|

|

Forum Index : Windmills : F&P 36 pole 40% more power than 42 pole

| Author | Message | ||||

| DaveP68 Senior Member Joined: 25/11/2014 Location: New ZealandPosts: 292 |

Hi All After months of testing, I've got data to prove that a 36 pole copper stator with black rotor cap has a 40% higher (linear) power output compared to a 42 pole over same RPM range. These tests were done with both stators wired uncut Delta mode. Here is a graph and complete set of data tables (RPM, Power, Volts & Current.    The photo above is of a 42 pole stator set up as for the first test run. We ended up using both the 36 and 42 in Delta as voltage on star got over 500 VDC under load and our rectifier + capacitors are only rated up to 500 V. Max RPM reached was 1155 RPM with peak power output of 1290 W on 36 pole with black rotor cap. Only got access to this Lathe last month hence why I've been able to complete far more testing and publish a complete set of data, including the "F&P stator cut in Volts vs RPM tables". Yes the test voltages at high power are high and for practical use the stators would need to be cut into different configurations (i.e. 6x2C or 7x2C). Like I've described in my tables of "F&P stator cut in Volts vs RPM tables". I have seen comments on this site stating the best stators are the 80s and 100s depending how they are used. I would be very interested in seeing how a 42 pole stator can be configured to match this 36 pole stators (with black rotor cap) data or better it. I'm not referring to the modified 7 phase wired to use a black rotor cap as the wiring is quite complex pull off and once done is hard to reconfigure. David There are realities if you do not accept, will lead to frustration because you will be spending time on wrong assumptions and the results cannot follow! The Dunning Kruger Effect :) |

||||

| DaveP68 Senior Member Joined: 25/11/2014 Location: New ZealandPosts: 292 |

An update on this 36 pole vs 42 pole stator testing for those that may be interested. Added a "Capacitor multiplier" as per Gordon's design and got a some good improvements in the low to medium RPM range up to 400 RPM both 36 & 42 pole stators. Yes this is where better performance is needed anyway. But even using a "Capacitor multiplier" on a few different 42 pole stators I couldn't get as much power out as a 36 pole copper with Black Cap. By far the 36 pole copper "Factory Decogged" with a Black rotor produces more power output overall. Let's say you put a "Capacitor multiplier" on a 42 pole and state it will out perform a 36 without the "Capacitor multiplier". That isn't a fare comparison as one just needs to add a "Capacitor multiplier" to the 36 pole and it will just put even more power than 42 pole. The laws of Physics are what are... There are realities if you do not accept, will lead to frustration because you will be spending time on wrong assumptions and the results cannot follow! The Dunning Kruger Effect :) |

||||

Downwind Guru Joined: 09/09/2009 Location: AustraliaPosts: 2333 |

I find your testing interesting but a little useless. For 1) who would want a mill running at over 1100 RPM, we normally run and hide way before that RPM. 2) producing high voltage like 500V is just pure dangerous and stupid for a home grown mill, even more so when many first mill builders have little idea of lethal voltages these stators can produce when not modified. 3) Mechanical testing (like a lathe) it almost useless when compared to real wind driven tests. Im still not sure what you are trying to prove with your tests, as it has all been done before and well posted on this forum.(other than the black rotor) Good to see you reinventing the wheel, but if you dig deep enough into the forums past you will find almost the same results that have all been posted before. Its nice to have a fresh mind working on development, just be careful to what you claim as your developments as there is a long and old history of simular test results. Sometimes it just works |

