|

|

Forum Index : Windmills : rectifiers

| Author | Message | ||||

| slaird Newbie Joined: 01/08/2013 Location: AustraliaPosts: 5 |

Hi All, Just chasing some advice thanks. is it possible to put two bridge rectifiers in series in order to double the DC output.The reason I ask is that i have built a large Savonius wind turbine with two F&P's mounted top and bottom direct to the shaft. in good winds it spin's around 100 to 130 RPM's and each motor is putting out about 30 volts. my problem is that the system I have is a 48 volt system. What options do I have other than gearing up using belts or chains? I wanted to avoid this. Thanks Steve |

||||

Madness Guru Joined: 08/10/2011 Location: AustraliaPosts: 2498 |

Your not going to get much power at those RPM's. You can use capacitors increase the output but it will still be disappointing. It is not what you want but gearing it up is the best solution. There are only 10 types of people in the world: those who understand binary, and those who don't. |

||||

Downwind Guru Joined: 09/09/2009 Location: AustraliaPosts: 2333 |

Im not sure why you would want to use two rectifiers in series as they convert AC to DC and not not some magic device that makes power, all you will get is double the diode loss .... so less voltage. Perhaps a different rewire of the stators might help increase voltage output. Its the problem with a VAWT that RPM is often low and you produce next to nothing in power (there is a good reason why we build a HAWT its called RPM) Another option might be to build a stepup transformer for the 3 phase with a 2:1 ratio, but again you will introduce high losses. Perhaps a cap doubler is your best option, as losses are low and its been proven to work well with windmills, as it should reduce your cutin RPM by about half, although the power output will be somewhat less too, but something generated most of the time is far better than a lot of nothing all the time. Pete. Sometimes it just works |

||||

fillm Guru Joined: 10/02/2007 Location: AustraliaPosts: 730 |

Hi Steve, It is possible to series the DC on the two rectifiers from each F&P and double the voltage output but it will 1/2 your current. This doesnt matter because you need the high volts for 48V and you didn't have any before. I did this on my earlier Dual stators but with hawts there are many more options to play with. The best advice I can give you is check the stators you are using, you will be better of with 60 series unmodified stators and you will get cutt-in around 50-60 rpm on both stators. PhillM ...Oz Wind Engineering..Wind Turbine Kits 500W - 5000W ~ F&P Dual Kits ~ GOE222Blades- Voltage Control Parts ------- Tower kits |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

Some info on cap doublers... http://en.wikipedia.org/wiki/Voltage_doubler A doubler will give a higher voltage than you already have, but at less current, and less overall watts. How big is the savonius Steve? Would give us an idea of what you could expect from it. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| slaird Newbie Joined: 01/08/2013 Location: AustraliaPosts: 5 |

Hi Phill, Both stators are 60 series unmodified. most of the information on this site talks about rewiring the stator for less voltage and greater current (for high RPM Systems). is it possible to rewire in the other direction say 1x21C on the 42 pole stator (two Phases)(I hope that is right) (as Pete suggested possible rewiring). Hi Pete, you suggested a Cap Doubler has worked in the past. how is this wired in, what size and are they available of the shelf at PCB Electronics? Thanks all for replying, I do appreciate it! Steve. |

||||

mac46 Guru Joined: 07/02/2008 Location: United StatesPosts: 412 |

I have a vertical mill. I think that you may be disappointed in trying to gear it up in an attempt to make power...all the belts and gears rob the power leaveing you in about the same power range. If you do gear it up try to stay at 2 to 1 ratio or less. What wing frofile are you useing? Maybe a different wing will help...seems that the lighter the better, or that is... the bigger and lighter the better. Keep us posted on what is happening. Mac46 I'm just a farmer |

||||

| slaird Newbie Joined: 01/08/2013 Location: AustraliaPosts: 5 |

Hi Mac, what is the design of your unit? My mill is constructed from 3 x 205ltr drums cut in half and mounted conversely on a single shaft. it seems to produce good torque at low winds. I am waiting for a reply from others however it seams I may have to use a gearbox to fix the problems. thanks, Steve. |

||||

fillm Guru Joined: 10/02/2007 Location: AustraliaPosts: 730 |

Steve, I am starting to think that your problems are more from expecting too much in light winds , you stated you have seen it do 130rpm was that unloaded or loaded and in what wind , when most ask questions here it seems to take a while to get the whole picture and story. With 2 unmodified 60 series stators cutting in at the same time I think would stall your mill. Have you tried with just 1 stator and being able to switch it on and of to unload and load the mill to see if the mill can deliver the power . Going down the road of gearing up is not worth the effort because of losses and it can be done electrically first , but I think your problems lie elsewhere . PhillM ...Oz Wind Engineering..Wind Turbine Kits 500W - 5000W ~ F&P Dual Kits ~ GOE222Blades- Voltage Control Parts ------- Tower kits |

||||

Downwind Guru Joined: 09/09/2009 Location: AustraliaPosts: 2333 |

Steve, I think you are flogging a dead horse to some degree, and will struggle to produce any real power from your design, simply the mass of the Vawt will work against you to produce enough RPM and not throw the whole show to bit. As Phill said drop one stator off to start with and see what you get with a single stator. With the cap doubler, no they are not an off the shelf product and an item you would need to construct, although its a bit of a black art to get the cap size correct to not over load the mill or be too small that it dont give enough power out. Another method would be to use a step up DC to DC voltage converter, which can be purchased from China, a few here have played with them with some results, i have not. Where are you located, as i do have a couple of cap doublers lying around here, but they might not suit your mill. Pete. Sometimes it just works |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

