|

|

Forum Index : Windmills : Variable Pitch Design

| Author | Message | ||||

| Don B Senior Member Joined: 27/09/2008 Location: AustraliaPosts: 190 |

Hi again mad monkey 2, and hi Midwoud 1. I was prompted to have a look at the Fieldlines thread on this topic (all 16 pages of it), and I came away vastly impressed with the efforts of Franz (Midwoud 1) over the space of 3 or more years with the evolution of his variable pitch design. The only comment that I have is that Midwoud's variable pitch facility seems to be being used only to limit speed (to some arbitrarily selected rpm value?), and to stop generation when his battery is fully charged. A pity, because it has further capabilities if the additional power can be used. The starting point is to accept that the aim should be to make the most power possible with his rig from any given wind. This means that it must operate with maximum efficiency. As pointed out by Warpspeed in an earlier post, there is no benefit to be gained from running a DC generator at a constant speed, or from arbitrarily limiting its speed to some nominal value which may be below its safe maximum speed capability. With an ideal arrangement, if the DC generator was able to double its speed, then it could deliver four times more power. Unfortunately, the usual set-up of charging a more or less constant voltage battery with the output tends to lock the generator to low revs and hence limits the power output to something less than this. With fixed pitch blades, there will be a particular ratio between wind speed and rotational speed where the most power will be delivered. If the wind speed doubles, then the rotational speed also needs to double. This relationship is known as the tip speed ratio, and should form the basis for design of the aerodynamic qualities of a turbine blade. If the blade pitch can be varied, then the tip speed ratio can also be varied within limits, meaning that the turbine speed need not strictly follow wind speed variations. While some efficiency will be lost running off the optimum tip speed ratio, more power could be delivered as a consequence of a pitch change. Two quantities are needed to gain more benefit from pitch changing. These are the wind speed at the turbine, and the position of the pitch change mechanism (ie the blade angle). Perhaps the best place for the wind speed anemometer is above the turbine, though it needs to be probably about one blade diameter or more higher to avoid being affected by the airflow through the turbine. Blade angle could be measured by a linear potentiometer attached to the pitch change mechanism. The idea is to simultaneously monitor (or preferably log) wind speed, power output (amps or watts), and blade angle. Although the wind constantly fluctuates, it should be possible to find the blade angle for a given wind speed that produces the most power. This could ultimately be incorporated in a look up table so that your control system automatically sets the correct blade angle for any given wind speed. Incidentally, using large increments of blade angle change (ie long time impulses) will cause over-correction. Keep them small. Regards Don B |

||||

| Midwoud1 Newbie Joined: 25/12/2012 Location: NetherlandsPosts: 23 |

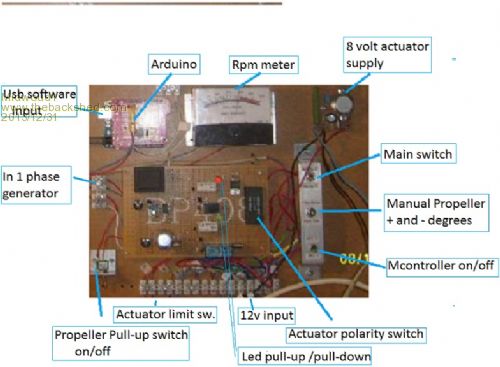

With the Arduino you can make all settings. Duty cycles in milli-seconds. After charged batteries auto switch to dumpload, Hot water, Heating. Also free-run with high Rpm and safety pull-back. Auto start and stop with a timer or anemometer. Stop at high stator temp. All wireless info readout on laptop or PC or Tablet ,Smartphone. Rgds. - Frans -

|

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

This concept is called "feed forward" you use windspeed as the input parameter to access some previously worked out values for optimum pitch correction. Or for PWM duty cyle correction. There are several advantages, including very fast response to large sudden wind speed changes, and no possibility of instability. With any type of closed loop "feedback" system, especially an MPPT system which always rocking the pitch back and forth slightly, trying to see if the electrical output increases or decreases with each change. This not only has to be a fairly slow process, it can also become unstable. The MPPT system can increase the loading causing rotor speed to fall, it then decreases the loading causing the speed to become too high. It can then endlessly cycle, unless you really slow down the rate of correction. A feedforward system has none of these instability problems that feedback systems can have. And can be used for many different types of control solutions where very rapid speed of response with total stability are required. Cheers, Tony. |

||||

| jorn Newbie Joined: 30/12/2012 Location: NetherlandsPosts: 22 |

Windmillfriends, Cooperation is the key to implement all of the above written in our small turbines. |