||||

oztules Guru Joined: 26/07/2007 Location: AustraliaPosts: 1686 |

Dave, thanks for the very useful table you have spent time to produce. It gives me a good idea of how the stator can be used. I have a few here now, and have not had the time to get an idea of their dynamic range. I do appreciate the high rpm, and natural voltage figures, as I would not use these in the mode that folks here do. I would run them natively. The best home use windmill I have ever had the pleasure of being associated with does not cut in until 200vac, and thats the African Wind Power, designed by Hugh Piggot. It is high voltage, and generally produces 24kwh per day average. It has survived a decade of the worst winds that the roaring forties have produced, in a marine environment, with forcing voltages well in excess of 500vac. I don't believe that all neophytes are incompetent idiots. I also commend the bench test. For those still interested in carving their own blades to get the best performance, we need to have the power curves so that a decent TSR and diameter can be arrived at. It is not possible without this information to make an informed decision. For those using the chinese blades, then less reason to bother perhaps. The high rpm figures are very practical if you use the Chris Olsen style mill head, but more importantly, they also give us an indication of the synchronous impedance and by looking at the graph we can see that the normal limitation faced by F&P builders which is imposed by not letting the voltage rise, is eliminated, as the inductive reactance is not prominent in these graphs. If we were to use the Olsen head and a normal GTI, it would be a perfect combination to drive back into a LF inverter, and well over 1kw would be easliy achievable for a single stator.... interesting idea. The leakage in these stators appears to be quite high, and this normally makes braking difficult, but if we can keep the line impedance high to match the stator, normal braking should be very possible, as the leakage impedance will not current limit and let the mill over speed. So thanks for your work in this area, I may still get an F&P up in the air.... and it will be high voltage.... probably grid tied to my inverter for battery charging if the house does not use enough of the power directly. The HV will also allow the mill to be hundreds of yards away from the house. ............oztules Village idiot...or... just another hack out of his depth |

||||

| flc1 Senior Member Joined: 20/11/2011 Location: New ZealandPosts: 242 |

Well said Oztules, the mppt inverters that I have said are availble online can allso work in voltags from 30-500 v dc and ac, well suited to a fnp.And the fnp appears to run very quiet when useing higher voltages.Downwind,My geared up mill runs up to a 1000 rpm on one of the stators,so its very useful data, Fred |

||||

| DaveP68 Senior Member Joined: 25/11/2014 Location: New ZealandPosts: 292 |

So you find my testing interesting but a little useless, what a contradiction of terms... If you carefully read what is in the post I state "Yes the test voltages at high power are high and for practical use the stators would need to be cut into different configurations (i.e. 6x2C or 7x2C). Like I've described in my tables of "F&P stator cut in Volts vs RPM tables". So that has been covered off too. I haven't found ANY comprehensive test results for 42 or 36 pole ststors on this site, well not in the way I've formatted it anyway. So you don't want an improvement of 40% output for the "exact same" RPM? That is exactly what the Black Rotor cap does when configured correctly, which is the WHOLE point of me publishing this data. As for reinventing the wheel you must live in a world that all wheel are created equal!! That isn't the case in my world. Lets take the wheel used on a train it doesn't work on our roads at all (it's a wheel)... Take a wheel on a Boeing 777 and go and try fit that to a large Truck, won't work very well when swapped over. Aircraft tyres are designed for high rotation speeds of 300 kph+ for take off/landing, a large truck is lucky to do a 3rd of that speed under normal operating conditions. Having both worked in Rail and Aviation I understand these very important differences between "wheels". So a 36 pole copper stator with black rotor cap will out perform any 42 pole stator... One wheel can be better than another wheel  Thanks for the compliment re fresh mind working on this stuff. I have NEVER stated the words "developments or developed" relating directly to Stators. Did say I was developing a form of Buck MPPT converter and FET switching unit which haven't been completed yet. I'm also on record endorsing ALL the great work that has been done on this site to date by many others including you. There are realities if you do not accept, will lead to frustration because you will be spending time on wrong assumptions and the results cannot follow! The Dunning Kruger Effect :) |

||||

oztules Guru Joined: 26/07/2007 Location: AustraliaPosts: 1686 |

Fred, It would be very interesting to see a native stator driving say an aerosharp 3kw GTI. It may need a clamp over 500v, and would need a brake circuit as if the battery is full, and the house does not need much power, then the voltage will rise and the GTI will drop off, we then simply brake it with a matched load. It would be very efficient using this instead of the normal battery charging regime, which is terrible in the form of efficiency. We should be able to get around the crest factor distortion, as the pfc front end in the mppt should allow using the whole wave, not just the crests. So this may be the only real way of using the F&P to it's full potential, and with GTIs so cheap, and the highly efficient synchronous rectification the LF inverters allow, you could squeeze most of the figures Dave published .... into the batteries, which would not be possible any other way as I see it. Cheap high power low frequency inverters, and cheap almost disposable GTI's make things possible that we never dreamed were possible only a short time ago... I mean who would have though to use a native HV F&P stator, and expect to spank any figures, any other traditional system used. It finally allows full potential of the F&P stator, at any battery voltage ... without any modification at all. I guess Dave has reinvented the wheel  ..........oztules Village idiot...or... just another hack out of his depth |

