|

|

Forum Index : Windmills : Slip rings from hardware store bits

| Author | Message | ||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

Hi Guys. I've been working on a windmill slip ring design built around common hardware store components. I wanted a design that was simple to make with no special tools and used easy to find parts. I've gone for a brass brush on a steel slipring. This combination may not be the best low resistance materials to use, but....

This is what I've come up with so far. The slip rings were made from some scrap zink plated steel I rolled and welded to make a ring. Exhaust tube would be easier, but I used what I had in my scrap pile. I drilled 3 holes at 120deg and a extra hole as the contact.

Two rings were made, and supported on 3 timber spacers around the windmill mast. The timber would be fixed to the mast with screws or hose clamps.

I have 2 versions of the brush holders. The first one uses 2 layers of steel strap ( used for packing, its very springy ). Each slip ring has two brass screws on opposite sides to ensure a good contact. Power it connected at the brass screw, I didnt want to use the strap to carry current.

And this design uses door hinges and springs instead of steel strap.

Both designs have a lot of give, so no matter how much I wiggled the windmill nacelle around, the brushes kept a good contact with the slip rings. So, before I put this hardware store slip ring into a web page for others to use, does anyone have any idea's or can see a problem with my designs? I'm open to suggestions. In the web page I would mention the obvious, ie waterproof the timber, put a cover over the whole thing, etc. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| KarlJ Guru Joined: 19/05/2008 Location: AustraliaPosts: 1178 |

going to get busy, sending 3 phases from two stators down the pole! Luck favours the well prepared |

||||

Downwind Guru Joined: 09/09/2009 Location: AustraliaPosts: 2333 |

Maybe a section of 100mm pvc sewer pipe inside the rings and a few pop rivets to secure them in place would give a optical pleasing look not that it would work any better. The only concern that comes to mind is --- Have you just built a fire starter?? I know it shouldnt, but it could do? I done a slip ring some years ago for a mini mill and etched some rings on a disc of pcb with some spring metal fingers dragging on the copper rings and this has worked fine for years. Ok not good enough to handle the current these mills generate, but 2 flat rings (one inside the other )are easy to mount and to work with. The hard part is cutting them out without distorting the metal. Thinking about it there is no reason why some heavy copper sheet could not be stuck to some fiberglass backing or heavy plastic and a layer of contact stuck over the copper. With the contact cut out where the copper was not wanted and the rings etched as you would a circuit board. The centre of the rings is cut out to allow the pole to slide through with a spacer on top and a second plate over that with the friction fingers attached to it.(brushes) The top plate is fixed to the mill head and the plate with the rings attached to the tower. The rings would sit 90 deg to the tower and not parallel as Glenn's is. Dont know if this makes sense. Pete. Sometimes it just works |

||||

| Janne Senior Member Joined: 20/06/2008 Location: FinlandPosts: 121 |

If the brass won't eat through the zink plating, and the combination of 2 different metals in contact won't cause corrosion.. Might even work =) Brass pipe and brushes are also not very hard to come by... If i ever went to sliprings in the yaw bearing, I definitely would use materials which I would be sure not to cause any problems along the way. But I'm sure the sliprings will have an easier life in Australia, than in here. IMHO, pendat cable down the tower is the number 1 choice, if the site is not very turbulent. It could be that the windsites of my machines have been less turbulent, than average, but i've never had much problems with cable twisting. I'd suspect the sliprings would be more trouble than good here. (sorry for going a bit offtopic here.) If at first you don't succeed, try again. My projects |

||||

| brucedownunder2 Guru Joined: 14/09/2005 Location: AustraliaPosts: 1548 |

Hello Glenn and all forum Members,, gee ,must have been one of the first projects I did ,,10-15 years ago ,,SlipRings.. I started with 3 inch copper sewerage pipe cut into weddin rings 1/4 inch wide. Then equal spaced these around the bearing hub of the underside of the yaw mounting car axle assembly. got them fairly accurate by inerting "chop-sticks"and pouring polester rein in the surounding gaps. Next came the brushes,,scrounged from vacumn cleaners and stff like that Mounted 2 per ring and insulated them from the steelwork.. Worked OK ,,but the resistance was far too high.. Haven't given up ,,will re-visit that one day,,,,LOL. Good to hear from your idea ,Glenn.Happy house hunting.. I wish all on the forum a very Merry Christmas and a Happy New Year.... Bruce... Bushboy |

||||

| brucedownunder2 Guru Joined: 14/09/2005 Location: AustraliaPosts: 1548 |

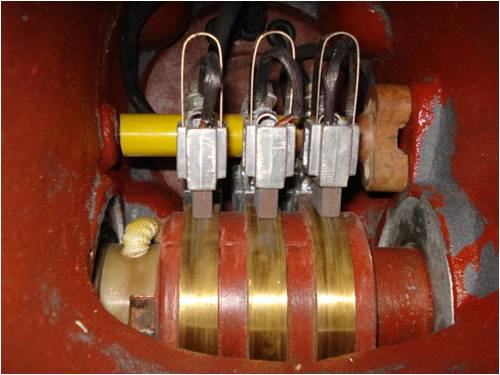

Hi guys ,just got a new gennie ,an Exmork 2.5 Kw machine with 3.8 Mtr blade set. I photographed the slipring assembly ,,so I thought you may be interested. Bruce Bushboy |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

