|

|

Forum Index : Windmills : The Latest from ART Turbine

| Author | Message | ||||

Downwind Guru Joined: 09/09/2009 Location: AustraliaPosts: 2333 |

I would have expected a F&P motor would have been within its power range, also rather fitting as the mill looks like a oversized agitator from a washing machine. First impressions of the mill in motion is impressive, but after a while it becomes in your face and annoying, fine if its in a local park where it has impact and you can walk away from it, but if you are a neighbour looking at it all day everyday it soon becomes an eyesore. To me a small scale mill should blend in and have as little impact on other people that also have to look at it. Watching your mill long enough would drive you crazy (hint) Pete. Sometimes it just works |

||||

| Drewartturbine Newbie Joined: 09/08/2011 Location: Posts: 30 |

Hi Greenbelt, Right now my 72 pair of ceramic mags each have a magnet face of 4" radial, and 1" across, each about 3/4 apart at closest point 1" tall. What I'm looking at switching too is 1"wide, 3" radial and 1/2" tall. These will end up with a minimum distance of closer to 1" if I space them to the outside. I'm very interested in gaining understanding around magnet spacing. What my crude understanding is, is that magnet lateral spacing should be approximately the same, or greater than the total gap (magnet face to magnet face). Does that makes sense? Hi Gizmo The small turbine, the one I tested using a de Proney brake, with engineer Jon Scott, who calculated .29 Cp, was 1.85 Sq meters swept area. We found that occurred at TSR's between 1.3 and 1.4 That's all in the report. report I agree, the calculations of potential energy are simple, and you can see the results in the report on my website (link above). The new turbine is 2x as tall, and 4x swept area, with a few vary slight changes in geometry. Antidotally, it seems to be performing better than the 8ft, which is to be expected because of the higher Reynolds number. I'll report more on that when I'm more confident in it. An alternator design issue with a high solidity low TSR turbine is low rpm operation. This is a significant mechanical design advantage, as the turbine doesn't face nearly the centrifugal loading. 2013-11-28_164630_Performance_Table_Windspeed_Cp_TSR_to_RPM_ and_Watts.pdf What you will see from this table is that my output at design startup of 10km/hr wind speed is likely between10- 30W shaft power available, at between 26 and 39 rpm. Roughly 1W/RPM At design max 40km/hr we may have greater than 2000W available, at between 100 and 150 RPM. Roughly 20W per RPM It's not a lot of RPM, and MAY necessitate going to a belt/chain/rimdrive/gear system. What I found was that my 140lbs of magnets, using test coils, might have given 1W/rev, but not 20W. What I also found is that the larger turbine seems to be producing more shaft power than I expected, so to be safe I should be aiming for closer to 30W/rev. If I switch to rare earth magnets of 1/3 the volume of my existing ceramics, my magnet costs quadruple (from 70$ to 300$) but my available flux should be around 80X. That I'm hoping will do it. Does that sound reasonable? I realize that going to an alt like this necessitates PWM control to keep the alt from dragging down the turbine speed. I'm ok with that. Pete, Sorry you don't like it, most people do, lots have watched it for fairly long periods of time, and I've had 2 of them sit right outside my window for a year. Maybe I'm crazy, maybe you are, maybe just a negative person? Are you working on something better? I look forward to seeing it. Best Drew |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

How are you calculating "swept area" for your turbines. Swept area for a VAWT that's shaped like a cone doesn't make any sense, the swept area would depend on height from base. Maybe swept volume would be more applicable. What you want is the area from the side, the area facing the wind. Then we can get an idea on how much power it can harness. Sorry but I've seen this before, especially with VAWT's. Its all about the area facing he wind, which is why HAWT's are so easy to scale up and VAWT's are not. I do think you need to get one of these machines up in the air and producing power before you invest too much more time and money into it. Cp means nothing if it cant capture enough wind. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| Drewartturbine Newbie Joined: 09/08/2011 Location: Posts: 30 |

