|

|

Forum Index : Windmills : VAWT, F&P, analog MPPT project

| Author | Message | ||||

Downwind Guru Joined: 09/09/2009 Location: AustraliaPosts: 2333 |

I too marvel at your "clockwork skills" dont get me wrong that your work is not creditable, its clockwork in motion. My view is the energy loss involved in the design. Personally i think a Vawt is a pure waste of time for what can be extracted for the energy involved to drive it, in most cases its less than 50% what can be achieved by a Hawt in the same winds. So you see i am sceptical about what you think is a efficient Vawt design, compared to what?, and tested with what method to achieve a result. Time has proven to me data logging shows a far different result over time than what you think is the case from a few meter readings in on a good wind day. Please progress with your build, its interesting, if nothing less than seeing the good work you do and the trouble people go to for reinventing the wheel. Just remember introducing losses is a slippery slide towards the point of no return. Pete. Sometimes it just works |

||||

| govertical Guru Joined: 11/12/2008 Location: United StatesPosts: 383 |

Hi, I recently made a modification to my VAWT that may help reduce the mechanical power loss that is added from the gear drive. I am able to add a smaller set of blades to the output of the gear drive. Large blades are attached to the input. The smaller blades help start the rotation in low wind conditions. It is just something I had to try. Comments are welcome. Video of dual blade set no load transmission VAWT just because your a GURU or forum administer does not mean your always correct :) |

||||

| govertical Guru Joined: 11/12/2008 Location: United StatesPosts: 383 |

Gear Program Hi, the above link is the program I use to create the gears. The MPPT controller I am currently testing is the MPPT25 from intronics. It is a solar MPPT controller and solar MPPT controllers do not work with PMA's. I contacted the designer and he wrote new code so it would work for a PMA. The code I am using now limits the duty cycle to a max value 30% and the MPPT algorithm tracks the Vin as long as the wind speed does not change rapidly. Using a hand crank to manually operate a modified F&P stator the highest current output into a 12 volt deep cell was 7 amps. The main problem is the input voltage limit of the MPPT25 is 80 Volts DC and even after modifying the F&P stator high winds drive the voltage above 80 Vdc and damage the controller. I have sent it back for repairs two times so far, which is why I built the Pgen to finish designing the over voltage protection circuit.

I have four F&P's. I have tried all the stator modifications and have found the stator with the lowest internal resistance works best. I recently had a hard drive crash and lost about 6 months of work, so for now it is like starting over. I look forward to your test results. The plan for my project at this time is to finish the needed OVP circuit, fabricate more VAWT's, and operate them in parallel.For me VAWT's are low cost, easy to fabricate, and safe. The downside is I need more the one. just because your a GURU or forum administer does not mean your always correct :) |

||||

| govertical Guru Joined: 11/12/2008 Location: United StatesPosts: 383 |

Hi fillm, the numbers generated by the VAWT power calculator for your size blades and wind speed are what you are aiming for. Then if you need more amps, build more VAWTs and run them in parallel. A bunch of small VAWTs operating in parallel I believe is better than one big VAWT. just because your a GURU or forum administer does not mean your always correct :) |

||||

fillm Guru Joined: 10/02/2007 Location: AustraliaPosts: 730 |

I will base the VAWT on a single 60S and the 3 x 1m Alu GOE222 blades that I sell , and will only be as a trial to help others as I get asked for info and help frequently about how best to use these blades with VAWT designs and I know a lot have been used as VAWTs and I have sent them all over the world to uni's ,private builds, including CalTek. What is annoying with most of the VAWT builds and Videos posted on the internet is there is no "actual" output data posted and 99% of the videos are taken in an unloaded state, I have lost count of how many times I have seen the "VAWT Power Caculator" Link ,thrown in as a reference as to what to expect . I doubt that with what I come up with will have any startling output figures either but what I do have is all the logging hardware & programs to accurately record and can pretty well pre-empt the results , that the same 3 blades will output 4X the power configured as a HAWT, so in reality why build 4 VAWTs to give the power of 1 HAWT. But Hey , people seem to be fixated on VAWT design ( Visual Art Wind Turbines ) and are not overly concerned about power output. PhillM ...Oz Wind Engineering..Wind Turbine Kits 500W - 5000W ~ F&P Dual Kits ~ GOE222Blades- Voltage Control Parts ------- Tower kits |

