|

|

Forum Index : Windmills : Small Axial flux, what to do?

| Author | Message | ||||

| dazler Newbie Joined: 21/10/2007 Location: AustraliaPosts: 37 |

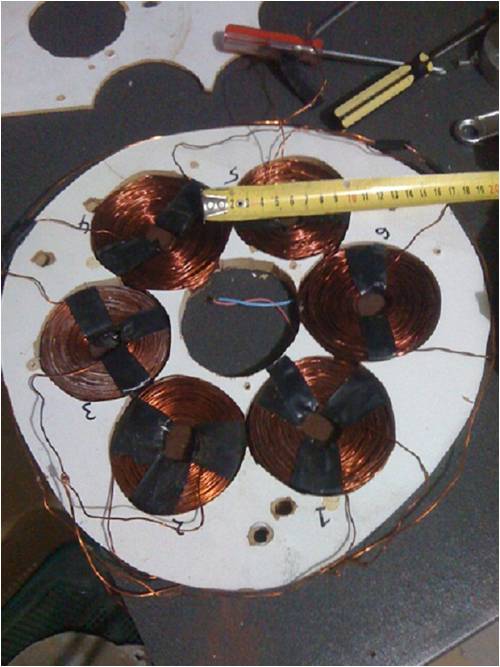

hi guys, i have made a small dual axial flux wind mill toy from 1mm wire from f&p 100s. the magnets are 20x15x10 neos. 6 coils in star and 8 magnets on a 200mm rotors. I could only get 5 to 6volts from it in high winds? do u think i could use a doulber to get more from this mill or different conf with the wire. pics below thanks

|

||||

MacGyver Guru Joined: 12/05/2009 Location: United StatesPosts: 1329 |

dazler You have made a valiant effort, but there are a few obvious (to me) problems. Let's start from the beginning here. It's not really starting over completely, but close to it. First off, it appears from your picture that your coils are far and away too large for the magnets. Another thing is, most folks try to match the shape of the coil to that of the magnet profile. Round will work, but in this case I believe you are "canceling" most of your charge. By that, I mean as the magnet face passes the coil from one side to the other, as it crosses the center, it induces a charge in the same wire, which on the other side is running the opposite direction relative to the magnet. This charge negates what was created on the other side. Let's do this: Build a test coil. Build it so it looks like your magnets (square) and no larger than the magnet's outside dimension. Next, get more magnets so the space between each magnet on each wheel (2 wheels, right?) is about half the width of one magnet. I must assume the "N" and "S" faces are on the flats, right? If the faces are on the ends or sides, we're in trouble. The face of the magnets must pass parallel to the plane in which the wire is wound. Rebuild your stator with more magnets and build one test coil and spin your two magnet wheels around the thing to get an accurate voltage from one single coil and we'll do more. That brings up another question: What is your inter-magnet space or "air gap"? I don't work in metrics and am used to inches. The magnets in your picture look about 1/2" thick. If this is true, the "air gap" should be twice the thickness times 75%. That means 2 x the thickness of one magnet x .75 = air gap. Try to get as close as possible to this figure for optimum output. Once you have determined the air gap, remember your coils will have to be wound no thicker than to leave about 1/16" space on each side of the stator for the magnets to whirl past. Make these changes and post your results and we'll go on from there. If it's any consolation, I too make very tiny projects and have pulled most of my hair out figuring a way to make a tiny axial-flux wind alternator and I'll tell you straight up: It ain't no easy project!!! . . . . . Mac Nothing difficult is ever easy! Perhaps better stated in the words of Morgan Freeman, "Where there is no struggle, there is no progress!" Copeville, Texas |

||||

niall1 Senior Member Joined: 20/11/2008 Location: IrelandPosts: 331 |

hi Dazler i,d agree with Macs points...the power of the available mag size and coil layout seems pretty crucial... your stator is similar to one of mine..on mine though i guessed the turn count per coil and made a complete hames of it...i had far too many turns of thin wire per coil...a bit off a dog...  ... ...