Say you have a 15kmh wind, then you can expect about 120 to 150 watts shaft power. Running a F&P at say 80% efficiency, aim for around 100 watts electrical power, give or take a dozen watts or so. 15kmh wind is more than the average wind speed for most places, and 100 watts isn't much, but its better than no watts, and if you've already built the wind mill, then may as well use it. But remember there are easier ways to make more watts. You could use both stators, with their own rectifiers, and then the DC outputs connected in series to give double the output voltage. Ideally you should time the stators so the sine wave peaks are aligned for the best peak voltage, but as we are dealing with 3 phase here, don't worry about this for testing purposes, it just means you may gain a few volts later if you took the time to set it up. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

fillm Guru Joined: 10/02/2007 Location: AustraliaPosts: 730 |

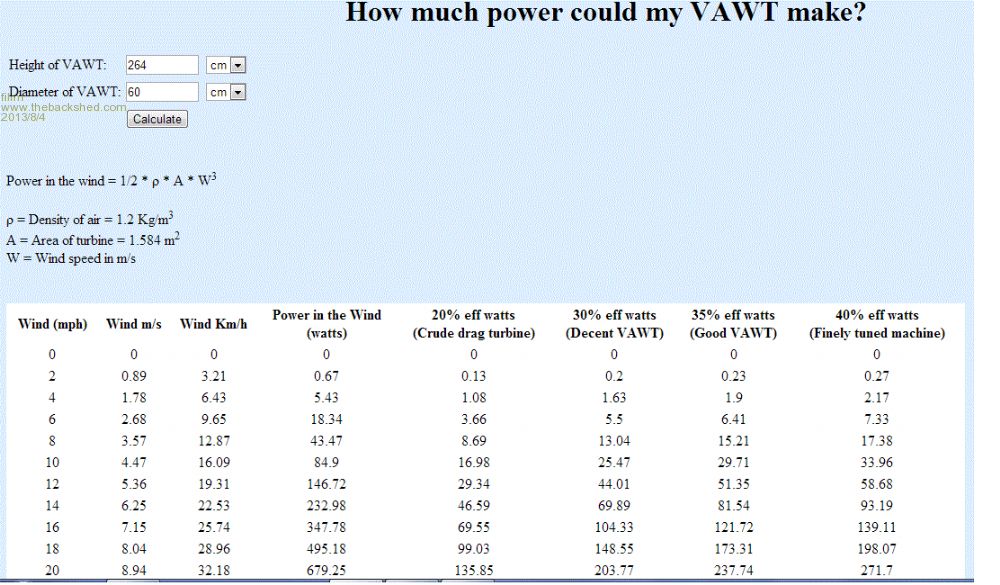

I think a few quick calculations might put your problems into a different light. You say you have 3 x 200lt / 44gal drums cut in half and mounted on top of each other, I am not sure if you have a overlap but I will take it that you don't and it gives more swept area . A 200l measures 880mm H x 610mm , that then would give you a swept area of 2640mm x 600mm which comes to 1.6sq/m, this is all worked out using the calculator on USVAWT HERE . This shows what power is actually available in the wind VS a 20% crude VAWT .

So with turbine power, less bearing seal loss , less cogging loss I think starts to say that gearing or trying to load the turbine any more is the wrong way to go . Rather than going with increasing the size of the swept area until it can drive 1 F&P you can look at reducing the load as the 60S cuts in by using Caps in the reverse way to the doubler and that is to use caps to AC couple to the Rectifier and by adjusting the capacitance will determine the loading. PhillM ...Oz Wind Engineering..Wind Turbine Kits 500W - 5000W ~ F&P Dual Kits ~ GOE222Blades- Voltage Control Parts ------- Tower kits |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

You need to double the radius. My 44 measures 590mm diameter, so cut up and built into a savonius with no overlap, you get a diameter of about 1180mm. A savonius would be regarded as a decent vawt, especially if its got overlap or a modified savonius. A crude VAWT is like a wind anemometer or something made from wheel burrows. But still, only good for about 50 watts shaft power. The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

