|

|

Forum Index : Windmills : aluminum windings on my F&P??

| Author | Message | ||||

| greenlivin Newbie Joined: 05/04/2012 Location: United StatesPosts: 12 |

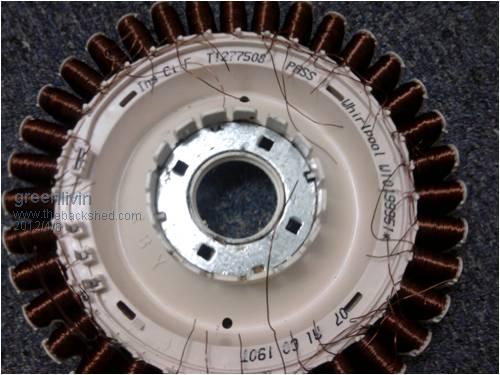

Ok, I'm not new at soldering but nothing I do will get the solder to take to my coil windings which I believe to be aluminum. Can they actually be aluminum and, if so, how can I solder the wires?

I am at my wits end on this one. Please help. Thanks. O'yeah, it's a newer F&P with 36 poles. I thought maybe it was just a coating but I took a razor knife and skinned the wire nearly down to nothing and still no copper and it's way too flimsy to be anything else that I can imagine other than aluminum. Thanks. |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

Hi greenlivin Thats news to me, but its possible, I've seen aluminium used in welding transformers before. It may be a cost cutting move by F&P, copper is getting expensive and aluminium is cheaper than steel some days. You can buy a flux suitable for soldering aluminium. Just dip the wire end into the flux and use a converional iron to melt the solder into the joint. Never used it but I hear it works OK. Or look at some sort of mechanical connection, like a crimp or screw terminal. Hope that helps. If you get a chance it would be nice to see a photo or two. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| greenlivin Newbie Joined: 05/04/2012 Location: United StatesPosts: 12 |

Hi Gizmo. Cool. Didn't know they had anything for aluminum. Yeah, I've actually never seen it used in a coil before which is why I was confounded. I didn't want to use a mechanical connection if I could avoid it. My concern right now is that it may not perform as well as if it were copper. It is only my first attempt but I don't like the idea of putting a lot of work into something that doesn't perform well.

In this pic, I have shaved the wire nearly in half. No copper there.

I was somewhat surprised to pull a whirlpool stator out of a Fisher washer but I 'spose if they put a mitsubishi motor in a dodge .... Let me know what you think. Thanks. |

||||

| Tinker Guru Joined: 07/11/2007 Location: AustraliaPosts: 1904 |

Have a good look at the way the ends of the wires were originally connected. I bet it was mechanical crimping if it indeed is aluminium wire. You could try those little crimp sleeves they use on wire traces to fishing hooks. There is even a neat pair of crimping pliers for these available, not very expensive either. Just visit your local fishing tackle shop. Aluminium wire work hardens even worse than copper so try to keep bending the wires to an absolutely minimum. Once it has gone hard its brittle and might break later on. Klaus |

||||

| greenlivin Newbie Joined: 05/04/2012 Location: United StatesPosts: 12 |

Y I B, M R ducks!!! They do have some kind of solder-less connection originally. I didn't even look at those closely before. Of course, it's my first one so I wouldn't have known the diff either. I did find an aluminum solder kit on line. Sears has them for 14 bucks but I'll probably just go with the crimp things as it's actually cheaper and the soldering was raising my blood pressure

I'll still have to figure out how to connect the individual aluminum wires to the main leads but, I can work that out. Thanks guys. |

||||

TEA20 Newbie Joined: 10/06/2011 Location: AustraliaPosts: 7 |

just curious... whats the weight of the coil section  Muchea W.A. |

||||

| Randysworkshop Newbie Joined: 25/10/2006 Location: United StatesPosts: 10 |

After reading your post, I contacted my inside factory guy at the Fisher & Paykel plant in the USA. He said that they wind the stators made in Thailand with aluminum wire and that the plastic stators were marked with the Whirlpool number for a short period of time. The ones made in the US are currently still wound with copper. Randy B. www.randysworkshop.com randy burmeister |

||||

| brucedownunder2 Guru Joined: 14/09/2005 Location: AustraliaPosts: 1548 |

Hi Crew ,, Yes, years ago ,way back , I got 2 of those F&P "randy-annie" or something named similar ... They were chunky 6 inch square permanent magnet motors wound with Aluminium .. Huge cogging ,many poles .. I tried different configurations with no success. The windings were sort of light brown coated, and ,yes, they were mechanically connected to multistrand fly leads covered in transparent heatshrink.. I just removed the enamel coating with a stanley knife and joined them using those strip joiners .. Bruce Bushboy |

||||

| greenlivin Newbie Joined: 05/04/2012 Location: United StatesPosts: 12 |

Sorry didn't get back to you sooner. I don't know. I don't have a scale to check and I don't have another stator for comparison. It is pretty heavy but I suspect that it is all just the steel inside the poles. Good thought, though. If the performance is in-line with the copper then the weight savings may be worth something with a HWAT up high. |

||||

| greenlivin Newbie Joined: 05/04/2012 Location: United StatesPosts: 12 |

O. Did he know whether or not there was a performance difference between the two? I suppose only time will tell if there will be a longevity issue. |

||||

| greenlivin Newbie Joined: 05/04/2012 Location: United StatesPosts: 12 |

Yeah, I'm running with the idea of using the aluminum fishing leader crimps. Found them at Bass Pro for 5 bucks. 100 to a pack should do it. Hopefully I'll end up with a respectable looking product that will last awhile. I wonder if you could interchange stators to get rid of the cogging or a different power curve from the stator that came with the Randy Annie? |

||||

| Randysworkshop Newbie Joined: 25/10/2006 Location: United StatesPosts: 10 |

Yes there is a performance difference with the aluminum windings! That is the reason F&P came up with the new SD4 magnetic hub. It was designed to go on the American (Whirlpool)stators with the aluminum windings to bring the performance back up to the copper wound ones. Which I believe is somewhere between 18 to 20 percent. Randy's Workshop is offering a copper wound stator with the new SD4 hub with the thought of getting even more performance that a stock unit. Randy B. www.randysworkshop.com randy burmeister |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

I was rather surprised to discover that a microwave oven transformer I am using for a project was wound with aluminium wire. As copper becomes more and more expensive, I think we are going to see aluminium wire used more frequently in many common items. Cheers, Tony. |

||||

| greenlivin Newbie Joined: 05/04/2012 Location: United StatesPosts: 12 |

I kinda figured. Good idea with the hybrid! I'll have to check that out. Thanks. |

||||