|

|

Forum Index : Windmills : Slowly turning but loaded

| Author | Message | ||||

| Goodz Newbie Joined: 01/09/2014 Location: New ZealandPosts: 9 |

Hi All Thanks for info from Gizmo and others. Have addressed the power from turbine thing.change to bigger blades and different wiring. Blades dia now 2.4 metre and have fitted the 1x6c poles with new type rotor Volts across DC leads out of rectifiers is when Free running at 400rpm =186V Now have connected batteries and volts read 25.61?(battery)and Amps up to 1 amp but mainly around 0.3to0.5. When breaker switch off turbine increases volts/revs dramatically OK. But when switch on, turbine really seems to be working hard just to keep turning in good breeze to maintain the 25+ volts and amps IS This Normal and desired outcome. for battery charging. Your help most appreciated as seem to be spinning wheels here regards Goodz |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

What blades do you have on it? Can you post a picture? The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi Goodz By the voltages you are getting open circuit it is still in high voltage mode in the wingdings, i think you need to reconnect the poles as shown in the conversion wingdings to get it to charge 24 volts successfully, go in from the front page of the forum to the winding conversion and check what the wingdings need to be for 24 volt charge. All the best Bob Link to page:: http://www.thebackshed.com/windmill/FPRewire.asp Foolin Around |

||||

| gww1 Regular Member Joined: 14/06/2013 Location: United StatesPosts: 63 |

You have eight foot blades, you need to get the turbine to hit the 24 to 25 volt range at about 200 rpm. That will allow the blades to keep thier speed before a large load is placed on them. I might be wrong with the fisher pykel but on a hugh piggot turbine this is what gives you good charging range through the charging band ie wind speed changes. Just my oppinion. gww |

||||

| Goodz Newbie Joined: 01/09/2014 Location: New ZealandPosts: 9 |

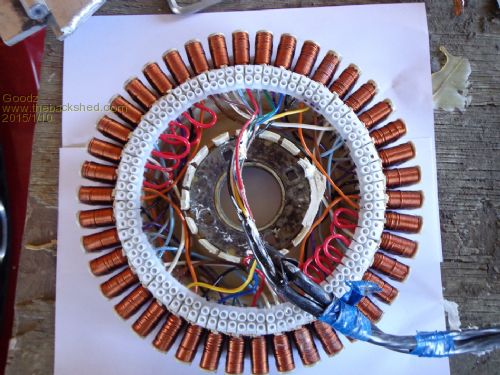

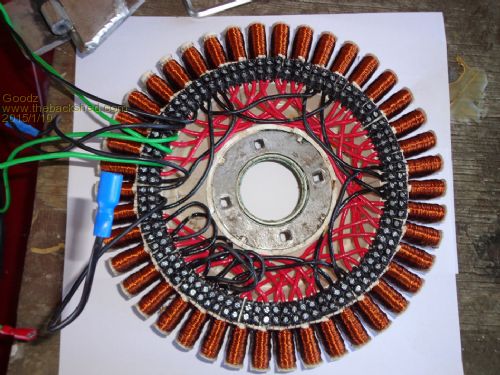

Hi Gizmo find pics here of my rewired poles and the blades running the unit now cheers Goodz

Hope you can be of some help. Have read that maybe the 60s are not the best and should I swap wiring to the 80s. Easy with the connectors in place !! regards Goodz |

||||

| Goodz Newbie Joined: 01/09/2014 Location: New ZealandPosts: 9 |

Hi all In pics the top photo shows the 0.8 dia wire,set up as 2X3C 7 phase The bottom shows the 0.6 dia wire set up as 1X6C 7 phase regards Goodz |

||||

| Tinker Guru Joined: 07/11/2007 Location: AustraliaPosts: 1904 |

Hi, that is certainly the most unusual way to connect to the individual stator coils that I have seen. I would think that there is a very good chance for one or more of the 80+ screw terminals making a poor contact to the enameled copper wire. Why not solder the connections? With soldering its easier to see if the enamel insulation was not properly removed as the solder joint will look bad - at least to my trained eye. Klaus |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

I would put the 2X3C 7 phase into service and see how that goes. You need to get the RPM up a bit to make any real power. Those types of blades can be a bit of a problem, not the best option, but enough to get your started. Check the angles neat the tips, easy to get a negative angle of attack and dramatically reduce the power. Some GOE222's or carved timber blades will perform much better, and handle strong winds. Tinker I've see a few forum members use the screw terminals before, its good for experimenting. Long term though I agree, solder connections are better. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| gww1 Regular Member Joined: 14/06/2013 Location: United StatesPosts: 63 |

I agree with gizmo on the blades also. I played with blades just like that before I found that even simple cheap pine strait angle blades were as easy to make and worked better. I like the twisted blades even better and it doesn't kill them if you make a few flaws while doing them. I have no luck with pvc and I find them harder to mount also. gww |

||||

| Goodz Newbie Joined: 01/09/2014 Location: New ZealandPosts: 9 |

Many thanks for thoughts will work my way thru them and see what ensues. regards Goodz |

||||

fillm Guru Joined: 10/02/2007 Location: AustraliaPosts: 730 |

Hi Barry, Hey very nice work and yes it is a great way to learn. As I have advised off forum, and as Glenn has said you need to get the RPMs matched with the blades , especially the PVC pipe. From the pictures you still have way to much material (curve) out at the tip. Ideally you need to remove enough so the blade tip looks like an airfiol and a lot flatter, but this is a double edge sword with Pipe blades as they then become weak . From about 1/2 way take material off the back of the blade until the tip is about +2deg or even less AOA, if you can. For your 24V with the 80S try 2x7C, in star and if it loads to much and stalls then go delta. PhillM ...Oz Wind Engineering..Wind Turbine Kits 500W - 5000W ~ F&P Dual Kits ~ GOE222Blades- Voltage Control Parts ------- Tower kits |

||||