Hi Glenn, Thanks for the question. Swept area for VAWT's has normally been calculated by taking the a cross sectional area of a plane passing through the radial center of the swept volume. In other words, if you have a 1m dia rotor, 1meter tall, it's a 1sqm turbine. That's what I've done, does that sound reasonable to you? It represents the total area facing the wind. I am not sure I understand what you mean As I understand it there are two reasons that HAWTs have been successful vs VAWT's. The first reason is that HAWT's of reasonable size (10ft dia and greater) have been able to achieve Cp's of above .25 for a long time. The best verifiable performance of a small VAWT, that I have been able to find is from the NREL lab's report (and later verified by the experimental work of Dr. John Dabiri (well worth watching his videos)), of .17. This report also pointed out that the Windspire tested failed repeatedly, and was removed before testing was completed. This was exceptionally good performance, given that typical (see the paper by Ian Ross, link on my website) for a high solidity VAWT was 0.05 Cp. The second reason, which may be more in line with your thinking is that a VAWT, and most especially a high solidity VAWT by nature uses more material. This is a geometric reality. The ART Turbine is on par with the best small HAWT's (Bergy, SWWP ) in Cp. It's shape, and other factors around it's design work together to allow it to be manufactured from very low cost materials, so while it is using more material, it can be much less expensive material. Also because it is a VAWT, and therefore doesn't have to undergo the precessional forces present when a HAWT is reorienting to face the wind, the loads on the turbine are also less. Thanks for your question Glenn |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

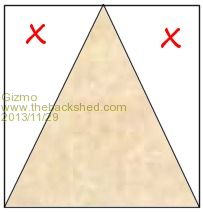

No, that's not correct. From the side, where the wind comes from, your windmill has a triangle shape, not a rectangular shape. Therefore the area facing the wind is less than Width times Height. So using Width times Height is not applicable to your windmill. I know its not a pure triangle, but imagine it is, see the pic below. Your windill is not harnessing the energy in the wind shown in the area X. In fact, if it was a true triangle shape, it would be harvesting half the energy of a similar sized VAWT with vertical sides, like a H rotor or Savonius.

So you need to accurately calculate the area of that triangle, as seen from the side, and then calculate the available power. The same applies to the Darrius turbines, the round egg beater shape means they cant use the width and height formula to calculate area facing wind. The reason HAWT's are easier to scale up is because you gain much more area facing the wind with a smaller increase in diameter than a VAWT. For example, doubling the diameter of a HAWT will give 4 times the area. But doubling the diameter of a VAWT will only give twice the area. And its very easy to extend blades on a HAWT. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| Drewartturbine Newbie Joined: 09/08/2011 Location: Posts: 30 |

Hi Glen, I agree with what you you are saying in terms of measuring swept area, and my turbine is 1m in dia, and almost 3m high, with a swept area of 1.85 sq meters. This was taken by having the turbine mounted horizontally, then using a plumb bob, (while rotating the turbine to ensure that the whole swept area, not just the frontal area was fount), points on the floor were marked, and the area calculated from there. I'm going to be quite busy for a week, so probably won't have time to post again for a bit. Best Wishes Drew |

||||

| Air Bender Senior Member Joined: 25/01/2011 Location: AustraliaPosts: 206 |

Hi Drew In my mind I think the 2000w power output you are aiming at seems a bit unrealistic, I think if you could produce 500w you would have a very successful VAWT, even 300w would be good. I think if you aim to high you will keep hitting dead ends with your alternators. When you work out your outputs on paper it is easy to over estimate. It is not the same as real time output. I think if you start of with lower expectations, they will be easier to achieve and you will make better headway. Then you can slowly build up. All the best Dean. |

||||

Downwind Guru Joined: 09/09/2009 Location: AustraliaPosts: 2333 |

Well all i can suggest you best check the 2 peoples pulse as they might actually be dead by now. Im not a negative person and in many ways commend you on your work with design and its visual effect, as i said great for a park light application, where it might appear to produce lots of power, and if not its a great visial effect to a public location. There is a market there with attracting attention to wind energy, but for the home user it's no more than a wind art turbine. You dont seem to listen to advice and expect a HUGE output from it, in reality it has a rather small catchment area compared to what you think, it is of a design where high speed can be reached with less drag, but its all a little useless until it is loaded with an alternator that matches the power output range. I would suggest a starting target range of 250 - 500W, because your 2Kw output is WAY outside the ballpark, and more wishful thinking than practical. To date all you have is a twirling top that is still yet to produce power to a operational level. To be honest you are off to a fair to display something that looks great, but it dont actually work yet. Scale down the output expectations and you might just get a result to work with. Work backwards and start low output and work your way forward, as its far easier to see where the mill flatlines on output, compared to over loading the mill that it never gets out of stall to start with. That is why i suggested the F&P alternator, as i think it might be a workable match for a low cost solution, for a off the shelf product. If you keep expecting a 2kw output, than we will still be replying to your threads years from now with the same answers. From ....Mr Negative, (but realistic ) Pete. Sometimes it just works |