||||

| govertical Guru Joined: 11/12/2008 Location: United StatesPosts: 383 |

Hi, I am not trying to be annoying, but that is the point of the CalTech study more inefficient VAWT's will produce more power per square meter of land then HAWT's. VAWT's cost less, are safer, and are easier to fabricate. The reason why the VAWT video's never post data is because they do not know the high internal resistance of the PMA stator is causing the VAWT to stall. A MPPT circuit the needed to prevent the problem. just because your a GURU or forum administer does not mean your always correct :) |

||||

Downwind Guru Joined: 09/09/2009 Location: AustraliaPosts: 2333 |

That sounds like rubbish to me, due to the fact a Vawt should have high torque compared to a Hawt, and a Hawt works. The problem is a PMA needs rpm to generate high enough volts and a Vawt is simply too low in rpm to work efficently. To me a vawt is like building a mo-ped where you need to add pedals to assist the motor, compared to a Hawt where a better design results in a moto-bike and no need for the extra junk to make it work. Adding enough crap to a bad design of anything can make it work, but that dont make it a good design to start with. VAWT = Variable Amounts of Wasted Time. Sometimes it just works |

||||

| govertical Guru Joined: 11/12/2008 Location: United StatesPosts: 383 |

Hi, take 40 minutes and watch the CalTech video...  just because your a GURU or forum administer does not mean your always correct :) |

||||

fillm Guru Joined: 10/02/2007 Location: AustraliaPosts: 730 |

No Thanks , its a bit like watching paint dry, rather watch an amp/meter on a HAWT. PhillM ...Oz Wind Engineering..Wind Turbine Kits 500W - 5000W ~ F&P Dual Kits ~ GOE222Blades- Voltage Control Parts ------- Tower kits |

||||

| govertical Guru Joined: 11/12/2008 Location: United StatesPosts: 383 |

Hi, I understand. Just a heads up on your VAWT project. I found that lift blade will work better with a air core PMA and drag blades will work better with a iron core PMA. I have tested 3,5,and 6 blade configurations and the 6 blade configuration works best for the style blades I am using. I also tested direct drive and found I had better results after adding the gear drive to the 6 blade configuration. Bottom line, HAWT or VAWT, generating electricity from any renewable resource is a step in the right direction. just because your a GURU or forum administer does not mean your always correct :) |

||||

| govertical Guru Joined: 11/12/2008 Location: United StatesPosts: 383 |

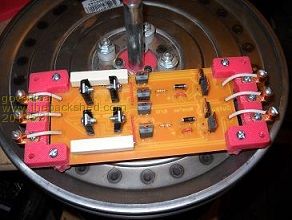

Over voltage protection circuit Testing over voltage protection circuit with pedal generator using 12 volt light as a test load. After the OVP is triggered the resistive load of the light is placed across the PMA output and the added load forces the RPM to be reduced. When the PMA output voltage decreases the OVP circuit automatically resets. This circuit is required to prevent damage to the MPPT circuit during high wind conditions. The sound that the PMA makes when the OVP triggers sounds like something from star wars. :)

just because your a GURU or forum administer does not mean your always correct :) |

||||

Downwind Guru Joined: 09/09/2009 Location: AustraliaPosts: 2333 |

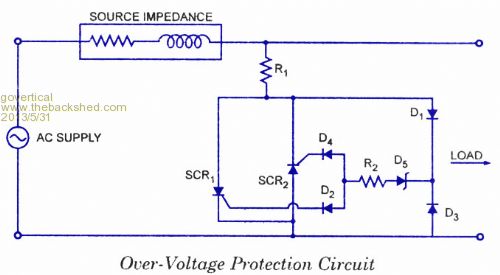

Can you explain how the OVP circuit works, as im a little lost with how it functions across the 3 phases, from what i can make out 2 of the phases are shorted to the 3rd phase, i just dont follow how that works. Pete. Sometimes it just works |

