|

|

Forum Index : Windmills : tower erection

| Page 1 of 2 |

|||||

| Author | Message | ||||

| brucedownunder2 Guru Joined: 14/09/2005 Location: AustraliaPosts: 1548 |

Hello , Well ,I'm stubborn. I'll have to admit ,I need help ,please. My tower bends so much when I lift it ,I'm too scared to go further . It's around 100x100x8 back to back bolted angle -structual steel.around 60 feet long . I have 3 wire ropes , through a couple of sheaved pulleys that ,I thought, would equalize the pullin/lifting load. All coming back to a single winch wire rope. The winch is strong enough-fine. My problem is , I start the lift and a bend developes about 3/4 way from the bottom of the tower length. I've tried moving the point -of-attachment wire ropes ,,helps to some degree . But really just moves the "bend" to a different area-tried many adjustments. So, I can,t lift my windgennie,which weighs around 80 kilos,all up . Would anyone with mechanical lifting experience be able to help . I live in the gold coast hinterland if that helps. Thank You Bruce Bushboy |

||||

fillm Guru Joined: 10/02/2007 Location: AustraliaPosts: 730 |

Hi Bruce, I am fairly busy at present but could probably come over to have a look in a week or 2 . You can give me a call if you want , you have my number. PhillM ...Oz Wind Engineering..Wind Turbine Kits 500W - 5000W ~ F&P Dual Kits ~ GOE222Blades- Voltage Control Parts ------- Tower kits |

||||

| brucedownunder2 Guru Joined: 14/09/2005 Location: AustraliaPosts: 1548 |

Thank You Phill , I'll do that . Stubborn old 73 yo ,but I now know I can,t do these things of yesterday. Bruce Bushboy |

||||

| Alastair Senior Member Joined: 03/04/2017 Location: AustraliaPosts: 161 |

Bruce, You already have several connection points by the sound of it. Years ago I used to help a guy who repaired windmills - usually bore pumps. Many of the towers were old and dodgy. He used large planks of wood under the wire at the connection points to spread the stress. Put the planks vertical and try to span as many structural members as you can. Cheers, Alastair |

||||

| brucedownunder2 Guru Joined: 14/09/2005 Location: AustraliaPosts: 1548 |

Thanks Alastair, This is a bit different , it,s not really a structual problem ,it's lifting the long single member length . It requires(I think) , support at intervals ,but the lifting cable has to have an equal lifting force equally along that length at the attachment points . How this is achieved is what I can't fathom .... Bruce Bushboy |

||||

| brucedownunder2 Guru Joined: 14/09/2005 Location: AustraliaPosts: 1548 |

picture of tower  hope this works OK, so the pic works, now , that is a pic of the old LIGHT F&P wind gennie,so the tower is able to be erected ok with that light load . Now I have a heavy 'er windgennie and it's heavier, so this is where the problem is . Not the lifting , but the bending of the steel.. I'll grab some pic's of the pulley block set-up later. Bruce Bushboy |

||||

| Alastair Senior Member Joined: 03/04/2017 Location: AustraliaPosts: 161 |

Bruce, I assumed it was a fabricated tower not a pole. Apologies. How heavy is the new generator? Cheers, Alastair |

||||

| brucedownunder2 Guru Joined: 14/09/2005 Location: AustraliaPosts: 1548 |

Hi Alastair, No need for apologies,just thankfull of your feedback ,it's what makes this forum tick. OK, weight ,it 's a Exmork 2 Kw chinese generator with fibreglass blades ,probably all up weight around 70 Kg. It takes a couple of us to fit first the generator to the mount ,then we fit the blades and tail. The steel is recovered TV tower structual steel of high quality and bolted with their special high tensile bolts together --sort of equal angle ,back to back . I've got it rigged with a huge winch ,which used to haul a 30 foot launch out of the brisbane river up a slipway,,so it's plenty strong with 8mm (3/8inch) wire hauling rope. it's been up and down 20 plus times since I built it ,I have it rigged so that it is a one man operation .can lower it in 3 minutes or so raise it in about the same time . so , thats about it, Bruce Bushboy |