||||

| flc1 Senior Member Joined: 20/11/2011 Location: New ZealandPosts: 242 |

thats the one Oztules, Daves tables need to be added to the fnp contents page, to save them from dissapearing in the forums again like the older testing results. I would never have broke the 1kw mark with my turbine if I had not used a higher voltage mppt inverter and then added( daves idea) black rotor caps. |

||||

| DaveP68 Senior Member Joined: 25/11/2014 Location: New ZealandPosts: 292 |

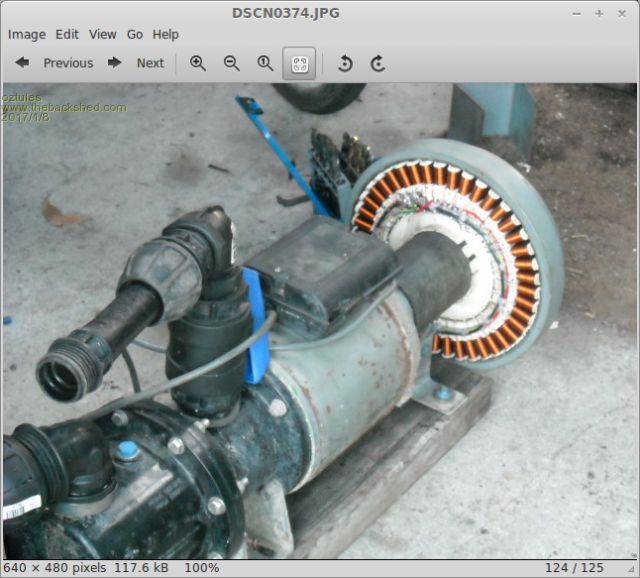

Hi Oztules Thanks very much for endorsing the hard work I've done with testing F&P stators mostly for the purpose of publishing data tables/graphs. Thanks also Fred for acknowledging that it was my data about the 36 pole copper stators with black rotor caps that allowed you pass the "Mythical" 1 kW limit  You so far are one the few that has seen the "untapped" potential of these F&P stators, especially the 36 pole copper "Factory Decogged" with a Black rotor cap. To the non believers, how you could over look the simple fact that they give out 40% more power output for the same RPM than a 42 pole stator... Thanks also for putting me onto the Aerosharp 3kw GTI, just checked out it's specifications on a Google search. Here is a post on and responses re a 50 to 500V MPPT the product is "Tristan MPPT 600V" (can use for PV up to 600V & wind + hydro to 500 V) 500V MPPT wind charge controller do exist As for controlling the voltage in a for breaking purposes above say 500V as you have pointed out, is easily done with a dynamic brake circuit. Check out the circuit board in light blue plastic casing in the photo below. I'm only using one small part of the overall circuitry of a F&P motor controller board. It just so happens to have a dynamic brake circuit that normally cuts in at 400 VDC. It's can easily be modified with higher rated components to operate well in excess of 1 KW into a "LARGE" resistor at 500 VDC cut in or what ever voltage around that. So in summery like you say, all the hardware is out there "at a cost of course" to home build a will turbine using F&P stators and get the full output power potential. There are realities if you do not accept, will lead to frustration because you will be spending time on wrong assumptions and the results cannot follow! The Dunning Kruger Effect :) |

||||

oztules Guru Joined: 26/07/2007 Location: AustraliaPosts: 1686 |

Yes they are quite versatile if you give them a chance.. Eg.. here I used it to drive 1k5 hp mono pump...used the original motor as a bearing block  It runs on solar panels the same as a normal solar pump would.  So am familiar with driving them ( I used a moc33033 chip, not the F@P, as it was for a 48v unit.) I think breaking would be very simple, and not require the "breaking" circuit, as if we match the synchronous impedance, we will probably get as good as we need. It will not run away like a short circuit would do, but act as a dynamic brake... slow but not stopped I suspect. The inductive reactance is what would normally do that runaway bit with a dead short. People would have noticed it is probably best not to direct short it, but to put a big resistor across it instead, and that slows it down until the TSR drops off, and stops it. It can also be seen as a eddy current reaction, so is inversely proportional to the rpm. Well done. ............oztules Village idiot...or... just another hack out of his depth |