||||

| govertical Guru Joined: 11/12/2008 Location: United StatesPosts: 383 |

Hi, No. This project is my first experience with 3 phase AC power electronics. I found the circuit for a single phase AC crow bar circuit on circuitstoday.com and applied it to what I thought would work for a 3 phase PMA braking application. I do know that anytime the voltage at Z1 or Z2 exceeds the zener brake down voltage one of SCR's fires and the added resistive load across the PMA from the 12 volt light forces the PMA RPM to stall. Hopefully someone with more experience will contribute and provide a better explanation.

D5 = Z1 or Z2 R1 = 12 volt light just because your a GURU or forum administer does not mean your always correct :) |

||||

| govertical Guru Joined: 11/12/2008 Location: United StatesPosts: 383 |

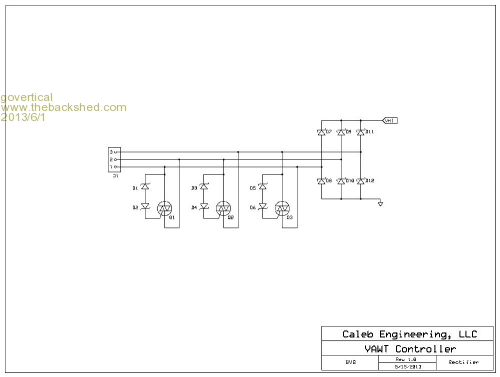

Hi, I found this circuit from caleb at windgen.org of a 3 phase OVP circuit. If I apply the circuit I found and use Caleb's wiring scheme it may provide OVP for all 3 phases. Thank you for asking the question. just because your a GURU or forum administer does not mean your always correct :) |

||||

Downwind Guru Joined: 09/09/2009 Location: AustraliaPosts: 2333 |

There must be something with Vawt builders that fail to see all the work we do in controlling a Hawt, its no difference if the alternator is vertical or horizontal its the outpot power we need to control. Why mess with dumping AC for your "OVP" and simply use a system of a extra 3 phase rectifier and use DC to control the mill like is commom with a Hawt. Its a hell of a lot simpler to switch a DC load then it is to control a 3 phase short circuit method. From the sounds the alternator makes in your video would imply the method you have is not correct. Sometimes it just works |

||||

| govertical Guru Joined: 11/12/2008 Location: United StatesPosts: 383 |

Hi, thanks for the suggestion. Does the DC method brake or reduce the turbine RPM? Are there any links available showing a circuit for the DC method? just because your a GURU or forum administer does not mean your always correct :) |

||||

fillm Guru Joined: 10/02/2007 Location: AustraliaPosts: 730 |

GoV, I posted a diagram on 80 / 100 Amp Charge Control Thread HERE and is basicly the resistive type braking like what Pete has mentioned, there is another method where you can infinitely vary the AC load with a liquid resistor and this is the thread for that HERE , at the end of the day I would think it would be a balancing act to find the correct resistance , as your OVP turns on if the resistance is to great then the OVP will instantly see the a lower voltage and turn OFF , so in that situation it will produce its own frequency and if std contacts are used they will be destroyed quickly . You have chosen an expensive & heavily reliant on electronics path to go on for very little gain , with your ability with the mechanicial solution, why would you not do a Flyweight Governor Brake to limit RPMs . The other opt is to go to a higher Voltage MPPT like the Midnite Range . PhillM ...Oz Wind Engineering..Wind Turbine Kits 500W - 5000W ~ F&P Dual Kits ~ GOE222Blades- Voltage Control Parts ------- Tower kits |

||||

| govertical Guru Joined: 11/12/2008 Location: United StatesPosts: 383 |

video of OVP circuit using 120 Volt AC light just because your a GURU or forum administer does not mean your always correct :) |

||||