||||

| brucedownunder2 Guru Joined: 14/09/2005 Location: AustraliaPosts: 1548 |

OK found a pic of the bending ,I'm talking about ,and you can see the attachment fixings on the tower steel -I've tried moving these fixings to other places ,but still get bending. by the way,these attached wire cables are actually one only ,going back to a sheave block . It is then pulled up tight by the winch cable.that may be where my problem is? Bruce  Bushboy |

||||

| yahoo2 Guru Joined: 05/04/2011 Location: AustraliaPosts: 1166 |

the topmost cable takes all the lifting weight, the lower ones are there to just stop things flopping around and hold the weight of the mast. if you are pulling on the lower cable the mast will bend. I think you have two options, use a gin pole or build a stiffer mast. Three options for a stiffer mast, large diameter thinwalled tube, lattice mast, or add outrigger stays to the centre section of the existing mast. I'm confused, no wait... maybe I'm not... |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

The crazy yacht guys have fairly similar problems raising the mast on a boat, and there are quite a few discussions and pictures on the internet about using shear legs to step a boat mast. However, your mast is a lot longer, and a lot heavier, especially with the wind machine mounted at the top. If I had to do this all by myself, I would also worry about getting it down again at some future date. As I am now almost seventy years old myself, I can really appreciate your situation. I think I might investigate getting a driller to bore a sixty foot deep hole and fit a a steel liner. Then lower each section down the hole and bolt the next section on top of the first, and so on. Then finally fitting the wind machine on top (at ground level). Then winch the whole thing up vertically slowly letting out the guy wires as it goes up. It could be lowered fairly quickly the same way for maintenance. If the whole thing is built vertical to start with, the bending problem is avoided altogether. Cheers, Tony. |

||||

| brucedownunder2 Guru Joined: 14/09/2005 Location: AustraliaPosts: 1548 |

Thank You Yahoo and Warpspeed for your ideas. The outriggers ,as in yacht "spreaders" seem to be the easiest way ,if it works ,no reason why not. As you said the most weight to lift is at the far end . When i lift it or lower it with the lighter windgennie on , it still bends , but once it gets ,say, 45 degrees,things start to straighten out and she is OK. but , of course,most of the weight now is in compression and the base is taking it. I tried several different attachment points, mostly trying to convince myself "she'll be allright" sort of mental thing. Phill is coming over when he's got time and we'll sort it out ,I'm sure. more important to get Ilda home at present , Bruce Bushboy |

||||

| yahoo2 Guru Joined: 05/04/2011 Location: AustraliaPosts: 1166 |

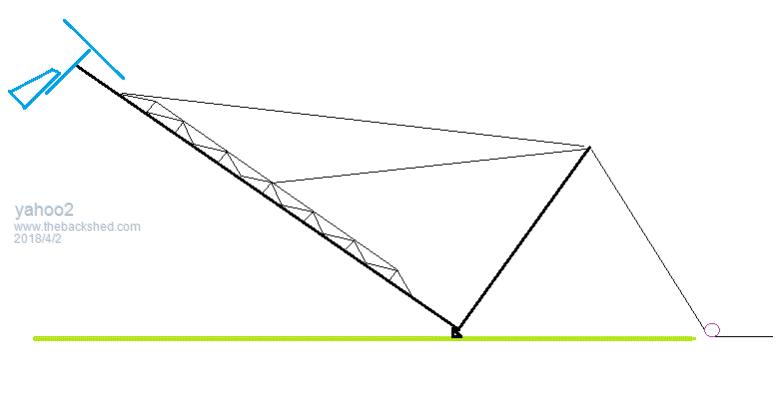

Yep Bruce, the problem with building stuff with metal is there is only strength in compression and tension, any metal that is on the central axis contributes nothing to stability in the other plane. That is why the stiff metal masts have a larger diameter and hollow centre (or triangular lattice), when they bend there is compression on one side and tension on the other.  I guess it is time for one of my matchstick man drawings again, the ones the search engines love so much. I guess it is time for one of my matchstick man drawings again, the ones the search engines love so much.   Ignore the zig-zag cross bracing, it does very little structurally under tension, as long as there is a triangle at both ends and the outrigger braces are there it will be all good. It would be even better with two outriggers 90 degrees apart tied in a triangle at the outrigger points. You can also see that the lift angles on the cables stay the same using a gin pole, it stops us pulling on the middle of the tower. Anyway, something for you to ponder and mull over, I have "dropped" a few towers over 100ft without the correct gear, that last 20-30 feet is pretty scary, it usually ends with something damaged. edit: Wow it looks much better on the interwebs! its no fusion360 but you get the idea. I'm confused, no wait... maybe I'm not... |

