|

|

Forum Index : Windmills : 90VDC motor not producing

| Author | Message | ||||

| JG825 Newbie Joined: 28/05/2013 Location: United StatesPosts: 4 |

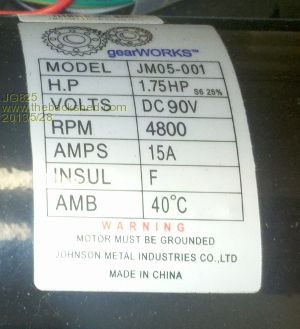

Let me start by saying, I'm a tinkerer, not an engineer. Two years ago I built a three blade windmill using an old treadmill motor. Here is the spec plate from the motor:

I just mounted the windmill on a ten foot pole a few days ago -- I've been busy

My problem is that I am only getting about 3-4 volts when the wind is blowing around 15 knots. My thinking was that if 4800rpm produces 90V, then if I could achieve ~ 700rpm the unit would be producing around 14V which would be good for charging a 12V battery. Where did I go wrong? Is 700rpm a reasonable expectation with 10-12mph winds? Does this motor need to be geared?... The blades are ~ 33" and the unit operates very smoothly. Also, when I was taking the voltage readings, the the voltmeter kept flashing between the 3-4 volts and 0. I had checked the output of the motor with a variable speed drill when I built the unit, but it has been sitting in a garage for the last two years. Thanks. JG |

||||

fillm Guru Joined: 10/02/2007 Location: AustraliaPosts: 730 |

Your problem is the motor , 4800rpm / 90V = 53rpm per 1V , so if you are want to charge a 12V battery then you will need 14 ~ 15 V output so 700 to 800 rpm before you reach charge RPM . I hope the add said " NOT suitable for a wind generator" . Gearing is not worth the trouble , I would recommend looking for something in the 70 to 140 rpm range and keep away from the Car Alternator modded PMAs sold a wind gens in the US. PhillM ...Oz Wind Engineering..Wind Turbine Kits 500W - 5000W ~ F&P Dual Kits ~ GOE222Blades- Voltage Control Parts ------- Tower kits |

||||

Downwind Guru Joined: 09/09/2009 Location: AustraliaPosts: 2333 |

700 rpm is not realistic, and you would need to be down closer to around 100 rpm for cutin to the battery. The motor is a poor choice for a windmill. 4800 / 90 = 53.3 rpm per 1 volt so your mill would have been doing around 200+ rpm for the 3-4 volt output. Pete. Sometimes it just works |

||||

| JG825 Newbie Joined: 28/05/2013 Location: United StatesPosts: 4 |

Guys...thanks for the replies. I had a feeling you were going to tell me that. The motor was out of my own treadmill, so no cost, but certainly some time. I'll look for a lower rpm motor. JG |

||||

| JG825 Newbie Joined: 28/05/2013 Location: United StatesPosts: 4 |

Do you have a recommendation on motor specifications? Thanks. JG |

||||

fillm Guru Joined: 10/02/2007 Location: AustraliaPosts: 730 |

Search for some old F&P Washing machine motors , there is a lot of info on this site and they are a good place to start , or LG have similar motor or electric push bike motors . PhillM ...Oz Wind Engineering..Wind Turbine Kits 500W - 5000W ~ F&P Dual Kits ~ GOE222Blades- Voltage Control Parts ------- Tower kits |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

In some situations like this you can use a chain or gear drive to up the RPM to the motor. There is a definite loss in the efficiency and potential power, but still a windmill making half its potential watts is better that a windmill making no watts, and there are many successful windmills out there using chains and gears. It really depends on what you want to achieve. If you just want to built a windmill to make a few watts and move on to other projects, then I would give this motor a miss an go for something like a F&P as Phil mentioned. But if you would like to tinker with this motor, experiment with a chain drive, and be prepared for a flop, then go for it. Many of us enjoy building and experimenting, even if at the end of the day the results are a little ( or very ) disappointing. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| JG825 Newbie Joined: 28/05/2013 Location: United StatesPosts: 4 |

