|

|

Forum Index : Windmills : HAWT Braking concept advice

| Author | Message | ||||

| Nick 50 Newbie Joined: 27/11/2011 Location: United KingdomPosts: 3 |

Hello, i'm hoping for some advice on a concept for a braking device for a Micro HAWT. The project is part of a University module for Mechanical Engineering. As such we have set parameters for the project. We will be given a 25W motor to be used as a Generator. There will be a load test at 5ms, 10ms and 15ms where the aim is to achieve maximum power output possible. However, the wind speed will be increased to measure the stability of the turbine and also that is must maintain a constant power output which does not exceed the 25W. Due to this we need some type of braking device to maintain a set speed. The idea I have envisaged is some type of circuit that when the power reaches 25W will then channel the excess to an electromagnet which will be situated next to a steel disk on the shaft. The hope that as the excess increases, as does the flux and in turn will slow the shaft down. I understand most micro/mini use furling for high wind speeds but that would cause a sinusoidal power output, which unfortunately will not meet our set objective. My knowledge of electronics is very poor. The question I have is, is it possible to have a circuit that will channel an excess power output into an electromagnet? |

||||

| norcold Guru Joined: 06/02/2011 Location: AustraliaPosts: 670 |

It may be easier to simply "short" the field windings before the rectifier, when the winds are excessive, this will "load up" the PMA. Some wind turbine controllers have this built into their electronics, they sense when the voltage becomes excessive(battery charged) and electronically "short" the field windings. However mechanical furling is still used to ensure very high winds do not destroy the turbine. We come from the land downunder. Vic |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi Nick and Vic It is not a good Idea to short the mill unless it is stopped as the instantaneous current peak till it stops can destroy the windings, Furling is a better answer if you can get it working properly. If you must short the mill have a resistance in the shorting line calculated to dissipate 20% more than the maximum rated output of the mill to load it down gently to prevent cooking the windings, or alternately make it strong enough to withstand high wind events. I have a number of these shorting regulators out of Chinese mills that are cooked from attempting to short out the mill in high winds. All the best Bob Foolin Around |

||||

MrDelanco Senior Member Joined: 12/11/2011 Location: United StatesPosts: 101 |

Hello Nick; Welcome to the club. Yes is the answer to your question. It possible to have a circuit that will channel an excess power output into an electromagnet. However a steel disk on the shaft will when energized slow the shaft down and apply excessive torque to several areas of the system's structural and operational components. And when applied may even damage the structural integrity of the blades depending on the force in the wind when applied. You may want to investigate a disengaging blade hub or blade pitch changing setup using an electromagnet assembly. Regards Robert. MrDelanco:Project Videos It is not only too know what it does but to understand how it does what it does. |

||||

| norcold Guru Joined: 06/02/2011 Location: AustraliaPosts: 670 |

Bob I`m with you to a certain extent, the Oatley controller kit has been succesfully braking my little 200W mill for 4 years plus keeping boat battery topped up, from many revs to stopped many times an hour. But Nick is looking at a 25W mill with furling ruled out. I feel braking using the fields is a consideration in this case. We come from the land downunder. Vic |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi Vic For what is happening with your mill all is OK, I was referring to a high wind event where things where getting out of control. As you say a 25 watt is a different basket of fruit and providing it is robust all should be well. I have managed to destroy a per mag generator on a little plane by it producing to much power, no furling there it was just blowing in the wind to provide back up power for the radio. All the best Bob Foolin Around |

||||

| Nick 50 Newbie Joined: 27/11/2011 Location: United KingdomPosts: 3 |

Thanks for all the replies, i'm very grateful. norcold I'm not sure what a PMA is to be honest?? Also the generator we will be allocated must not be opened or changed in any way. As for rectification, our brief does not mention that there will be any. All it states that: "Must survive testing at 5, 10 and 15 m/s for at least 5 minutes during standard electrical load test" Robert (MrDelanco) We have considered the Torque that would be generated. We are in the middle of getting a design onto a 3D CAD software which will do the analysis to see how much torque is likely to be generated. As for the blades, we are going to use an 3 Blade EP Propeller 15x8 / 381x204mm from a Remote Control Aeroplane. Perhaps 2 sets to make 6 blades dependant on Tip speed ratio from testing. This one: http://www.giantcod.co.uk/blade-propeller-15x8-381x204mm-p-4 04472.html The blades themselves seem very durable and suited for our one off test. As for changing the blade pitch, would that not be more electronically technical? Also you mentioned disengaging the blade hub, which I assume will have the same effect as furling in regards of a drop in the power output? Our first thought for the electromagnet concept is for a small circuit that is attached from the generator with 2 wires that will go to the electrical load testing equipment and 2 wires to go to the electromagnet. It is the actual design of the circuit or even if a similar circuit which has a given name I can research and hopefully modify to suit our needs. I hope all that makes sense. |

