|

|

Forum Index : Windmills : Accumulated power MPPT vs Battery charing

| Author | Message | ||||

| DaveP68 Senior Member Joined: 25/11/2014 Location: New ZealandPosts: 292 |

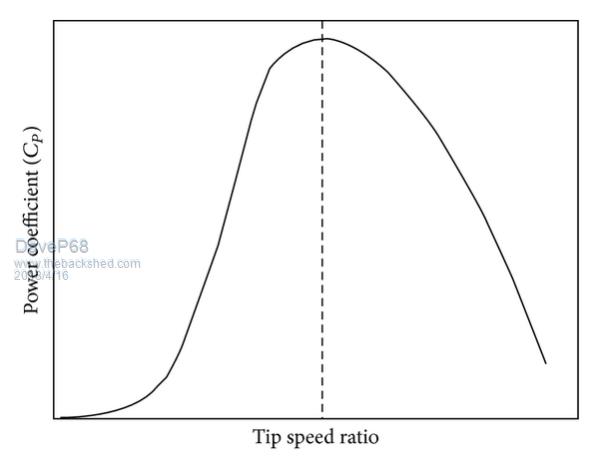

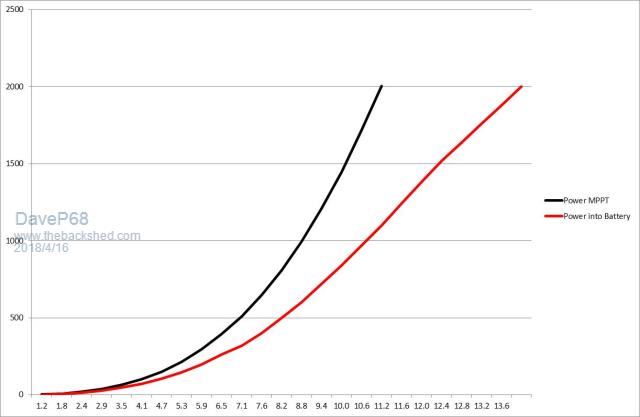

Would like to challenge the "myth" that there isn't much difference between MPPT and directly charging batteries in terms of the accumulated power each system produces. From careful analysis of factors like number of blades, blade TSR, shaft torque produced by blades and torque required to drive the PMA to provide a given output power. I have concluded there is a "minimum of 35% less accumulated power produced" when directly charging a battery in wind speed range 3 - 8 m/s vs MPPT. The torque produced by blades increases at a rate of 4x as the wind speed doubles. This will remain relatively constant if the blades are kept in their optimum TSR power coefficient (Cp). Tip Speed Ratio is directly related to Torque, please refer to the graph below.  If a PMA isn't correctly matched to blades with respect to the torque required to drive it, then energy will be lost. The current produced increases on a PMA at a rate of 6-8x as the RPM doubles if the voltage is clamped (by battery voltage). Torque is proportional to current drawn from a PMA. If torque is proportional to current the blades end up operating outside their optimum TSR with a 6-8x torque increase for a doubling of RPM. The big advantage of using MPPT is no matter what the blade TSR is, the torque taken by the PMA will be kept within the range of 4x increase as the RPM doubles. To put it simply MPPT allows PMA output voltage to increase over the operating RPM range to keep the current in proportion to required torque taken. Here is a graph of difference in performance between MPPT and Battery Charging.  The bottom scale m/s of wind vs power in watts. As you can clearly see the MPPT black line on the graph produces FAR more power at lower wind speeds resulting in more accumulated power produced.  There are realities if you do not accept, will lead to frustration because you will be spending time on wrong assumptions and the results cannot follow! The Dunning Kruger Effect :) |

||||

fillm Guru Joined: 10/02/2007 Location: AustraliaPosts: 730 |

Hi Dave, Congratulations and Great to here you finally have a wind turbine in the air, and with the ability to carefully analyse the data you are collecting in real world conditions to come to a point of your conclusion. Obviously you have cracked the holy grail and also built a wind MPPT charge controller. Would be good to see some pic's of your turbine and set-up? PhillM ...Oz Wind Engineering..Wind Turbine Kits 500W - 5000W ~ F&P Dual Kits ~ GOE222Blades- Voltage Control Parts ------- Tower kits |

||||

| isochronic Guru Joined: 21/01/2012 Location: AustraliaPosts: 689 |

I think some of the MPPT hype came from charging using a solar panel ie not a wind turbine |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

Control of solar with MPPT is pretty simple and a well proven technique, although these days solar panels are now so cheap, its easier to just add excess panels than try to scrape the last 1% with clever and sometimes expensive software. Wind turbines are a whole different game altogether. It too would be fairly straightforward if the wind speed was always steady and fairly constant, as it sometimes may be at some wind sites. The difficulty with MPPT comes with gusting and turbulence, and that there is a lag between what the Software tries to do, and the measured final result of any control change. Its always chasing its tail trying to correct, or over correct constantly varying conditions. That is the basic problem with any feedback system that involves appreciable delays between the control input, and the result as measured at the output. Control changes need to be made very slowly to avoid over correction or hunting. A totally different approach to controlling a wind turbine would be feed forward correction instead of feed back correction. If you can work out how much torque loading you can place on the turbine for every increasing step up in wind velocity, you will end up with a curve shape similar to those shown above. There will be an infinite number of different operating curve shapes for different combinations of blade shape, blade diameter, and number of blades. Different parts of the same blade will vary in efficiency along the blade, its not a simple linear effect. So what is needed is to test a particular turbine once installed in its final location, at various real measured wind speeds, and by experiment find out what duty cycle of PWM is required to achieve maximum charging current into a battery or whatever type of load is being powered. Its then a case of providing a lookup table "X" measured wind velocity to produce "Y" duty cycle in the wind machine controller. There need be no time delay or slow ramping, as the system can never over correct, hunt, or become unstable. It should respond pretty much instantly to sudden gusts so long as the anemometer can track very sudden gusts, as it should do easily. A system could be made to very gradually self learn over a long period by very slow modification of the stored lookup table. Normal operation would still rely directly on the stored lookup table for fast rapid control of the machine in real time. But it could slowly learn and improve its performance over time. A much simpler non learning system could be something as crude as a row of potentiometers. Each potentiometer corresponding to a range of measured wind speed. These could each be tweaked manually for optimum output. It would not be too difficult to improve on that, but its just suggested as a basic simple "starter" experiment for anyone interested in trying out this feed forward technique. Cheers, Tony. |

||||