Hey Bruce Nice looking set of sliprings. They look a good size too. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

RevUpWind Regular Member Joined: 03/05/2008 Location: AustraliaPosts: 60 |

Bruce those are great lookin slip rings and back up all I've read about Exmork turbines. All comments say they are very sturdily and heavily made, ie. strong castings, bearings etc. Noted some prices direct out of China and huge difference to what is now being sold in WA and agent in QLD. There is a micro link swivel connector I saw online which I believe are expensive and not sure if they have enough capacity. Seem to recall 40amps or so. Has anyone tried these? Peter ....River Heads - Australia The wind blows wherever it wishes; you hear the sound it makes, but you do not know where it comes from or where it is going. |

||||

Trev Guru Joined: 15/07/2006 Location: AustraliaPosts: 640 |

Very Good Glenn, My only concern would be that the steel pipe will go rusty when the zinc wears off. Certainly a cheap backyard idea. Off Topic - Bruce, I love the way you write, such creativity, "sewerage pipe" for "weddin rings". Also I have looked at importing those Exmork Turbines, Good price but very heavy. Please, in another thread I would love to hear how that Exmork works. These photos are quite old, but I don't think I ever posted them before. Maybe someone can utilise some ideas from them too. These photo's are of the inside of my slip ring setup. The 4 pole is what I use on my own double F&P White Pointer. The standard White Pointer Kit only has 2 slip rings. Basicly it is bronze rings and bronze brushes. The rings are seperated by PVC pipe and the brush holders are Nylon but could be made from any plastic, just drilled plastic rod and treaded to screw into the outer aluminium casing. The only thing you don't see is the springs to keep brush tension on the ring. The springs are inside the brush holders. Trev @ drivebynature.com |

||||

| RossW Guru Joined: 25/02/2006 Location: AustraliaPosts: 495 |

If anyone else wants some, let me know - I've brought a few in and would be willing to do so again for The BackShed members if there's a demand. |

||||

| George Newbie Joined: 07/02/2010 Location: CanadaPosts: 8 |

Ross, I have had some correspondence with Exmork. They gave me an excellent price on both the turbine and shipping, so good in fact that it doesn't seem worth the savings of building my own turbine. I've requested more information, so far I haven't been able to get much information or reviews on the company. Any links or information you are able to share would be greatly appreciated. George George |

||||

| Bolty Regular Member Joined: 03/04/2008 Location: AustraliaPosts: 81 |

I do not wish to hijack this posting, so have added some comments about my Exmork under a new thread under windmills! |

||||

| sip ring Newbie Joined: 25/08/2010 Location: ChinaPosts: 2 |

Hi Guys, Hangzhou Prosper Mechanical & Electrical Technology Co., Ltd. here, the earliest and biggest professional manufacturer for slip rings and joysticks with good quality and low price in China. Can supply both OEM and ODM service for customers. We are also the partner for some famous abroad slip ring vendors like SERVOTECNICA S.p.A. / Morgan-Rekofa GmbH...... If any one interested to be our agency in Canada for selling slip rings please feel free to contact with me. Cindy +86 571 81996708 info@hzqs.com www.hzqs.com Professional Manfacturer / Excellent Quality / Competitive Price / Fast Delivery / Perfect After-sale Service... |

||||

Doug Regular Member Joined: 11/05/2010 Location: New ZealandPosts: 41 |

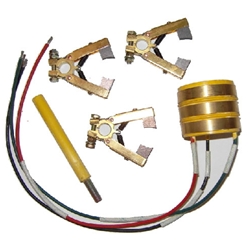

Hi all. Here's a shot of a slip ring set from EcoInnovation in new zealand. Looks very similar to the one's in the pic by Brucedownunder.

www.ecoinnovation.co.nz/p-267-slip-ring-and-brush-set.aspx"> May The Power Be With You |

||||

| brucedownunder2 Guru Joined: 14/09/2005 Location: AustraliaPosts: 1548 |

Yep , made a set long ago out of waste water pipe ,3inch and car brush holders .. A failure.. You have to really use chunky copper impregnated brushes and double up . Pictured are the Exmork slip rings ,,very sturdy and chunky ,thick cables ,and doubled up sets.

These are pictured on the side ,,rotate 90 to see the actual install Bruce Bushboy |

||||