the only way i could get anything out of it was to set it up as a kind of odd single phase and take advantage off the extra magnet power...it was fairly forgiving in the end , and a better match to the prop than i thought it would be .... single phase can give a lot of wiring options that can sometimes get you out of a hole....but its a kind of a last resort ..it results in a pulsing stator which will do its best to try to shake itself apart....

heres a link to another 8 mag 6 coil machine..theres some pics further down the page of that machine ...keep at it and well done salvaging the wire for the experiment http://fieldlines.com/board/index.php?PHPSESSID=344b3b38bae7 192dbb9d2f79a62e1bc3&topic=140030.0 niall |

||||

| dazler Newbie Joined: 21/10/2007 Location: AustraliaPosts: 37 |

Hi Mac, i will get it set up again and play around with some test coils. yes 2 rotors 8 mags each. and both rotors N S N S N S N S. I hear what ur saying about to much wire. i first made a stator with .8mm wire 70 turns same rotors, but no luck less volts may be 1 or 1.5 . Question if had small wire say .6 or .8 instead of 1mm could this help? The set up "air gap" was 3mm each side of stator and the 6 coils are 12mm thick. also the blades where 850mm total but spin very fast about 400 to 500rpm. ok i'll have a play and come back to u on this. cheers Darren |

||||

| dazler Newbie Joined: 21/10/2007 Location: AustraliaPosts: 37 |

Hi nails thanks , i thing that the trouble u had was the number of coils to mags. 7 to 14 yeh. as the ideal combo is 3/4 6 coils to 8 mags or 9 to 12. its all about having fun

cheers |

||||

| itsandbits1 Regular Member Joined: 13/08/2010 Location: CanadaPosts: 81 |

yes the hole in the coil needs to be bigger than the magnet so that the flux is leaving one side as it starts in on the other. you also want your magnet gap closed up so the north is coming in as the south is leaving and vice versa. and also I think you need to have an odd # magnets or coils I think, I forget which. All these not proper will cause the effect to cancell out |

||||

| dazler Newbie Joined: 21/10/2007 Location: AustraliaPosts: 37 |

Hi Mac, I've done some coil testing, the findings: the big coils above got 1.3 volt dc but had no room (was hit all tread) the middle size 1mm wire 95 turns got .75vdc the small one got .5vdc the new magnet set out on rotors is set up for the two small test coils. and i tested the old set up using the big coil and mags on the rotor out to edges (same as in first post) and got 1vdc. also i was thinking about 12 mag 9 coil setup. coils of the 95turns, rotor1 with 12 mags on and rotor2 with no as i dont have 24 mags just 16? cheers |

||||

Downwind Guru Joined: 09/09/2009 Location: AustraliaPosts: 2333 |

Now that looks like regenative braking on the gokart there.

For starters you quote VDC....no wonder your voltage dont make any sense, you need the meter set to VAC, as it is AC volts the coil will produce. Your coils also look too big in diameter for you magnet sizes. I think you are trying to make the same mistake as many, with wanting to get more out than you are able to get. Basically you are govenerd by your magnet size, (NO IF OR BUTS,) and trying to make the difference up with oversized coils just wont work and will go from bad to worst. Do the test again with the meter set to AC, then try putting 2 magnets end to end to double the length and test again, it should give a better result. Pete. Sometimes it just works |

||||

niall1 Senior Member Joined: 20/11/2008 Location: IrelandPosts: 331 |

hi Dazler in your last pic the magnet surface area is starting to match the coil leg width...this seems a good thing although moving in the mags on the rotor will leave a lot less room to fit in the coils....i think matching the coil diameter like Pete said is the optimum goal like you said ...its fun....

the mags look pretty thick...i think a good guide line used by people who have trodden this path is that the rotor disk thickness should be at least the same as the mags...that seems to focus the available power to its best effect ...every bit helps in the scheme off things if you try putting 2 mags end to end you can still use the empty second rotating disk as a focal point to suck the power through the coils ... niall |