||||

| DaveP68 Senior Member Joined: 25/11/2014 Location: New ZealandPosts: 292 |

Hi, great to see the F&P in yet another application other than washing clothes and generating power.  The way the dynamic brake circuit works, is when you get to the trip voltage (brake application) of say 500 volts it switches in a low resistance load (28 ohms on an F&P module). At this point the voltage will suddenly drop at a steep gradient to cut off threshold voltage of say 450 V and it lets go. This is all achieved via simple comparator circuit with a small amount of hysteresis. The switching element being a high power, high speed IGBT. This operates as an independent circuit, but in parallel to a high voltage MPPT Inverter as you described earlier in this post. That way the dynamic braking is only taking away any excess energy that is over and above to what the Inverter can convert to charge batteries or feed back into the grid. The cheap Chinese (non certified though) GTI wind turbine inverters have them built in. The resistors seem to be a bit under rated if you loose power in high wind conditions. This just an observation though, as they would have to take all the load if nothing is going back into the grid. There are realities if you do not accept, will lead to frustration because you will be spending time on wrong assumptions and the results cannot follow! The Dunning Kruger Effect :) |

||||

| gpalterpower Senior Member Joined: 19/07/2009 Location: AustraliaPosts: 175 |

Hi Dave, These are interesting stats. It really is amazing how much more power the black rotor with 36 pole stator creates. Bout a year ago I picked up a black rotor and stator. I didnt realise till I got home and inspected it a bit more closley that I ended up with the Ally wound coils. Not to be deterred, I reconfigured it to a 3x4c and fitted it to the mill. There was an immediate increase in power and kicked in at a lower rpm. So im wondering if there is a huge/marginal difference in the output of the copper compared to Ally windings. Im still on the lookout for another, but will be searching for the copper stator if the output is higher. Any graphs on these? Marcus if it aint broke dont fix it!! |

||||

| DaveP68 Senior Member Joined: 25/11/2014 Location: New ZealandPosts: 292 |

Hi Marcus Yes the Ally stators will work about a 20-30% drop in output power at a guess. You need to look for the machines that have the cream coloured rotor caps to recover a 36 pole copper stator. Here are the Australian product codes that have the 36 pole copper stators; 93125-A, 93127-A, 93194-A, 93195-A, 93196-A, 93198-A, 93200-A, 93201-A, 93202-A, 93203-A, 93220-A, 93221-A If a Kiwi shipped their machine over from NZ in the last 10 years the product codes all start with 92xxx-A, so pick and choose what market they are made for. Hope this is of use to you, as once you get a copper stator you can start getting the results that Fred and I are getting. I take it you spotted my latest post of 700 W @ 520 RPM from a 36 pole copper stator? They just blow away any 42 pole stators output potential. There are a few die hard non believers on this site who try to challenge my data tables/graphs etc, but produce not a scrap of raw data of their own to back up their claims... I may not be a Guru on this site, but when it comes to F&P stators have a very close relationship with the team at Fisher & Paykel who developed this amazing PMA. So you could say I can do insider trading, but of a legal kind. Cheers David There are realities if you do not accept, will lead to frustration because you will be spending time on wrong assumptions and the results cannot follow! The Dunning Kruger Effect :) |

||||

| gpalterpower Senior Member Joined: 19/07/2009 Location: AustraliaPosts: 175 |

Hi Dave, Yep. I saw the output from your stator. Impressive  My mill is a dual setup, so if I can get another black rotor and 2 stators fitted, then that would make it a serious contender. Seems the copper winding are still a lot better....and better to solder as well. Ally windings to solder, is finicky at the best! We get a fair bit of wind at night here, so with output like that would nearly see us thru till morning when the solar takes over. My mill is a dual setup, so if I can get another black rotor and 2 stators fitted, then that would make it a serious contender. Seems the copper winding are still a lot better....and better to solder as well. Ally windings to solder, is finicky at the best! We get a fair bit of wind at night here, so with output like that would nearly see us thru till morning when the solar takes over.Ive been asking the guys at whitegoods repair shops around the area if they have any spares. I found one at the Gold Coast, but it still has the Ally windings so im a bit reluctant to pick it up. However, it has the black rotor so I might have to bite the bullet and purchase both just for sake of the rotor. Maybe a trip to the tip might be in order. Ive seen plenty of scrapped whitegoods there.  Marcus if it aint broke dont fix it!! |