||||

| norcold Guru Joined: 06/02/2011 Location: AustraliaPosts: 670 |

Nick, PMA- Permanent Magnet Alternator. It is the alternator of choice for wind turbines(micro) with many on this 4m constructing their own. Google PMA for many descriptions and you`ll see why it lends itself to wind power. All the best and keep us posted with your projects progress. We come from the land downunder. Vic |

||||

Bryan1 Guru Joined: 22/02/2006 Location: AustraliaPosts: 1344 |

Hi Nick, OK you you will have a '25 watt PMA motor' to use. Now what you don't state is the voltage and speed rating of that said motor. Those 2 parameters will determine the size and number of blades you will need to produce any output. Also you state when the PMA reach's 25 watts you need to keep it at that 25 watts, once again at what voltage as that will determine the current produced. The wind power does go up in the 'cube' law but with small blades and a small PMA motor the generator might have to be spinning at a few 100 rpm just to get that 25 watts in a 5m/s wind speed. Now go to 10/ms of wind speed and the input power from the wind is 4 times stronger and at 15m/s the wind is 4 times stronger than the 10/ms. Now here comes the problem, if you set it up to get 25 watts in a 5m/s wind to try and keep it at 25 watts when the wind has picked up to 15m/s will require some decent braking. Best of luck with this but without any more information we are just stabbing in the dark...... Regards Bryan |

||||

MrDelanco Senior Member Joined: 12/11/2011 Location: United StatesPosts: 101 |

Hello Nick; Info needed. We will be given a 25W motor to be used as a Generator. What voltage and rpm is the motor you are using ? There will be a load test at 5ms, 10ms and 15ms where the aim is to achieve maximum power output possible. What type of load test will be preformed and how is the output measured ? The wind speed will be increased to measure the stability of the turbine and also that it must maintain a constant power output which does not exceed the 25W. That it must maintain a constant power output which does not exceed the 25W seems to be in error of the interpretation of the project. Are you sure that it is the watts that must remain constant ? Please supply more info. Regards Robert. MrDelanco:Project Videos It is not only too know what it does but to understand how it does what it does. |

