|

|

Forum Index : Windmills : Fibreglass windmill blades

| Page 1 of 2 |

|||||

| Author | Message | ||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

I'm working with Trev to design a set of fibreglass windmill blades. We want these blades to be the "ideal" set of blades for a F&P or similar sized alternator. Once the design is complete, if we get enough interest Trev will be able to supply them as a set for sale. To keep costs down, the blades would most likely be sold as unfinished, meaning the buyer would need to clean up the edges, sand and paint. What we need is some info on the best airfoil to use ( or even a dxf file ), diameter ( 2.2 meter, 2.4, etc ), tsr, etc. Any info would be appreciated. Currently there are no reasonably priced blades of this size on the market. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| brucedownunder2 Guru Joined: 14/09/2005 Location: AustraliaPosts: 1548 |

Hi guys, well,from my experience looking out the back yard at my 11 footer, i'd go for a 13 footer that maybe you could cut down a bit if you want. mine is looking good,but in light winds it just gets up to that magic V point of 28-30 v and then hasen't got the grunt to keep rising -if you know what I mean. I'd also go for something around 10 inches at the root tapering to ,say, 3.5 inches at the tip. For the F&P ,I'm now fairly sure that 2:1 belt drive is a goer- any more and it will not start in less than moderate winds-oh, and by the way ,I use a Neo magnet rotor. So, this is why I suggest a 13 foot blade, to get the "turning power" I have a spare 5 foot 6 inch copy of my blades,if you like i'd do a deal with you ,so you can copy it ,extend it, Etc. Bruce Bushboy |

||||

| peter Newbie Joined: 15/01/2006 Location: AustraliaPosts: 25 |

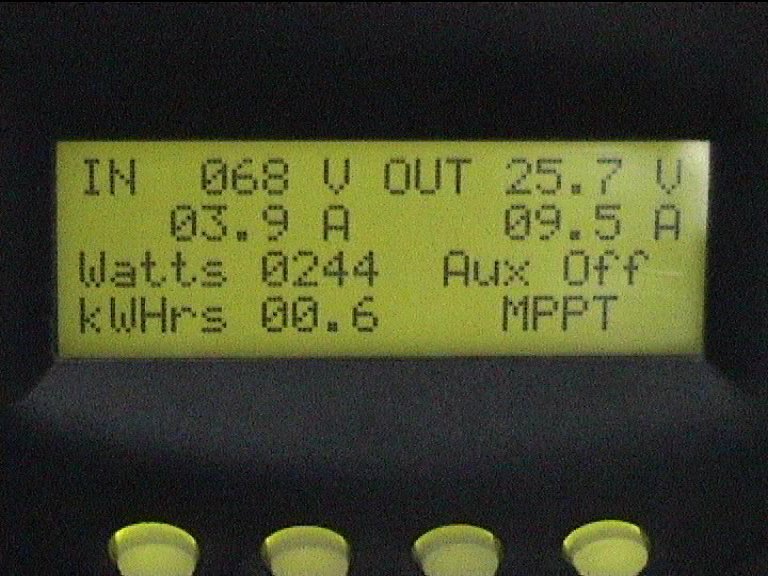

great idea there is a real need for them I have blades similar in length to Bush boy's 1.8 metre long 250mm at root 95mm at the tip carved on a duplicating machine using a modified NACA4412 profile. they provide plenty of "grunt"

wind output at about 8m/s

solar output... a bit overcast  [ [

flying  |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

Bruce, you and your inches and feet. I had to grab the old calculator to convert it to "real" measurements.

Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| petanque don Senior Member Joined: 02/08/2006 Location: AustraliaPosts: 212 |

While I have only modest experience would not any design be a compromise between Low wind speed performance. High wind speed performance. Performance on “smooth” wind. Performance in turbulent conditions. And probably several other parameters. What criteria would be most important would depend on environmental and personal situation. Won’t any practical design poses some compromise to make it suitable for all round use? Certainly the concept of having a product available off the shelf I think is great and the potential to gain economies of scale from longer production runs because of the high fixed costs is enormous. I will start to sound like an economist. Great idea Don |

||||

| RossW Guru Joined: 25/02/2006 Location: AustraliaPosts: 495 |

Ahh, but wouldn't some *properly made* blades, of high quality and good finish, nicely balanced and made of suitable material *PROBABLY* outperform the majority of home-made blades? I mean, a "near perfect" blade thats optimised for slightly different conditions will probably work as well as (or better than) a "less than perfect" blade that IS optimised for the sites conditions? Swings and roundabouts, me thinks :) Count me in if I can get one of those nicely made cast hubs, machined to suit, and a set of blades! |