||||

| DaveP68 Senior Member Joined: 25/11/2014 Location: New ZealandPosts: 292 |

Hi Marcus As per the Fisher & Paykel Washing Machine product code list provided, I'm sure you will easily pick up a couple of 36 pole copper stators sooner or later. If you can let me know your current wind turbine setup, i.e. blade diameter, system operating voltage and what your current max RPM/output power level is? I will then be able to give you advice on how to get the most out of 2x 36 pole copper stators with black rotor caps. Like I stated in another post, 700 W output per 36 pole copper stator is possible at about 520 RPM if configure correctly. Cheers David There are realities if you do not accept, will lead to frustration because you will be spending time on wrong assumptions and the results cannot follow! The Dunning Kruger Effect :) |

||||

| gpalterpower Senior Member Joined: 19/07/2009 Location: AustraliaPosts: 175 |

Hey Dave, My blade diameter is 3.15M using GEO 222 pvc blades set at 13 degrees, 24v system. Max power ive seen is bout 550w , and that was in a gale. RPM im not sure of, but its been scary to watch at times! I just close the back door and go inside hoping its still standing the next morn. And thankfully it always is.  Marcus if it aint broke dont fix it!! |

||||

| DaveP68 Senior Member Joined: 25/11/2014 Location: New ZealandPosts: 292 |

Hi Marcus As you are running a 24 VDC system, using a 36 pole does make it a bit trickier but still possible 2 extract over 1000 W peak. That's double the output power of your current setup. If Fred (flc1) can get a peak of 1.1 kW output from a 2.4 m diameter Dual F&P wind turbine, you should be able to do as well with a 3.15 m blade diameter. Fred is using gearing and a MPPT GTI inverter, so there are some other differences in each respective setup. You will also need to build 2 different "Capacitor Multipliers" with component values TBA. The first 36 pole copper stator will be set up "staggered" cut as 1x6C and 3x2C both wired in Delta. The first "Capacitor Multiplier" will be added to the 3x2C output. The 1x6C output just goes direct into a rectifier. The second 36 pole copper stator will be set up is 12x1C wired Delta with it's output into the second "Capacitor Multiplier". The cut in points for the 3 stator outputs will be 70 RPM 1x6C Delta, 105 RPM 3x2C Delta and 210 RPM 12x1C Delta. If the 70 RPM cut seems a bit low you could try changing to a 2x3C Star cut on first stator instead of 1x6C Delta and 81 RPM will be the cut in with a bit more current at start up. Hope you can make use of this setup info to get a decent increase in output power. Cheers David There are realities if you do not accept, will lead to frustration because you will be spending time on wrong assumptions and the results cannot follow! The Dunning Kruger Effect :) |

||||

| gpalterpower Senior Member Joined: 19/07/2009 Location: AustraliaPosts: 175 |

Thanks Dave, That sounds good. Ill be on the hunt for some more stators. If I could get 1k output that would be awesome. Even 750 or even 500w at a lower rpm would be better that 500w in a gale that im getting now! We're going away for a few weeks so Ill get back into it on our return. Marcus if it aint broke dont fix it!! |

||||

| DaveP68 Senior Member Joined: 25/11/2014 Location: New ZealandPosts: 292 |

Hi Marcus Your welcome and only too happy to give away this advice at no cost, as get all my F&P hardware for free anyway. That's what this site is all about. . Will update you latter on the Capacitor Multiplier parts list and how best to construct them if you're not sure. Look forward to seeing some results once you've completed the rebuild. If you get over 1 kW you will certainly have an ultimate F&P dual that feeds into batteries. Have a good time were every you are heading. Regards David There are realities if you do not accept, will lead to frustration because you will be spending time on wrong assumptions and the results cannot follow! The Dunning Kruger Effect :) |

||||

| flc1 Senior Member Joined: 20/11/2011 Location: New ZealandPosts: 242 |

Good stuff Dave, yea forget about the 42 poles on windturbines, they just don't cut it. Marcus look for the rotors with the 5 raised knobs around the edge of the rotor,thats a arrow head on a 36 pole, and should have a copper stator.You should easily get 1kw with the setup Dave talks about. Fred |

||||