fillm Guru Joined: 10/02/2007 Location: AustraliaPosts: 730 |

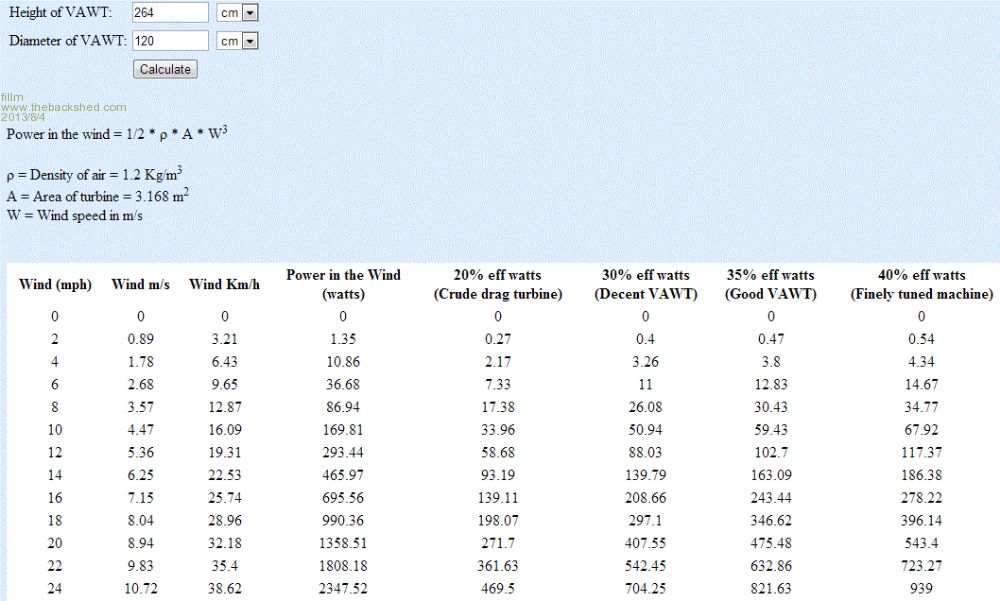

Yea,OK, I Realized I did Radius but in reality it doesn't make much of a difference, I would think of a 44/200L cut in half as a large anemometer and fairly crude, and more the Lenz as getting more to the decent. Anyway more so I was trying to highlight that advice is to easily given, and to have an idea on what power is available to work with first , but also know that having good information to start with helps. Having a overloaded/stalled mill means NO POWER is produced in that state. If Anything it would better to run slightly under-loaded with a mill like this that is virtually self governed, so that would mean sizing the power input to suit the chosen alternator or building the alt to suit, but as I have said previously there are other methods but it just takes getting the grey matter around. Here's the updated power output table from USVAWT which I still think is leaning to the Generous Side

PhillM ...Oz Wind Engineering..Wind Turbine Kits 500W - 5000W ~ F&P Dual Kits ~ GOE222Blades- Voltage Control Parts ------- Tower kits |

||||

| slaird Newbie Joined: 01/08/2013 Location: AustraliaPosts: 5 |

Thanks All, I am Located north of Bendigo on a broad acre property and the Mill is elevated on a slight rise and clear to 100m of any vegetation. It is well balanced and very difficult to stop once spinning however I have not had it under load as yet. The drums have some overlap and the average wind speed is approximately 5m/s. I will remove one F&P, leave the other as direct drive and try to double the current on the AC or DC Side. More information on this would be helpful, even diagrams on how to wire the cap into the circuit. The alternative was DC step-up transformer. - I started looking for DC step-up transformers however hard to find in that voltage range(any links to a website that sells these units would also be great. Phill, your table was very helpful and I do realise now that I should of constructed a horizontal unit instead, however it is in place and some power is better than none. I sort of asked this question before and are still confused regarding it. From the 42 coil F&P can I just have 2 phases of 21 coils each? instead of 14. Thanks again, Steve. |

||||

| Pete Locke Senior Member Joined: 26/06/2013 Location: New ZealandPosts: 181 |

Sorry, but would it not make sense that if you are trying to drive two stators with limited wind (Doing water wheels at the moment so wind for mills hasn't been researched) to just build another windmill and attach the second stator to that? It's easy enough to parallel the two together at the output end. The sizes you are stating doesn't seem to take up a lot of real estate so knock up another one. Shoot me if I'm wrong, but that's what I would look at. Cheers Pete'. |

||||

Downwind Guru Joined: 09/09/2009 Location: AustraliaPosts: 2333 |

Something like this could be suitable, but i have not used or tested one, although i think others here have. Pete. http://www.ebay.com.au/itm/1pcs-Boost-DC-DC-Converter-Power- Supply-Step-up-Module-10-60V-to-12-80V-600W-mah-/30089631066 8?pt=LH_DefaultDomain_0&hash=item460ed1558c#ht_2773wt_1161 Sometimes it just works |

||||

| Tinker Guru Joined: 07/11/2007 Location: AustraliaPosts: 1904 |

The above mentioned DC-DC converter (I use a smaller capacity unit) is the only means I ever got some charging power out of my 5 blade Lenz VAWT. This thing simply does not spin fast enough to make cutin voltage to my 24V battery bank either from direct output or by the capacitor doubling method. I have all three permanently connected via separate Amp meters so I can see where the power comes from on the rare occasions my VAWT ornament experiences a strong enough wind gust. Disconnecting the output from the generator makes it spin merrily even in light winds but that slows to a crawl once the load is applied via the 1:6 planetary gears. Klaus |

||||