||||

| brucedownunder2 Guru Joined: 14/09/2005 Location: AustraliaPosts: 1548 |

Yes, the Jin pole method is certainly the preferred way to lift and lower. In my case , I erected a strong guyed vertical pole which I will call the stationary gin pole ,it's guyed and permanent. this then has pulley sheave blocks at the top and a couple metres down from the top. My lifting wire ropes go through these permanent stationary blocks and are then terminated on the tower to be lifted. So, in ordinary cases the gin pole moves from the ground up or from the vertical position to the ground. in my case nothing moves ,just the tower. I think less weight (the windgenerator+blades)would solve the problem , solution ,get rid of the lot and go solar. Bruce Bushboy |

||||

fillm Guru Joined: 10/02/2007 Location: AustraliaPosts: 730 |

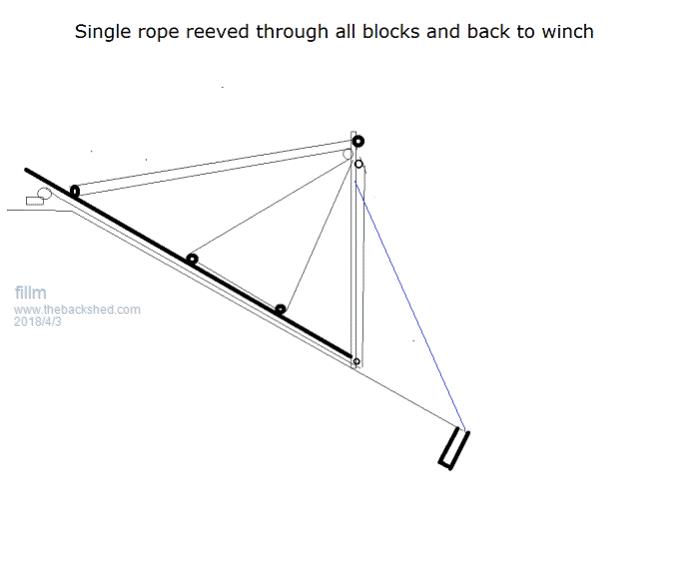

Bruce, Yahoo is correct an the method he has shown is the simplest and most cost effective way of raising turbine towers. As I know a little about your tower from visits many years ago, and from that and the pictures I can fairly well say that its not capable of a 80kg turbine without major modification . The lighter F&P were no problem in the day but now you have trippled the weight and extended the tower top with the 89mm ID Pipe . It is made from 75mm x 6 x 3mtr angle as you gave me a few pieces back then, I can not remember the full details of your build method but the best config is as a 20mm overlap stitch welded to give a + formation which give stability but still not as good as 100mm to 125mm pipe. Your lifting method is pulling on different radius points and if they are all 3 apear to be going back to the same winch drum. This will not work as different lengths will end up with the inner point getting ahead and the upper lagging a bending the tower as it appears now . The lifting method needs to be changed to the conventional "Gin Pole " this then has the frt guys permanently attached and as shown in Yahoo's drawing is pulled from one point and the weight of the pole assists the lift to the point of over counter balance at the top .. Or you could reeve as a single wire through wire rope pulleys and it would then pull evenly but the weight still might cause tower bending if the structure is flimsy with the 2kw on the end .  Also from your pictures you have raised the height of the tower with some 89mm pipe that looks to be just bolted in the first 1 - 2 mtr painted white and not moved the upper guy rope . This is most likelly also causing the upward bend in the under the guy point . The Upper guy point needs to be as close to the top as possible to minimize the unsupported, if you change this and also run the 3" 89mm pipe past the upper guy point it will then support the leverage exerted onto the upper section between the intermediate and upper guy point. I missed your call today but will catch up soon, there will be a solution. Tony Why you would want to wast copious amounts of money to sink a 60' encased bore hole so his tower can be raised and lowered like a tower crane is beyond compression to put a probably under 2kw turbine on . If its a space thing then stand alone tilt towers are available for up to 1 - 10kw turbines.They are the best solution for easy accessibility and no guy ropes. But the ground prep and concrete would not be as much as your idea and you undo a ring of bolts and winch it over . After looking at the cost most go back to the trusty guy tower and gin pole  PhillM ...Oz Wind Engineering..Wind Turbine Kits 500W - 5000W ~ F&P Dual Kits ~ GOE222Blades- Voltage Control Parts ------- Tower kits |