||||

| AllanS Regular Member Joined: 05/06/2006 Location: Posts: 67 |

http://warlock.com.au/wind.htm It's probably been mentioned elsewhere, but these blokes have made their own fibreglass blades, and the site has a handy profile calculator too. |

||||

| dwyer Guru Joined: 19/09/2005 Location: AustraliaPosts: 574 |

Hi Alan  I have already gave this information about Warlock.com.au on MY 2 Cents on 6 of March this year as l guess they all have forgot about it I have already gave this information about Warlock.com.au on MY 2 Cents on 6 of March this year as l guess they all have forgot about it

dwyer the bushman |

||||

| AllanS Regular Member Joined: 05/06/2006 Location: Posts: 67 |

Ah Dwyer, Genius is rarely appreciated, as I know only too well. |

||||

| petanque don Senior Member Joined: 02/08/2006 Location: AustraliaPosts: 212 |

I would think that they certainly would. But more importantly is the potential to save people time. Equally there may even be people that making the blades would put the project in the “to hard” basket and having the specialised parts available could encourage them to have a go. |

||||

| RossW Guru Joined: 25/02/2006 Location: AustraliaPosts: 495 |

While I have only modest experience would not any design be a compromise between (list) Won’t any practical design poses some compromise to make it suitable for all round use? Certainly the concept of having a product available off the shelf I think is great and the potential to gain economies of scale from longer production runs because of the high fixed costs is enormous. Ahh, but wouldn't some *properly made* blades, of high quality and good finish, nicely balanced and made of suitable material *PROBABLY* outperform the majority of home-made blades? I would think that they certainly would. But more importantly is the potential to save people time. Equally there may even be people that making the blades would put the project in the “to hard” basket and having the specialised parts available could encourage them to have a go. I know, from my own point of view, making blades from scratch is beyond my capacity - I don't have the workshop space at the moment to do it, nor the time to do it. I'm happy to do a little bit as I get time, but carving a decent set of blades would (and has to date) eliminated the possibility of me making my own (which is the main reason I purchased this 1KW chineese thing - it was all done, just needed put up!) I'm sure if there were a reasonably priced kit available, there would be a lot more takers! Also, if anyone has plans to make a VAWT kit at some stage in the near future, I'd be really keen to try that too! My interest is driven by need rather than just something to "tinker" with, and as such a 48V system capable of a minimum of 500W would be my "starting point". Any smaller is unfortunately, just not worth my effort. |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

Yeah I'm the same when it comes to carving blades. I've only ever made one set, from ply wood, with no twist. I did attempt to make a set using the correct profile and twist, but it took so long to make just one blade, that I gave up. I could never get the next two blades the same as the first. Lucky for me I ended up with a set of blades carved by Dennis Latham in Adelaide, very well made. I agree blade carving is one part of windmill construction that puts a lot of people off. Some of us are gifted when it comes to shaping wood, I'm not, give me a lump of steel and a welder anyday. The NACA4412 profile Peter suggested is a good starting point I think, its got lots of space in the middle for strength, and a nice rounded nose.

There are two "calculators" I've used in the past, and both give different results. The work by Hugh ( www.scoraigwind.com ), and the Warlock calculator. Has anyone got an opinion on which would be better to use. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| milkwood Newbie Joined: 27/07/2006 Location: AustraliaPosts: 12 |

Glenn, I think this a great idea. I have fashioned some blades from PVC because they were easy to make and inexpensive. But I like the sound of the fibreglass blades. What sort of price point are you targetting for these blades? Any idea at this stage? Ronald |

||||

| milkwood Newbie Joined: 27/07/2006 Location: AustraliaPosts: 12 |

Just another thought. If the F&P rotor is changed to Neo magnets, does the rotor need to be larger? I think I read this somewhere, to cope with the more powerful magents. If so, it may be a good idea to have two "models" of the blades to cope withb std and Neo rotors. Ronald |

||||

| sangeff Newbie Joined: 05/11/2005 Location: AustraliaPosts: 29 |

Hello, I downloaded a pdf from a website that i can no longer remember, But it has a complete design for a sri lancan wind generator including fibreglass blades in two profiles one is the naca 4412 profile with a 1.7mt diameter the second is a 2mt blade using a k2 profile all the power curves and tip speed ratios are there and ive found it to be a handy reference, Ill email it to glen. Geoff |

