|

|

Forum Index : Windmills : Modded OEM windmill

| Author | Message | ||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

Thought I would share my current windmill. Its a pre-production OEM type that I've had for a while, with a few recent modifications made using help from Phill. Phill has spent a lot of time sorting out the problems with these mills and the end result is pretty good. The mods include changes to tail furling angles, etc, and I've added a pull to furl cable. I'm still running the standard turbine diameter. Mine is set to furl early, and I see about 500 watts max. I want to keep it that way for now, the winds out here can get nasty. I've also added a LED garden light to the nacelle, just for fun.

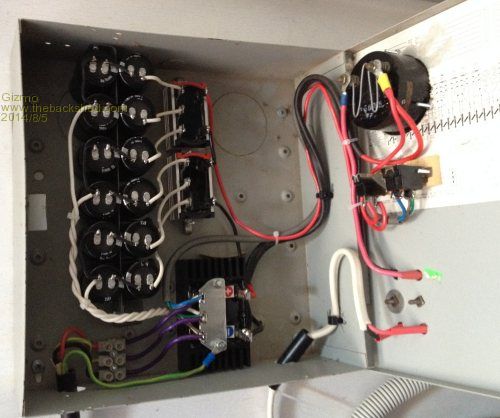

To run the mill at 48 volt I'm using a cap doubler with parts supplied by Phill. Mounted in a old alarm box, includes a amp meter, couple of old house fuses, and a switch to bypass the cap doubler, and another switch to short the windmill if needed. The old fuses do act as fuses, but also a quick way to isolate the windmill from my 48 volt battery bank. I get a lot of wild electric storms, and a pulled fuse provides over an inch of isolation, on both neg and positive. The cap doubler is working most of the time, and can supply around 5 amps at the higher speeds. Once the winds pick up the windmill output voltage is high enough to drive a larger 3 phase rectifier directly. The cap doubler means I'm making use of winds below the usual cut in speed of this alternator/batter combination.

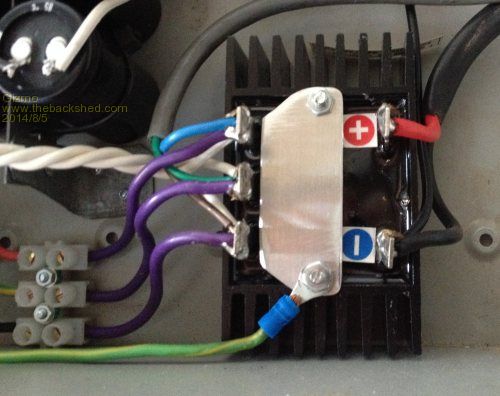

The last photo shows a spark gap plate mounted to the main rectifier. It gives a 1mm gap between the 3 phases from the windmill and ground, again more lightning protecting and easy to construct. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

Madness Guru Joined: 08/10/2011 Location: AustraliaPosts: 2498 |

Glenn do you have a wiring diagram of the cap doubler or a link to one. When I used to have a Dunlite mill I had a device that would make some power at lower RPM, but that was a DC generator. Some days it would run all day in a light breeze producing a few amps. If I did not have it it would have made nothing at those times. Thanks Gary There are only 10 types of people in the world: those who understand binary, and those who don't. |

||||

Downwind Guru Joined: 09/09/2009 Location: AustraliaPosts: 2333 |

Dont anyone ever check the information listed on the front page of the forum. http://www.thebackshed.com/windmill/articles/GordonsCapMod.a sp Sometimes it just works |

||||

Madness Guru Joined: 08/10/2011 Location: AustraliaPosts: 2498 |

sorry I asked. There are only 10 types of people in the world: those who understand binary, and those who don't. |

||||

| jkis Newbie Joined: 31/07/2014 Location: AustraliaPosts: 16 |

don't be sorry it will benefit a lot of people that read this post. cheers stuart |

||||

| jkis Newbie Joined: 31/07/2014 Location: AustraliaPosts: 16 |

Gizmo, the wiring looks very neat, i wonder if the solar light would help keep fox,s away with it changing position ect, would you be able to use circuit breakers in place of the old type fuses or are they better as a slow blow type. cheers stuart |

||||

fillm Guru Joined: 10/02/2007 Location: AustraliaPosts: 730 |

Hi Glenn, Thanks for the mention , yes I have done a lot of work with these mills in sorting them out and only have a few left if anyone is interested, I have worked out solutions for all voltages 12/24 and 48 furling and the Manual furl all though you do a little different but along the same path that I suggested . Nice job on the Cap Doubler

About a month or so ago a customer contacted me with a later model down wind 1000W model that were flogged of here by an unscrupulous import company who sold them , really they were just the 500w internals and marketed as 1000w with bigger blades and Down wind .....yuck....... the only reason they went down wind was they could fit more in a contaier. They can easily output 1000W+ but can be short lived so I like to keep them with 2.750M Max Dia with very light furling and Manual furl , even with the blades pulled into furl in strong wind they can reach 500w easy. I have seen 1600W in a big blow but the side effect was fatal. Anyway I completely overhauled & refurbished it to a up wind and it came out very nice, changed wiring config to 12V and he is Happy as a pig $^it. Personally I do not like 12V but there are a lot of benefits with easy asccess to accessories - Heres a couple of Pics

PhillM ...Oz Wind Engineering..Wind Turbine Kits 500W - 5000W ~ F&P Dual Kits ~ GOE222Blades- Voltage Control Parts ------- Tower kits |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

The fuses are really there to act as a isolation switch. Pulling the fuses gives a 1 inch gap, which is way way more than a regular switch or circuit breaker. Another option would be a big knife switch, but I have heaps of those old fuses. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| domwild Guru Joined: 16/12/2005 Location: AustraliaPosts: 873 |

Glenn, Very nice job with very neat wiring! Am green with envy! Taxation as a means of achieving prosperity is like a man standing inside a bucket trying to lift himself up. Winston Churchill |

||||