||||

| brucedownunder2 Guru Joined: 14/09/2005 Location: AustraliaPosts: 1548 |

Thanks Phill,. Tried calling you back ,but we'll catch up soon. Ilda is finally home and safe -drama has finished. the Tower, thanks for the illistrated drawing , my set up ie very similar,except for the addition of one extras sheeve block . This illistration works , but the friction in the intermediate placed sheeve blocks causes some difference in lifting forces. ( thats my guess ,anyhow) I don,t have any problem with the winch ,it's heaps strong enough . The weight of the 2Kw Gennie is a factor ,indeed. If I could just get the bending sorted out to some lesser degree,I think all would be OK , I reckon once it's up around 45 or more degrees it would behave itself ,up and down.. Ilda and I ,sometimes just myself , have raised and lowered this contraption many uneventfull times in the past -I carry a deadman up-down-stop control switch on a 60 metre lead around the paddock as we ,I, check all safety aspects while in operation . works perfectly . So, thanks again all of you for this discussion , Ilda is safely home at last after a very stressfull visit to her 102 year old Mum . Mums fine,. Bruce Bushboy |

||||

SparWeb Senior Member Joined: 17/04/2008 Location: CanadaPosts: 196 |

How close to the swing of the blades is this top guy wire attached? The photo you posted the other day makes it seem like there's at least a meter between the tip of the blade and the highest guy. Moving that up would make a big difference. The change in paint colour from white to green makes me think there's a joint there, too. If so that will contribute to the bending. Getting the guy wire attachment above all of the tube joints will also reduce the bending. The look of it though... it's still a heavy turbine for 100mm square tube. I'm not comfortable looking at that, like you are. I am also no fan of Exmorks, especially the 2KW model. I saw the aftermath of one that blew up - in a wind speed it should have survived. Steven T. Fahey |

||||

fillm Guru Joined: 10/02/2007 Location: AustraliaPosts: 730 |

Those are all valid points that I did also point to as well. Apart from that I take it the "Blew Up" is a fairly explicit description, would it mean the fibreglass blades delaminated as many do and may have bought the tower down? In general these type of 1 ~ 2.5 kw turbines are of very robust construction except for the blades and easily outlast much more expensive overpriced but now bankrupt manufacturers. . PhillM ...Oz Wind Engineering..Wind Turbine Kits 500W - 5000W ~ F&P Dual Kits ~ GOE222Blades- Voltage Control Parts ------- Tower kits |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

[quote]Tony Why you would want to wast copious amounts of money to sink a 60' encased bore hole so his tower can be raised and lowered like a tower crane is beyond compression to put a probably under 2kw turbine on . If its a space thing then stand alone tilt towers are available for up to 1 - 10kw turbines.They are the best solution for easy accessibility and no guy ropes. But the ground prep and concrete would not be as much as your idea[/quote] What you say is all very true. Any robust/reliable/safe method is not going to be cheap anyway, if everything is bought brand new and then professionally installed. But some of us can get lucky sometimes, or have access to materials or services (mates in the trade) that most other people do not. I do not know of anyone that has actually dug a deep bore hole to raise a fully assembled mast, it was put forward only as a theoretical suggestion, of being one possible solution to get right around the whole bending and high weight problem. It would also be a very safe way to do it. Cheers, Tony. |

||||

| brucedownunder2 Guru Joined: 14/09/2005 Location: AustraliaPosts: 1548 |

ok, thanks for all the feedback , might have to go back to a lighter wind-gennie. worked perfectly with the F&P lightweight gennie... Bruce Bushboy |

||||

| Page 1 of 2 |

|||||