||||

MacGyver Guru Joined: 12/05/2009 Location: United StatesPosts: 1329 |

dazler Okay, lets get down to brass tacks. What you need to do is start over and go step by step to get some real results. For starters, here are some "rules" (read that guidelines): Measure your magnets' thickness. Double that and multiply by 75% (0.75). The result is your "ideal" air gap. From the picture yours looks kind of large (like twice as large as it might should be!). Next, wind your coils to more match the shape of your magnets. Round will work, but the more it appears to take the shape of a "flimish" (spiral, which almost fills the entire area), the more "cancellation" will occur and you'll wind up with next to nothing for voltage. Yes, your meter needs to be set on VAC (volts - alternating current). If there are multiple settings, study the scales and choose the lowest one for starters. If it's too much voltage, you can click up to the next setting, but likely as not, you'll not need a scale over 10 volts a.c. Make sure your magnets are provided with enough "flux-return path". Try sticking a small metal paper clip to the back side of the magnets, where they are attached to the metal plate. If the paper clip sticks (magnetically), you need thicker plates. If it falls off, you're okay there. Remember that flux needs to have a complete circuit just the same as an electric circuit does. Once you have the proper magnet backing and air gap, use any coil you know the number of turns of that fits the gap without hitting stuff and spin up the wheels together at approximately 300 to 400 rpm. This is a good "cut-in" speed to shoot for. At that speed, measure the voltage. Next, divide the number of turns on the coil by the voltage and you will get the "turns per volt". This is an important number; jot it down somewhere! Here's a hint or maybe a "goal": If you are going to make this a 3-phase alternator that will charge a 12-volt battery, the phase windings will have to be 120* apart from each other. With 8 magnets, it's likely all you'll be able to shoot for is single phase. A 3-phase application should have 9 coils and 12 magnets (3:4 coil to magnet ratio) and a per-coil voltage of around 1.8. For a single phase application, it should be more on the order of 2 volts. Either of these combinations will produce about 13 volts. If it's true 3-phase you get the final voltage by volts-per-coil x 1.4 x1.7 (star), but we'll get to that later. There are several ways to wind and connect coils and each produces a different outcome; lots of trade-offs in this game. For now, it would be nice to know what kind of voltage and current you are after. Knowing that, we can work the math backwards and get to what you need at the proper cut-in rate and make something that will actually work right out of the chute. Doing it in the blind is just that. If you don't have a definite goal and stick to the playing rules, it's like what Forest Gump said about life being like a box of chocolates; you never know what you're gonna get! Do all this and then get back to us here and we'll go to the next level. . . . . . Mac Nothing difficult is ever easy! Perhaps better stated in the words of Morgan Freeman, "Where there is no struggle, there is no progress!" Copeville, Texas |

||||

| dazler Newbie Joined: 21/10/2007 Location: AustraliaPosts: 37 |

Thanks guys for the help. yes i was using vdc through a ac to dc thing, ok my meter dose say its ac V~  this time meter hooked straght to coil wires. this time meter hooked straght to coil wires.

which the big one max reading is 2.0vac and 95turns is 1.5 and small one is 1.1. but i will get a better meter to check. "small metal paper clip to the back side of the magnets, where they are attached to the metal plate. If the paper clip sticks (magnetically), you need thicker plates." thats all good it falls to the floor. mac im tring to charge a 12v 7ah battery (kids toy car) also the mags are 20mm x 15mm x 10mm think and air gap 20mm about from mag face to face inside. thanks guys |

||||

MacGyver Guru Joined: 12/05/2009 Location: United StatesPosts: 1329 |

dazler Good news about the paper clip. Now, I should tell you we are going about this kinda backwards. If we were smart, we'd choose a blade and a cut-in speed first. Without that information, we could build and build and not really have anything that will give us good results when we're done. I chose 300 to 400 rpm cut-in arbitrarily, because most machines use this range, but it's not written in stone. There's a thing called "Alton's Blade Chart" and I'll have to search for a link for you later. With that chart, we can choose a TSR (tip speed ratio) for the blade and wind force and get some meaningful information for our build. For now, let's work on the air gap question and come back to Alton's later. Metric is Martian to me, but I'll just flow with it. You say your magnets are 10mm thick, right? Double that and multiply by .75 and that is your ideal air gap, which by looking at my ruler that is metric and imperial both, that's about 9/16", a little over half an inch. If your air gap is any wider, you're wasting flux and will get poor induction at the coil (low voltage). Also, just use one coil for the test. Induction is "linear", meaning that it is directly proportional to number of turns at a given flux and rotational speed. Double the speed; double the voltage, etc. Having more than one coil is a waste of time and will get us all confused (been there; done that). Once you have the "turns-per-volt" figure, go with that. It'll mean the future coils will have to be made of the same gauge wire and same width to give the same results. The wire thickness can be changed to improve the amperage, but we'll get to that later on. What is your turns-per-volt number? . . . . . Mac Nothing difficult is ever easy! Perhaps better stated in the words of Morgan Freeman, "Where there is no struggle, there is no progress!" Copeville, Texas |

