|

|

Forum Index : Windmills : F&P 36 pole aluminium stator power output

| Author | Message | ||||

| DaveP68 Senior Member Joined: 25/11/2014 Location: New ZealandPosts: 292 |

Tried a F&P 36 pole aluminium stator today for the first time just to check how it compares to a copper version. Results were 615 W at 588 RPM on my crude test rig. Other reading are 410 VDC and 1.5 Amps into my controlled current load. This is about 7% less output power than the copper stator. Open circuit volts reading is about 1.1 VDC per 1 RPM. Copper stator is around 1.185 VDC per 1 RPM. This implies that there are less turns per pole. The resistance reading phase to phase star is 38 ohms vs 32 ohms for the copper stator. It's possible to get a good output from them but rewiring them becomes a challenge. Solders used for aluminum generally contain zinc with some lead, cadmium, tin, copper, or aluminum. However, any solder that contains tin may cause an electrochemical corrosion problem due to its galvanic potential. There are realities if you do not accept, will lead to frustration because you will be spending time on wrong assumptions and the results cannot follow! The Dunning Kruger Effect :) |

||||

| Thai Newbie Joined: 22/05/2018 Location: United StatesPosts: 30 |

Is the stator used, one with redesign black cap? |

||||

| DaveP68 Senior Member Joined: 25/11/2014 Location: New ZealandPosts: 292 |

Well not exactly the one outlined in this topic is a 36 pole aluminum stator using a 48 magnet black rotor cap. These are used on all top loading washing machine currently in production. The FP640 stator that you have is a 27 pole aluminum stator that uses a 36 magnet black rotor cap. There are realities if you do not accept, will lead to frustration because you will be spending time on wrong assumptions and the results cannot follow! The Dunning Kruger Effect :) |

||||

| Thai Newbie Joined: 22/05/2018 Location: United StatesPosts: 30 |

Oh i see. I can't find any info on the motors I have. Thanks for the info |

||||

| kalidupakid Newbie Joined: 18/10/2018 Location: IrelandPosts: 3 |

Hi Iv just joined after some time just looking and thinking I must have a go at a windmill, for now I want to just play around and see if I can get any decent results, I got a F&P 36 POLE .6MM wire unit, with a black cap 48 pole rotor these are single magnets, from a used washer, in your rewire section there is no mention of this set up. Im after a general speed mill with either 12 volt or 24 volt output, and dont want to have to re solder because I picked the wrong connections. any advice. |

||||

| yahoo2 Guru Joined: 05/04/2011 Location: AustraliaPosts: 1166 |

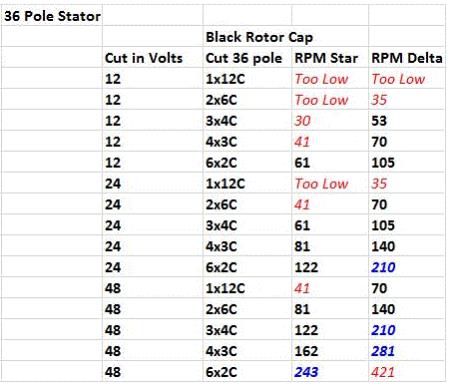

F&P stator rewire  I thought this would be your unit. What is different? is it the wire resistance? We can sort something out, getting a motor charging is not rocket surgery.  the 5 wiring digrams for a 36 pole is just above the charts. You should be able to click on them to get a larger image. the 5 wiring digrams for a 36 pole is just above the charts. You should be able to click on them to get a larger image.if you are not sure about some of the formulas to work out amps and watts from free spinning rpm, stator resistance and battery voltage we can help a little with that. cheers I'm confused, no wait... maybe I'm not... |

||||

| Tatocr Newbie Joined: 16/11/2018 Location: SpainPosts: 4 |

Hi. I'm also doing tests with a 36 LG coils. How different are the F&P and LG engines? In this video you can see the very poor numbers offered by my LG washing machine motor with 36 coils, 0.8mm cable and rotor with 12 ferrite magnets. https://www.youtube.com/watch?v=mLwl9M4BLj0 It is foolish to pretend to make a wind turbine with this amperage. I suppose that changing the magnets by neodymium improves the performance but I do not find information on polarities, sizes etc ... |

||||

| Pete Locke Senior Member Joined: 26/06/2013 Location: New ZealandPosts: 181 |

What were you using for a load for the current check? |

||||

| Tatocr Newbie Joined: 16/11/2018 Location: SpainPosts: 4 |

Hi, Pete. I'm not using anything. I understand that the tests mentioned by DaveP68 are empty, without load. I'm wrong? Here it also says that it is empty  I'm wrong? Sorry but my English is very poor |

||||

| sonny97301 Newbie Joined: 10/08/2019 Location: United StatesPosts: 8 |

anyone who wants a good pma should just BUY ONE. on ebay/amazon. look for permanent magnet alternator, and KNOW the spec's that you want. btw, in a correctly configured pma, there should be JUST THREE coils per phase. not 12 or nine or 25. googletranslate |

||||