||||

| anteror Senior Member Joined: 06/10/2009 Location: FinlandPosts: 189 |

I have tested several.. windgenerators.. My story; http://www.thebackshed.com/forum/forum_posts.asp?TID=5285&PN =1 Best result gives 48v windgenerator to load 24V system.. I have tested also 24v, but.. With low winds I get MUCH more power and with high winds, it is just the same is it 24V or 48V wind generator. My generator; http://www.huayaturbine.com/ Without pitch control and the storm protection is with offset and rudder furling. Very unstable in the wind direction.. and you get a fraction only from the power of wind.. This is what I want to say to this; I have very high average wind speed, but we need a wind generator to suite for ALL conditions, to make real energy. As I wrote; http://www.thebackshed.com/forum/forum_posts.asp?TID=6194&PN =1 Blades are small and made with compromise. With this variable pitch control, you REALLY can oversize blades and their efficiency, to make energy with LOW.. winds and ALSO in every storm conditions. Considerably more torque and power, from the wind ! This will REALLY give possibilities, that are not possible to protect against.. any storms, with this blade efficiency, lenght etc.. without pitch control. They would be very noisy.. RPM etc With pitch control also the rudder is exactly aligned with the wind turbine and can be/ should be LONG, to stay in the wind direction. That gives MUCH more.. power in all wind conditions, compared to the system in many "other" wind generators that have storm protection with offset and furling.. Offset / Furling ; http://translate.google.fi/translate?sl=fi&tl=en&js=n&prev=_ t&hl=fi&ie=UTF-8&u=http%3A%2F%2Fwww.poikkis.net%2Ffurling.ph p&act=url Very good and detailed presentation of this; http://www.thebackshed.com/windmill/docs/furling.asp If there is any help for this, from my testing and experiences. This IS ! a very good beginning

Antero |

||||

| jorn Newbie Joined: 30/12/2012 Location: NetherlandsPosts: 22 |

Antero, We see photos of your activities in windenergy. What is your problem to make a turbine with active pitch control, and is there a way to support each other? Greetings Jorn |

||||

| anteror Senior Member Joined: 06/10/2009 Location: FinlandPosts: 189 |

I do not want to make my own wind generator and if you read "my story" in the previous message, I wanted to found Factory made and robust machine and with the price that is reasonably. That I found. I will wait, until I get a robust and cheap pitch controlled factory made with reasonable price. What I wanted to say, was my experiences about small wind generators, in my use and testing, for a long period. PERFECT.. wind generator

After all.. it would be very easy to manufacture, nowadays ! The price in mass production, very cheap ! Antero |

||||

| jorn Newbie Joined: 30/12/2012 Location: NetherlandsPosts: 22 |

Make low budget a small robust active pitch controlled turbine. That's what we are trying to do, and we like to get in touch with other constructors. Jorn |

||||

| anteror Senior Member Joined: 06/10/2009 Location: FinlandPosts: 189 |

Thank you Jorn ! Please, let us all know about this. I will write in every forum, some and news etc etc about that, when you get it ready ! That would be a KILLER aplication, for the market..

CLEAR sky energy 24/7 from your own yard..with a perfect wind generator !! That is better than anything else in our time now. Make it happen 2014 !

Antero |

||||

| jorn Newbie Joined: 30/12/2012 Location: NetherlandsPosts: 22 |

Searching for that Killer application is a struggle. like Midwoud en M.Bouwer do on the Dutch Forum http://www.ecologieforum.eu/viewtopic.php?f=23&t=2566&start= 240 |

||||

| domwild Guru Joined: 16/12/2005 Location: AustraliaPosts: 873 |

Jacobs: The only engineering problem I can see raising it ugly head is milling the spiral into a pipe to make the spring-loaded blade turn once the blade wants to fly out radially. The second problem is finding the right spring to match the "spring-braked" centrifugal force to the required pitch at a certain RPM. Why not copy the Jacobs part's dimensions into a CNC milling machine and test the Jacobs springs to get matching ones? The patent must have has expired by now. Taxation as a means of achieving prosperity is like a man standing inside a bucket trying to lift himself up. Winston Churchill |

||||

| anteror Senior Member Joined: 06/10/2009 Location: FinlandPosts: 189 |

To Jorn; You in the Netherlands have the best.. and very long history about using wind power. You dried your land to make it overall habitable and for cultivation. You made the biggest and most successful commercial sailing fleet in the world with wind powered saw mils etc Some History about that; http://www.resilience.org/stories/2009-10-21/wind-powered-fa ctories-history-and-future-industrial-windmills http://calculating.wordpress.com/2012/06/06/forgotten-histor y-wind-powered-sawmills/ http://www.holland.com/global/tourism/article/dutch-windmill s.htm With this history, it's no wonder.. Rotterdam in your country remains to be the biggest port in Europe and is one of the biggest in the world. You can sail in the oceans and winds, in this world ! SO.. This pitch controlled killer application.. that would only be a natural part to continue your successful wind power history and conquering the world

Good tailwinds for that, too ! Antero |

||||

| Midwoud1 Newbie Joined: 25/12/2012 Location: NetherlandsPosts: 23 |

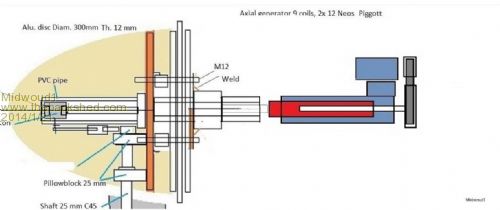

Pitch controlled blades. Over the last few years we have been looking for a suitable actuator. I made my own of a cordless drill, (after 2,5 years still working good ) 2) A factory product, should be with limit switches. 3) An actuator of an electric booster. 4) An actuator of a hospital bed or satellite dish. 5) A rotary-nut and threaded rod motor. 6) A car window opener.

|

||||