||||

| brucedownunder2 Guru Joined: 14/09/2005 Location: AustraliaPosts: 1548 |

Hey Trev and Glenn--- 1 thing I'd suggest is that you make the blades wide at the root and long,(so guys can cut them down a bit). I've got my 11 foot dia blades up and I think they could do with another couple inches wide at the root area. I'm fairly convinced that if you are in a marginal wind area then you need that bigger blade for these coggy F&P gennies. Oh, and on the same subject of low wind , make them as light as possible, a bit of flexing is ok , just angle the mill platform back from the tower Anything around 11 feet or more Dia needs to be mounted independently on a car hub,I reckon. Then the transmission can be by belt drive to the F&P shaft, this gives you room to experiment with gearing. Just my 2 bob's worth Bruce   Bushboy |

||||

Trev Guru Joined: 15/07/2006 Location: AustraliaPosts: 640 |

Already available are the fibreglass/composite blades, -1m long and 1.4m long making 2.1m and 2.9m diameter respectively. (Prop hubs also available.)I get very good performance from them (pics on the forum "Another f&p Windmill Builder, & just wrote a little in the forum about decogging, on these blades.) However, what we intend to do, is make blades with an aerofoil shape. The intention is to improve yet more with performance. Bruce, I have also experimented with the belt drive ratio, and my conclusion is that there is too much friction, therefore less driving force. This is why you need such large blades. The larger the blades, the greater the tip speed to any given rpm. Realistically, you end up with less rpm - hence the need for gearing - to get enough rpm for the thing to charge. I beleive the optimum is direct drive with the shortest posible blade length to keep the rpm, enough blade area to privide adequate driving force in low wind speeds. Increasing number of blades, increases blade area, so shoter blades can be used but the trade-off is more blades also reduces the rpm. I could give a lot more here, but I think you get some idea. Trev @ drivebynature.com |

||||

| Renman Newbie Joined: 24/09/2006 Location: United StatesPosts: 9 |

Hello from central Illinois. Newbie here with limited electrical knowledge. I have been ready about the F&P stator and for that matter everything I can on this forum about windpower, and have been in contact with Randy at Randy Workshop. What I am interseted in doing is of course building my own system and using it to supply as much of my power needs. Our home eats about 3200 KW per month. As Ross said: My interest is driven by need rather than just something to "tinker" with, and as such a 48V system capable of a minimum of 500W would be my "starting point". Any smaller is unfortunately, just not worth my effort. I would also like to just build a windpower station and use it without tinkering myself into oblivion. I have way to many projects going now. Just a few questions: 1. If you Decog an F&P stator you loose a little power is what I am reading. If you increase the blade size you overcome the F&Ps cogging problem and keep your power output. In a recent post Trevor & Glenn where talking about the fabrication of fiberglass blades. Has this happened and are they going to be optimized in size to take full advantage of the power output of the F&P unit? 2. At the otherpower site there isnt much mention of using the F&P stators. Everything I read on there site about windpower units are from my understanding, handmade units,some capable of generating alot of energy.Is it because the F&P units are capable of only so much wattage and this is the limiting factor for those individuals looking to create a system to sustain there needs? Just trying to learn. Great forum and I really am learning a lot. Thanks. Cliff RENMAN |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

Hi Cliff. Trev and myself havn't had a chance to get together to discuss the fibreglass blades yet. Dennis from Adelaide will be visiting us in early November, and he has been developing large PVC blades to a point where they are a cheap alternative to fibreglass or timber. So in a couple of months we should have some good blade designs. You dont hear much about the F&P on fieldlines because its mainly an American based forum, and the F&P are as rare as hens teeth in the USA, where here in Oz they are very easy to get hold of. But interrest in the F&P is starting to show on fieldlines thanks to guys like Randy's Workshop. I'm not a big fan of their home made axial alternators. The design originated as a way to reduce cogging, but has introduced its own problem ( heat in the coils, expensive magnets, magnets falling off due to poor epoxy/rust ). But that said, the design does work and can be scaled up to suit your needs. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| Renman Newbie Joined: 24/09/2006 Location: United StatesPosts: 9 |

Thanks for responding Glenn. I was searching Fieldlines using Fisher Pakel. Just a few moment ago I searched using F&P and found a number of discussions, so I will look these over before I post anything further. I will say that there is a certain "elegance of economy" that seems to exist in the mindset of the guys that post here on Backshed. Simple is most always better. Cliff RENMAN |

||||

| Page 1 of 2 |

|||||