||||

| Don B Senior Member Joined: 27/09/2008 Location: AustraliaPosts: 190 |

Hi Nick, To meet the objectives of your task, there are some fundamentals that you need to take into account. Unfortunately, they are all conflicting and, as with life, you just have to strike the best compromise possible. The power able to be extracted from the wind at any given wind speed is a function of the area presented by the turbine (plus the turbine efficiency). Something with twice the diameter will be able to extract 4 times the power, if the wind speed and all other things remain equal. The power in the wind increases with the cube of the wind speed. Thus, if the wind speed doubles, the same turbine could extract 8 times the power that it did at the original speed, if it is capable. This is one of the main concerns for turbine designers, as the excess of power can easily overwhelm the mechanical, electrical, and structural capacity of a wind turbine installation in strong winds. There is an optimum (and relatively fixed) relationship between the speed of the tips of a rotating horizontal axis turbine, and the wind speed. This is called the tip speed ratio. Single blade turbines (with a balance weight) have the highest ratio, at around 15, and the ratio reduces as the number of blades increases. The optimum ratio for a 3 blade turbine is around 5, meaning that in, say, a 10 m/s wind, the blade tips should be rotating at about 50 m/s. From the turbine diameter (which determines the area and hence the power extractable at that wind speed) the shaft speed can then be calculated. One of the problems with wind turbines is that, as you make them bigger, to catch more wind power, the slower will be the actual shaft speed. The big commercial wind turbines invariably need a gearbox to step the shaft speed up to a useable alternator speed. The higher the tip speed ratio, the higher the possible efficiency of an HAWT. Unfortunately, the trade-off is that, the lower the number of blades, the lower the starting torque, and the harder they are to start rotating. There are two basic types of wind turbines, those that are designed to use lift, as in the horizontal axis machines, and those that operate on drag, as in the majority of vertical axis turbines (excluding savonius, etc). Lift type turbines can extract significantly more power from the wind than drag types. Note though, that there is a limit called the Betz limit that restricts the ultimate power extractable from the wind to just below 60% of its total energy, and the best small lift type wind turbines do well to achieve even half of that efficiency. Turbines with a small number of blades have low starting torque, high TSR’s hence high speed, and high efficiency. Turbines with many blades (eg farm windmilld) have good starting torque, but low speed and low efficiency. One of their virtues though is that turbines with many blades tend to interfere with the wind flow to the following blade, and hence tend to be self speed limiting. Lift type wind turbine blades are not propellors, even though they look superficially similar. A propeller is designed to generate axial thrust to propel something, while a turbine is designed to efficiently produce rotational energy from a linear wind flow. In reality they are quite different, and a wind turbine blade is carefully designed to operate efficiently at low wind speeds, which is where the maximum useful power can be obtained. Because of the huge increase in energy available as the wind speed increases propellors (and in fact damn near anything with angled blades) can be made to turn a wind generator, but not efficiently. You need to look carefully at the many available texts on wind turbine blade design to understand this. The Permanent Magnet Alternator (PMA) that has been offered for use with your task needs to be carefully assessed, as it is the key to achieving your target, if indeed is possible. At the very least, you must obtain its name plate details. Specifically, you need to know the rotational speed, voltage, and current at which it achieves its nameplate 20 Watts output. Many PMA’s need to operate at a shaft speed which is way higher than that which you can achieve by direct coupling a turbine to it (turbines of your size will only run at maybe 200 to 400 rpm). Don’t forget also that the more power that you try to obtain from a turbine for a given wind speed, the larger will be its diameter, and the slower its rotational speed at any given wind speed to keep itself within its design TSR band. One advantage that you have is that the load of the PMA has not been specified. The simplest load would be a resistor, maybe a variable resistor. Don’t forget though, that the energy delivered by the PMA will be converted into heat, and you will need to get rid of it somehow. The optimum load for your PMA for maximum power transfer would be a resistance that is equal to the resistance of the PMA windings. The best way of determining this is to drive the PMA at a modest fixed speed, and measure the current that flows with the windings short circuited, and the voltage that is produced at the same speed with the windings open circuited. The PMA resistance is simply the voltage divided by the current. As the speed of the PMA increases, its output voltage increases in proportion. You could correspondingly increase the value of the load resistance so that you are still only dissipating 25 Watts at any shaft speed. All that you need to remember is that Power = Volts by Amps. As you increase the load resistance, the volts will rise and the current will fall. All you need to do is alter the resistance so that the product of Volts by Amps is constant (at 25 Watts, hopefully). A simple variable resistance could be two moveable conductive plates dipping in a salt water bath. Be careful of any gases evolved though. Your idea of using a permanent magnet and a disc as a brake is certainly feasible, but probably more complicated that simply varying the load resistance. The torque absorbed by the brake will be a function of the closeness of the magnets to the disc, and the radius of the magnets from the disc axis. Power (absorbed) is the product of torque and speed. Remember though that, as for the load resistance, the power absorbed by the brake will be converted into heat in the disc, and you may need to provide some cooling. You have been handed a most interesting challenge by your lecturer, and I hope that you take the opportunity to delve a little into the complexities of windmills. Good luck Don B |

||||

| Nick 50 Newbie Joined: 27/11/2011 Location: United KingdomPosts: 3 |

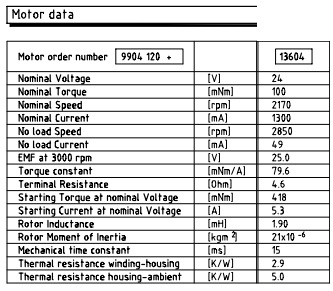

Hi and thanks again for the responses. The generator that we will be given to use is a Premotec DC Coreless CL66-25 Watt Motor. As far as i'm aware it will be the 24V motor which has the values of:

Datasheet: http://www.premotec.com/pdf/coreless/CL66-25%20Watt.pdf Further Data provided: 2011-12-02_062210_Power_Management_24V_Motor-generator.pdf Propeller Choice In Phase 1 of the project our team and sister team were given a Desktop PC and printer and asked to design and create both a HAWT and VAWT windmills only from the parts contained in the 2 components. We managed to produce a downwind HAWT that functioned fairly well. 2 of the main areas which we deemed weakest was its self righting mechanism (design flaw) and the blade balancing which was slightly out. This caused quite excessive vibration within the setup. Due to this we knew that in the Turbine phase we had to ensure that the blades were as perfectly balanced as possible. When researching blade designs I stumbled across a project that used RC Propeller blades. They seemed to function well in the video of the turbine operating. I proposed the idea to the team and also the cost (under $5 US). We know that using them will not be the most efficient but it will mean we have very good blades which are perfectly balanced. Also to note, we are restricted to a maximum diameter of 400mm for the blades. We have our Design & Manufacturing Lab session once a week and we are hoping tomorrow we can test a 3 blade and then 6 blade set-up. From this we will hopefully know the RPM of the blades with an approximate wind-speed of 5m/s. This will then allow us to calculate possible efficiency and TSR of the blades. We are aware that the winning team last year produced 18W at 15m/s with a calculated efficiency of around 8-9%. So at least we have goal to aim at. Robert You asked: "What type of load test will be preformed and how is the output measured ? " That is something I am unsure of but will find out tomorrow and will post a reply. Thanks Nick |

||||

| Don B Senior Member Joined: 27/09/2008 Location: AustraliaPosts: 190 |

Hi Nick, Your last post contained some useful information that I will return to shortly, however, there are a few comments that I would like to make first: • A propeller blade is not a turbine blade. The most obvious difference is that a propeller has its lifting surface in the direction of travel, whereas a turbine blade has its lifting surface on the downwind side. But there is much more to it than that. Both turbine and propeller blades need twist to operate efficiently, but the amount of twist from centre to tip differs because of the different angles of attack that apply as the radius from the axis changes. As I noted in my previous post, you can get a propeller to act as a turbine, but you will loose efficiency. If the object of the exercise is to get the most efficient set-up, then you will need to design and make turbine blades suited to your specific application. This is not hard. They can be carved out of wood once you have worked out the shape and angle of the stations from the centre to the tip. Have a look on the internet at blade design before you try to press a propeller into service. Using a propeller as a turbine may look good on film, but then, doesn’t everything? You also will not have learnt anything about the difference. • There are two kinds of balance, static and dynamic. You can statically balance blades but still have an aerodynamic unbalance if the twist or section of each blade is different. Static balance is easy to obtain with a light bolt with a small hole bored through the centre, and some fine thread. The assembled blades are suspended flat with the bolt through the centre, and a nut on the bolt is used to raise the centre of gravity of the blades till they are at the point of toppling. There is information on this forum, and other places, about how to do this. • Two bladed HAWT’s will vibrate as they are yawed to the wind, and this could be confused with unbalance. This effect is not so much of a problem with 3 or more blades, which is why most turbines are three bladed. Three bladed turbines strike the best balance between an acceptably high TSR band, and hence rotational speed, freedom from vibration while yawing, and efficiency, which is why they are commonly used. • You seem to have missed the point concerning tip speed ratio (TSR). It has been empirically determined that there is a limited range of TSR’s in which different numbers of blades will work efficiently. It is not a number plucked out of this air, and you can’t make a turbine work effectively out of its TSR band. As noted in my previous post, a typical TSR for a 3 blade turbine is around 5. This means that the wind incident on the tips of a turbine operating at a design TSR of 5 will have one part of its velocity due to wind speed, and 5 parts of its velocity due to its rotational speed at that radius, and the angle will be artan 1/5, or 11.3 degrees relative to the disc swept out by the blades. The selected TSR is actually the starting point for the blade design, which must then take into account such things as the aerofoil selected, the blade chord at that radius, and the selected angle of attack. • Your concept of exposing an unloaded propeller arrangement to an air stream and then measuring its rpm and trying to back calculate a TSR will not produce any meaningful numbers. The propeller arrangement will be running overspeed compared to what would happen under load, and you can not obtain its design TSR from this information. The best clue as to its TSR would come from measuring the tip angle, and finding its tangent, in the reverse of the above calculation. Returning to the matter of the PMA, the data that you supplied shows that it could output 25 Watts or so, but would need a shaft speed of over 2,200 rpm to do it. This is the problem with small diameter alternators, as they need to spin at this sort of speed to produce anything useful. This is why larger wind turbines are directly coupled to larger diameter axial flux alternators that don’t need to turn so quickly to produce power. It is also instructive to inspect the “Electrical Output Power” curves that you supplied. While these are labeled for a “Trident” generator, I assume that it would be quite similar to the CL66 25 Watt 13604 motor data that you supplied. I note that they only tested the motor down to a 12 Ohm load, and yet the CL66 terminal resistance is quoted at 4.6 Ohms. As noted in my earlier post, the maximum power transfer occurs when the load resistance is equal to the generator winding resistance, and this would need a load down to 4.6 Ohms. Had this generator been tested down to, say, 2 Ohms load resistance, then the output power would have been seen to peak at around 4.6 Ohms, and then again decrease. It would be interesting to get the tests re-run in this way, as then you could see the actual maximum output power. You note three test wind speeds of 5, 10, and 15 m/s. If you selected a 3 blade turbine with a TSR of 5, your turbine tip speeds would therefore be 25, 50, and 75 m/s. If you use the full 400 mm diameter available to you, then your shaft speeds would be 25X60/0.4 Pi, or 1193 rpm, 2387, and 3850 rpm. The first is certainly in the band of being useful, while the others are too fast. If you went for a 6 blade turbine, with a TSR of around 2 to 3, then the respective turbine shaft speeds would drop to half of the above values. Note though, that there would also be a turbine efficiency loss. Note also that the shaft speeds are only part of the picture. What you now need to do is to go to a “Power in the wind” site, and look at what power you can get out of a 400 mm diameter turbine at the 3 velocities in question. As previously noted, you will probably be looking at an efficiency of something below 30%. The power available at 5 m/s will probably be quite disappointing but, above that, the cube law for power vs velocity will make it much more useful. Please post your outcomes. Regards Don B |

