the wind we get here it will make more low down power and will load the blades better and virtually turns this mill silent with no blade noise. PhillM ...Oz Wind Engineering..Wind Turbine Kits 500W - 5000W ~ F&P Dual Kits ~ GOE222Blades- Voltage Control Parts ------- Tower kits |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

`Hi Phill I haven't put the `tail wire in place yet as I have been playing with the tail a bit, had it off and on a couple of times, I put the extension in you recommended and shifted the vane out 10" but it still wouldn't track the wind at low speed , less than 1 ms so I pulled it down again and added the extension in the picture.

This morning it was tracking in wind to slow to measure, so all is well there. The blades are nearly silent so no problems there, When the generator cuts in at slow speed it grumbles a bit but as it comes up in speed the noise goes away. I think its the coil loading cogging at slow speed feeding down the gut wires into the tin roof, as if I unload the mill it goes away and is silent. Yesterday when the wind was just over 2 ms it was putting 6 amps into the GTI at 16 volts and on gusts it was going into battery charge mode as well, so I am very happy with the results. This means it was putting 300 watts into the grid and a few amps into the batteries at the same time, around 400 watts, not bad for below 3 ms.I might get another set of blades off you if you have spares and try the smaller original blades for a comparison. All the best Bob Foolin Around |

||||

| Greenbelt Guru Joined: 11/01/2009 Location: United StatesPosts: 566 |

Hi Bob; I've been watching your progress on the new mill and that was quick ! Anxious to see the 6 meter output and I love those extension on the blades. that Chinese gen seems to be excelent for light wind and you are now set up for the torque needed to turn it. Good Job and Hat Feathers for you and Phil. I can't Read Oz math?? I suspect You mean the wind Gusts were well over 3 ms to generate 400 watts while the measured wind speed was just under 3 ms." not bad for below 3 ms" ?? What am I missing??? BTW that last joke you posted was a hit with me, I could see the Doggies all patiently Waiting for the privilege to use the Tree, Just like people at the unemployment office waiting for their pittance Check. Cheers--Roe

"Yesterday when the wind was just over 2 ms it was putting 6 amps into the GTI at 16 volts and on gusts it was going into battery charge mode as well, so I am very happy with the results. This means it was putting 300 watts into the grid and a few amps into the batteries at the same time, around 400 watts, not bad for below 3 ms" Time has proven that I am blind to the Obvious, some of the above may be True? |

||||

| GWatPE Senior Member Joined: 01/09/2006 Location: AustraliaPosts: 2127 |

Hi Bob, I don't wish to be seen as too critical, but I have just run the numbers for your setup.

I think you must have very special air at your place to get 400W at below 3m/s for the rotor dimensions on the mill. I think you have some problems measuring windspeed. I spent significant effort correlating my own data logging prior to presenting results. I hope you are able to get your logging going, as the numbers you presented above are extremely optimistic. the wind energy is only about 100W @ 3m/s for the rotor. This is prior to blade and alternator efficiency, and you quote 4X more output to the loads. I just run the numbers and realize there is a problem with the data, but others not so experienced, reading this may take the data as it stands, and will be very dissappointed when the windmill does not produce proportionally more power for them in known winds at higher windspeeds. For those readers, not so informed, if the windspeed was increased to say 6m/s, [24kph], the windmill should produce 3200W. This is not out there extreme winds. I think it is important that if data is presented that it is at least checked to confirm that it is close to right. Gordon. become more energy aware |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi Roe At the moment my weather station battery has gone flat so must change it, the reading was with a hand held device while standing on the roof within a few feet of the mill, I didn't see the wind speed go over 3 ms while I was on the roof but Murphy's law comes into play for sure. As the mill is driving a GTI it is pretty well unloaded until the GTI synchronizes and it loads down a bit, It is far better than I anticipated, my old mill spins up in the same wind but doesn't generate enough to synchronize the GTI it is doing 10 volts AC while the new one is 18 AC volts. There is significant differences in the two blade profiles so it is comparing apples with oranges I suppose. When I get some better wind I will be able to give a better comparison between the two blade types. Glad you enjoy the joke section, it's good to have a laugh at things every now and then. All the best Bob Foolin Around |

||||

| Page 1 of 9 |

|||||