All the input is very helpful...thanks. I have seen a number of geared or belted motors online and understand it is not as efficient, but I do like to experiment. I am not familiar with "F&P" is that an Australian brand? From Fill's post above, I understand that I should be shooting for 70 - 140 RPM motor, but what kind of power should I be expecting... i.e. watts, or HP? Most of what I am seeing on ebay are small gear motors. Thanks. JG |

||||

| olddawgsrule Newbie Joined: 03/09/2013 Location: United StatesPosts: 4 |

I'm new here and the site was recommended by a friend. I'm working on a spreadsheet that computes if a motor is worth the time/energy as to what the possible outcome can be. I agree with the premise of rpm to voltage. That I believe I have proven through my own tests. It's can the amperage be factored the same way? RPM/Amperage = RPM per amp?? This I'm about to test for myself, because I haven't heard anyone yet say "yea or nay".. Of course the second question is: Has anyone here already done this?? |

||||

MacGyver Guru Joined: 12/05/2009 Location: United StatesPosts: 1329 |

Crew See, this brings me back to why I use windmills to compress air. With a bountiful supply of compressed air, you can use a car alternator powered by a "steam" engine modified to run on compresse air and it will spin fast enough to actually make the magic happen! I know I'm beating a dead horse, but IMHO a near-ground-level VAWT pumping air beats the crap out of a complicated jenny atop a pole, whirring and yawing. I'm no longer trying to convince anyone; it's just "my" thing. I'm headed to California tomorrow for a two-week hiatus. When I get back to my little piece of heaven (Texas) and since my house is pretty much finished, I'll start building again. First up will be a small(ish) VAWT with a swash-plate drive mechanism pumping air. I'll post the build in a thread of its own. By the way, this VAWT will be similar in design to the GINORMOUS one (20' diameter) I promised to build back in the day. First things first and now that my house has been repaced after a tornado took most of it to Oz (the imaginary Oz, not Australia) I now have time to tinker in the shop again. . . . . . Mac Nothing difficult is ever easy! Perhaps better stated in the words of Morgan Freeman, "Where there is no struggle, there is no progress!" Copeville, Texas |

||||

| powerednut Senior Member Joined: 09/12/2009 Location: AustraliaPosts: 221 |

Sorry to hear about your house mac... looking forward to seeing the results of your tinkering - flog that dead horse! its got some miles left in it.. |

||||

| olddawgsrule Newbie Joined: 03/09/2013 Location: United StatesPosts: 4 |

Mac, Have you started a thread on this concept? I'd like to read up a bit on this. |

||||

| Don B Senior Member Joined: 27/09/2008 Location: AustraliaPosts: 190 |

Hi JG As others have been saying, you have picked an unsuitable device for your experiments. The basic problem is that your device was designed to operate as a motor with a 90V power supply, and to turn at 4,800 RPM. To operate as, say, a 90V generator, you would have to turn it even faster - maybe 5,000 rpm, or more. At a typical direct driven wind generator speed of somewhere less that 500 rpm, you will get less than 9V output, and with the following shortcomings: The motor stator will be wound with thin wire which will have a high resistance, and hence high losses for operation at much lower than its rated voltage. The stator winding will have many turns of wire, so its inductance will be high, which will also limit its current output under load. To further complicate things, the larger the turbine diameter, and hence potential power output, the slower it will turn. More blades will only cause it to turn more slowly. You need to have a look at the many articles available on tip speed ratio. What you need to produce a useful amount of low voltage power is a low speed low voltage motor or generator - preferably with a permanent magnet field. Note also that low speed devices need to have a significantly larger diameter than your motor to produce useful power effectively at low speeds. I hope that this encourages you extend your experiments into areas that will give you more worthwhile results. Regards Don B |

||||