||||

| yahoo2 Guru Joined: 05/04/2011 Location: AustraliaPosts: 1166 |

If there is no fine print in the rules to say that the turbine needs to generate power from any wind direction that would open up many more possibilities for mechanically governing the RPM and avoiding surging. Presumably testing is with a big fan. wind from a fixed direction venturi or air pump and a diaphragm to furl the head controlled with restrictors, pulsing solenoids or bleed valves. air pump or hydraulics on the shaft that can be restricted to slow the blades enclosed fan can be restricted to let the fan run with no load sense the wind with a spring loaded or gravity flap as a control mechanism shade part of the outer edge of the blade circumference, 90 % of the power is generated in the outer third or less. sense the revs and use an actuator to ??? hinge the head vertically to furl If you are thinking about 6 blades perhaps something like this may push your buttons dual rotor mount the rotors on a single supported shaft for strength (3 bearings) and drive the motor with a pulley. It needs to be at a slight angle to the wind so that both rotors catch clean linear air. if there is no turbulence prevention in the test rig it may not matter that much. cheers yahoo I'm confused, no wait... maybe I'm not... |

||||

| Don B Senior Member Joined: 27/09/2008 Location: AustraliaPosts: 190 |

Hi again Nick, With a couple more idle moments, I have calculated the power available in a disc of wind of 400 mm diameter at your three speeds of 5, 10, and 15 m/s. In metric dimensions, the formula is Pwind in Watts = 0.5 X sea level density (1.2) X area of disc (0.1256 m2) X wind velocity cubed. This gives the total available wind powers as 9.42, 75.42, and 254 Watts respectively. Assuming that your turbine and alternator set up will be 20% efficient, you could possibly get 1.8, 15.0, and 50.9 Watts out at those 3 wind speeds. I hope that you will not just take my word for it, but will independently check these figures. Incidentally, you mention that a previous team achieved 18 Watts at 15 m/s, so that you should have plenty of upside Watts available if you are prepared to apply proper design principles. You also mention that they had a calculated efficiency of 8 to 9%, but I wonder how that was calculated, in particular, where did their power input figure come from? I suggest that you use the full 400mm diameter available to you, and carefully design a 6 blade turbine for a TSR of about 2.5. Regards Don B |

||||