||||

| Air Bender Senior Member Joined: 25/01/2011 Location: AustraliaPosts: 206 |

I tried a F/P on a vawt and the revs are a bit to low to make any decent power, I think it would work if it was geared, but the mill will need to be strong to push it up to speed. The advantage a HAWT has is that it has a power band that kicks in when the blades reach the speed where they start to produce lift. If the cut in is set at the point were the power band kicks in, it will start to push out the amps. After building both Vawts and Hawts, it clearly stood out the advantage the HAWT had and were the VAWT was failing. Drew I hope you are not thinking that I am trying to be negative, what I am trying to do is pass on my experience. You have a very nice design, but getting the alternator right is going to be the hard part. All the best Dean. |

||||

| Air Bender Senior Member Joined: 25/01/2011 Location: AustraliaPosts: 206 |

Drew if your mill only makes 250 watts it will still be a success, people will just have to buy more of them, they could even line there drive way with them. All the best dean. |

||||

| Greenbelt Guru Joined: 11/01/2009 Location: United StatesPosts: 566 |

Hi Drew; You need to think about the magnet shape you choose to install. if I have read your post correctly?, the radial space is to be three inches. this will kill any advantage the large radius could offer, this is 3 inches between coils in a single magnet-coil sequence. if you have a double row of mag's with the stator coils sandwiched between ( Axial) then your flux will be nullified due to the small width (1/2 inch) acting on a coil base of an inch + and a long way across the center of the mag where there is no flux. edit, (you need to close the distance to 2 inches if possible) ee Magnets should be round or oval to have the most effect, a rectangle is ok if its very short, this keeps the flux local and intense. Some of the Members on this forum have spent a lifetime working back yard wind. they have spent much money and vested untold hours to make it work better, when is seems that a reply is negative its because they have been there, done that. I am not one of them but I read a lot. There is many pages on this Forum that can offer guidance. --------------Cheers Roe Time has proven that I am blind to the Obvious, some of the above may be True? |

||||

| electrondady1 Senior Member Joined: 12/02/2009 Location: CanadaPosts: 208 |

as a vawt builder, i can tell you why a hawt is more efficient. it's because all the blades are being powered by the wind all the time. as opposed to a vawt that has one vane being pushed by the wind and another being dragged around into the wind and is absorbing power in order to do that. |

||||

mac46 Guru Joined: 07/02/2008 Location: United StatesPosts: 412 |

Well,maybe not quite correct. As far as my testing has developed,,,and mind you, I have much more to learn and many more tests to do...as the Vawt comes up to speed all of the wings start to produce lift and contribute to the rotation, a slight vaccume is created in the interior area of the machine, and air is pushed out the top and bottom. There is also many other areas around the wings creating localized vortices and this varies on the wind direction, strength, as to what area of the turbine and how pronounced they are. This effect will change depending on what type and size of the wings, as well as how many wings. I'm sure that the diameter, height, ect. ect. also effects all this as well. This is concerning the 'H' rotor style Vawt. So far I'm not sure at all as to what would be best, but I am pretty sure that it would depend on you'r location conditions and average wind speed. Mac46 I'm just a farmer |

||||

Downwind Guru Joined: 09/09/2009 Location: AustraliaPosts: 2333 |

O-well if it dont actually ever produce any power you could always sell it to a icecream factory for roof art. Theres a thought  wind powered Mr Whippy Icecream Vans, all you need to do is add a bell. wind powered Mr Whippy Icecream Vans, all you need to do is add a bell.

Pete. Sometimes it just works |

||||

| electrondady1 Senior Member Joined: 12/02/2009 Location: CanadaPosts: 208 |

yea, but Mack your describing a Darius type vertical mill like the big one you have built, were each blade has a lifting profile. or one of ed's lenz2 machines that has a hybrid drag /lift profile based on stal aircraft. that's not what Art has built. it's a solid centre . it's a drag machine. |

||||