||||

MacGyver Guru Joined: 12/05/2009 Location: United StatesPosts: 1329 |

Alton's Calculator Use this Link to view a chart that will calculate stuff for your build. . . . . . Mac Nothing difficult is ever easy! Perhaps better stated in the words of Morgan Freeman, "Where there is no struggle, there is no progress!" Copeville, Texas |

||||

| dazler Newbie Joined: 21/10/2007 Location: AustraliaPosts: 37 |

Hi Mac, "Next, divide the number of turns on the coil by the voltage and you will get the "turns per volt". This is an important number; jot it down somewhere! " 95 turns / 1.5v =63.33 turns per volt. are u saying if i want 2volts i need 126 turns

also Martian talk... 2 mm just over 1/16" 3 mm just over 3/32" 4 mm just over 1/8" 5 mm 3/16" 6 mm just under 1/4" 7 mm just over 1/4" 8 mm 5/16" 9 mm just under 3/8" 10 mm just over 3/8" 11 mm 7/16" 12 mm just under 1/2" 13 mm just over 1/2" 14 mm just under 9/16" 15 mm just under 5/8" 16 mm 5/8" 17 mm just under 11/16" 18 mm just under 3/4" so the air gap in inches are 3/8 *2 *3/4=??

cheers daz |

||||

MacGyver Guru Joined: 12/05/2009 Location: United StatesPosts: 1329 |

[Quote=dazler]95 turns / 1.5v =63.33 turns per volt. are u saying if i want 2volts i need 126 turns Yup! Or pretty near that amount. Since it is a tich over 63 I'd go maybe 65 and that doubled to 130 to be on the safe side; hidden losses and all ya know. Also, instead of using quotes, the forum standard is to stick it in a little box, like I've done your quote above. To do that, click on the "Forum Codes" link at the bottom of the Post Reply box and scroll down to the one that says "Quoting". Choose the first option of the two listed. Copy and paste it into the body of your reply and then change out the information for Username and Quoted Message With Username by the copy / delete / paste method. Doing it this way keeps the board more uniform and everyone gets used to the same format. It makes reading and searching easier for folks. As for the Martian derivations, thanks, but at my age I don't see any point in committing them to memory, so I'll just stick to imperial measurements. That old saying, "You can't teach an old dog new tricks" may have something to do with it, I dunno. . . . . . Mac Nothing difficult is ever easy! Perhaps better stated in the words of Morgan Freeman, "Where there is no struggle, there is no progress!" Copeville, Texas |

||||

| JA Robby Newbie Joined: 20/07/2010 Location: JamaicaPosts: 13 |

HI everyone, Would this setup still be consider a three phase? How would you connect the coils? very interesting. JA robby No man is an island. |

||||

MacGyver Guru Joined: 12/05/2009 Location: United StatesPosts: 1329 |

[Quote=JA Robby]Would this setup still be consider a three phase? How would you connect the coils? Not necessarily, but it could be wired that way. To do it 3-phase, using the 6 coils, two adjacent coils would have to be connected in series and then all three coil pairs would have one common lead and three separate individual connections at the "star" point. That's a total of four wires; one from each coil pair and a common. It could be all six coils in series for that matter and that would be single phase, but that has its own set of problems. I made one with 6 coils and it works, but not very well. Nine coils and 12 magnets is a better combination. That way three sets of 3 coils are each 120* apart (3 x 120* = 360*) and that's the gold standard. . . . . . . Mac Nothing difficult is ever easy! Perhaps better stated in the words of Morgan Freeman, "Where there is no struggle, there is no progress!" Copeville, Texas |

||||